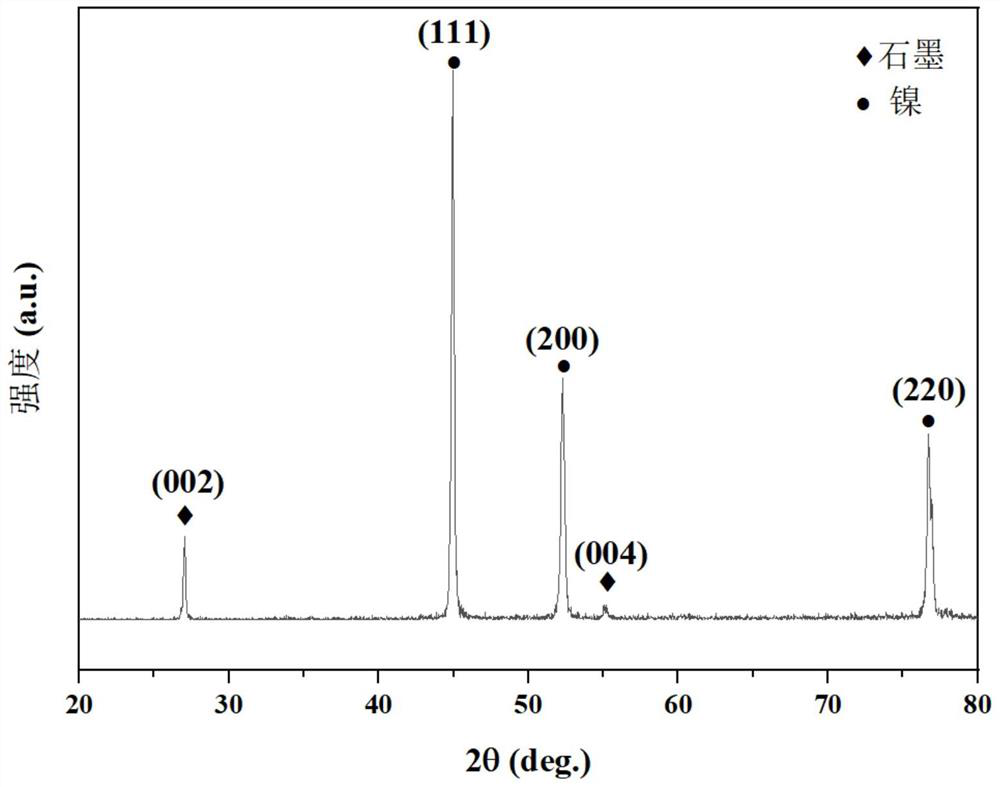

Preparation method of nickel-coated graphite composite particles and application of nickel-coated graphite composite particles in field of electromagnetic shielding

A composite particle, nickel-coated graphite technology, applied in the fields of magnetic field/electric field shielding, electrical components, liquid chemical plating, etc., can solve the problems of poor plating solution stability, high conductive path, poor electromagnetic performance, etc., and achieve good oxidation resistance. , low internal stress, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method of nickel-coated graphite composite particles, the specific implementation steps are as follows:

[0033] Step 1: Place 1 g of flake graphite matrix with a particle size of 100 μm in 500 ml of sodium hydroxide solution with a concentration of 80 g / L for heating and stirring, the heating temperature is 50 °C, and the stirring time is 30 min. After finishing the degreasing and cleaning pretreatment, it was then placed in a vacuum drying box at 40°C and dried for 12 hours before use;

[0034] Step 2: Prepare an electroless nickel plating solution, and use a sodium hydroxide solution to adjust the pH of the plating solution to 12. In the plating solution, the nickel sulfate concentration is 16g / L, the potassium sodium tartrate concentration is 9.4g / L, the sodium citrate concentration is 23.5g / L, and the hydrazine hydrate concentration is 10g / L. In this embodiment, potassium sodium tartrate and sodium citrate are The mass ratio of addition amount is 1:2...

Embodiment 2

[0039] A preparation method of nickel-coated graphite composite particles, the specific implementation steps are as follows:

[0040] Step 1: Place 1.5g of flake graphite matrix with a particle size of 100μm in 500ml of sodium hydroxide solution with a concentration of 100g / L for heating and stirring, the heating temperature is 60°C, and the stirring time is 45min. The graphite substrate was pretreated for degreasing and cleaning, and then placed in a vacuum drying box at 60 °C for 16 hours for use;

[0041] Step 2: Prepare an electroless nickel plating solution, and use a sodium hydroxide solution to adjust the pH of the plating solution to 12.5. In the plating solution, the nickel sulfate concentration is 20g / L, the potassium sodium tartrate concentration is 15g / L, the sodium citrate concentration is 52.5g / L, and the hydrazine hydrate concentration is 15g / L. In this embodiment, potassium sodium tartrate and sodium citrate are added. The mass-to-mass ratio is 1:3.5.

[0042...

Embodiment 3

[0045] A preparation method of nickel-coated graphite composite particles, the specific implementation steps are as follows:

[0046] Step 1: The flake graphite matrix with a particle size of 150 μm was placed in 500 ml of sodium hydroxide solution with a concentration of 95 g / L for heating and stirring, the heating temperature was 70 °C, and the stirring time was 45 min. After finishing the degreasing and cleaning pretreatment, it was then placed in a vacuum drying box at 60 °C for 16 hours for use;

[0047] Step 2: Prepare an electroless nickel plating solution, and use a sodium hydroxide solution to adjust the pH of the plating solution to 13. In the plating bath, the nickel sulfate concentration is 45g / L, the potassium sodium tartrate concentration is 24g / L, the sodium citrate concentration is 96g / L, and the hydrazine hydrate concentration is 22g / L. In this embodiment, the potassium sodium tartrate and the sodium citrate addition are The mass ratio is 1:4.

[0048] Step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com