Separation and purification method of all component monomers of Dalbavancin key intermediate A40926

An A40926, separation and purification technology, used in the field of medicine, can solve the problems of high cost, difficult to industrialize amplification, small sample loading volume, etc., and achieve the effects of improved efficiency, large sample loading, and safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

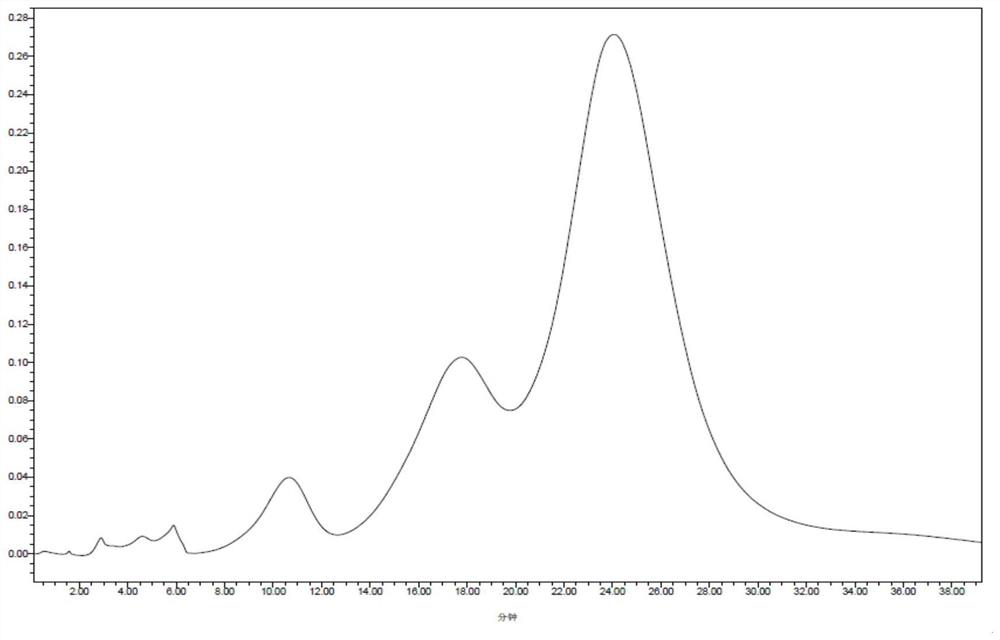

Image

Examples

Embodiment 1

[0029] The 35L fermentation broth was added with 2mol / L sodium hydroxide solution to adjust the pH value to 12.0, and stirred for 30min. Take 1ml of the sample and centrifuge to take the supernatant for HPLC analysis and determination. The A40926 B0 fraction is 42.8g. Pour the fermentation broth into the ceramic membrane filtration equipment (ceramic membrane pore size is 0.1um), and control the temperature of the fermentation broth to be lower than 30°C for filtration. When the volume of the fermentation broth is lower than 20L, slowly add 180L of alkaline water with a pH value of 12.0 to maintain fermentation. The liquid volume is about 20L. The filtrate after the ceramic membrane filtration was adjusted to pH 8.0 with 1 mol / L hydrochloric acid, and the sample was loaded on a polyamide column (15CM*70CM) at a speed of 4BV / hr. After the sample was loaded, 3BV pure water, 5BV 1% ammonia water and 2% ammonia water of 5BV were eluted, and the eluates containing A40926 were comb...

Embodiment 2

[0031] The 50L fermentation broth was added with ammonia water to adjust the pH value to 11.0, and stirred for 30min. Take 1ml of the sample and centrifuge to take the supernatant for HPLC analysis and determination. The A40926 B0 fraction is 57.5g. Pour the fermentation broth into the ceramic membrane filtration equipment (ceramic membrane pore size 0.2um), control the temperature of the fermentation broth to be lower than 30°C for filtration, when the volume of the fermentation broth is lower than 20L, slowly add 180L of alkaline water with a pH value of 11.0 to maintain fermentation The liquid volume is about 20L. The filtrate after the ceramic membrane filtration was adjusted to pH 7.0 with 1 mol / L sulfuric acid, and the sample was loaded on a polyamide column (15CM*70CM) at a speed of 5BV / hr. After the sample was loaded, 3BV pure water, 10BV 10 BV of NaOH aqueous solution at pH 10, 10BV of pH 12 aqueous NaOH solution. The eluates containing A40926 were pooled. The elua...

Embodiment 3

[0033]45 L of fermentation broth was added with 1 mol / L potassium hydroxide solution to adjust the pH value to 13.0, and stirred for 30 min. Take 1ml of the sample and centrifuge to take the supernatant for HPLC analysis and determination. The A40926 B0 fraction is 52.9g. Pour the fermentation broth into the ceramic membrane filtration equipment (ceramic membrane pore size 0.05um), control the temperature of the fermentation broth to be lower than 25°C for filtration, when the volume of the fermentation broth is lower than 20L, slowly add 200L of alkaline water with a pH value of 13.0 to maintain fermentation The liquid volume is about 20L. The filtrate after the ceramic membrane filtration was adjusted to pH 7.0 with 1 mol / L phosphoric acid, and the sample was loaded on a polyamide column (15CM*70CM) with a sample loading speed of 3BV / hr. 5% urea in water and 8BV in 20% urea in water. The eluates containing A40926 were pooled. The eluate was adjusted to pH 3.2 with phospho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com