Friction material and product thereof

A technology of friction materials and friction-increasing materials, applied in friction linings, transportation and packaging, machinery and equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

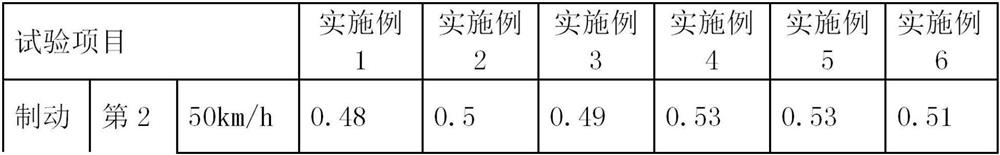

[0030] In order to further explain the technical solutions of the present invention, the present invention will be described in detail below through specific embodiments.

[0031] The invention discloses a friction material, which comprises the following materials: metal material, bonding material, abrasive, fiber-reinforced material, friction-increasing material, friction-reducing material, functional reinforcement material and other fillers;

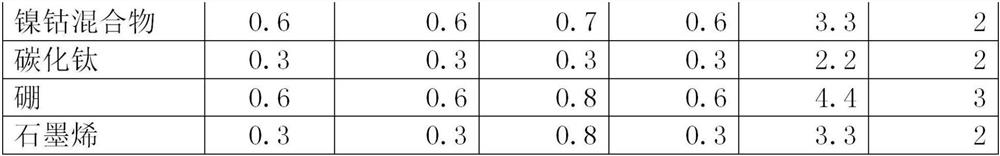

[0032] Metal materials include copper powder and iron powder; bonding materials include resin; abrasives include diamond powder, zirconium corundum powder and potassium feldspar powder; fiber reinforcement materials include metal fibers and non-metal fibers; friction-increasing materials include gallium nitride, aluminum nitride, One or more combinations of boron nitride, silicon nitride, silicon boride, tantalum carbide, hafnium carbide, zirconium boride, and titanium boride; friction-reducing materials include graphite powder, magnesi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com