Preparation method of high-strength and high-toughness bionic fiber

A fiber and high-strength technology, which is applied in the field of preparation of high-strength and high-toughness bionic fibers, can solve the problems of difficulty in effectively improving the strength and toughness of polyurethane fibers, weak interfacial force, and deterioration of mechanical properties, achieving high practical application value and increasing interfacial interaction. Powerful and controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

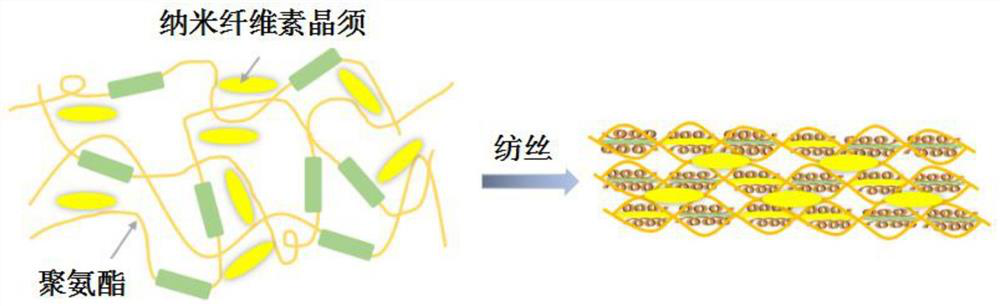

[0032] The invention provides a preparation method of high-strength and high-toughness bionic fiber, comprising the following steps:

[0033]S1. Use a silane coupling agent to modify the surface of the nanocellulose whiskers, then add the modified nanocellulose whiskers into dimethyl sulfoxide, fully disperse and then add thermoplastic polyurethane to form a cast film after fully dissolving liquid;

[0034] S2, drying the film-coating solution obtained in step S1 to obtain a composite film;

[0035] S3, placing the composite membrane obtained in step S2 in a ternary solvent mixed with dimethyl sulfoxide, N,N-dimethylformamide and toluene, and fully dissolving to form a spinning dope; adopt a wet method Spinning technology, the spinning thin stream formed after the spinning stock solution passes through the spinneret enters the coagulation bath, and is coagulated and formed into primary fibers under a predetermined drafting multiple;

[0036] S4. The nascent fibers obtained i...

Embodiment 1

[0045] The present embodiment provides a method for preparing high-strength and high-toughness bionic fibers, comprising the following steps:

[0046] S1. Preparation of casting liquid

[0047] After mixing absolute ethanol and water according to the mass ratio of 8:2, add the silane coupling agent γ-aminopropyltrimethoxysilane, adjust the pH to 4.0, and stir at room temperature for 30 minutes to obtain the mass of the silane coupling agent. Fraction of 3% hydrolyzate. Then add nanocellulose whiskers with a length of 200nm and a diameter of 12nm to the hydrolyzate according to the mass ratio of nanocellulose to hydrolyzate 3:100, stir at room temperature for 3h, wash with absolute ethanol, and dry to obtain a modified Post-sexualized nanocellulose whiskers.

[0048] Then, the modified nanocellulose whiskers are added into dimethyl sulfoxide, mechanically stirred, and then ultrasonically dispersed to make them fully dispersed; then thermoplastic polyurethane is added, and aft...

Embodiment 2~9

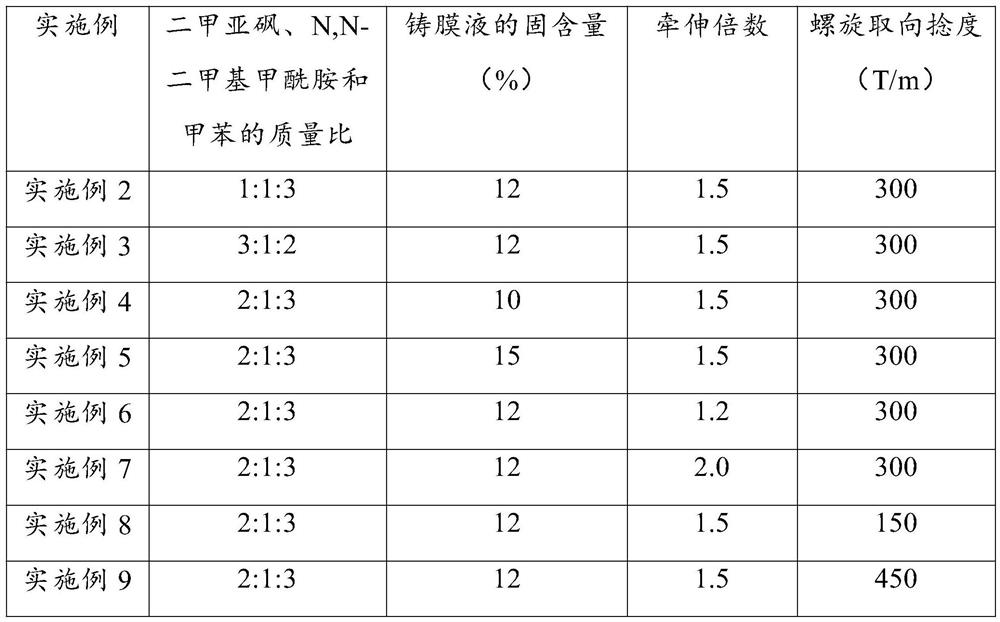

[0057] Embodiments 2 to 9 respectively provide a preparation method of high-strength and high-toughness bionic fibers. Compared with embodiment 1, the difference is that the process parameters of the preparation process are changed. The specific parameters corresponding to each embodiment are shown in Table 1. , the remaining steps and parameters are the same as those in Embodiment 1, and are not repeated here.

[0058] The process parameters of table 1 embodiment 2~9

[0059]

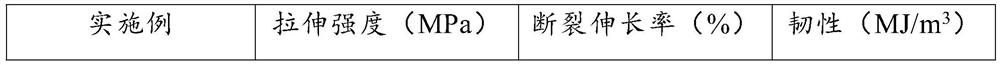

[0060] After testing the properties of the high-strength and high-toughness biomimetic fibers prepared in Examples 2 to 9, compared with Example 1, the results of the relative increase in mechanics are shown in Table 2.

[0061] Table 2 Performance parameters of high-strength and high-toughness biomimetic fibers prepared in Examples 2-9

[0062]

[0063]

[0064] It can be seen from Table 2 that the adjustment of the process parameters in the preparation process will affect the performance of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com