Nickel-coated sulfur-manganese-cadmium plasma photocatalyst rich in sulfur vacancies as well as preparation method and application of nickel-coated sulfur-manganese-cadmium plasma photocatalyst

A technology of wrapping sulfur, manganese, cadmium, and plasma, which is applied in the field of photocatalytic materials, can solve the problems of reducing the height of the Schottky junction, and achieve the effects of promoting industrial application, reducing production costs, and improving hydrogen production activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

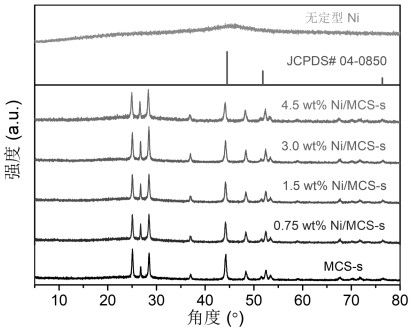

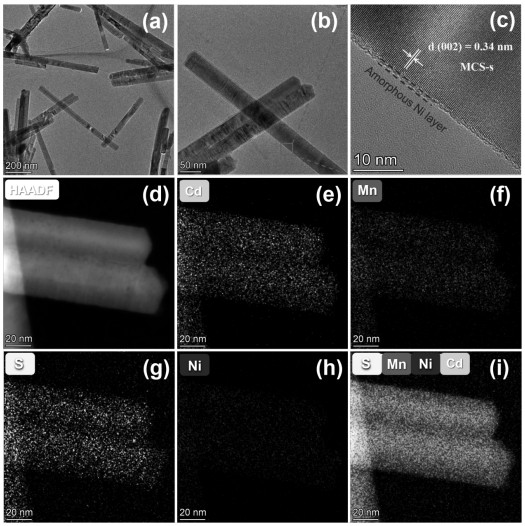

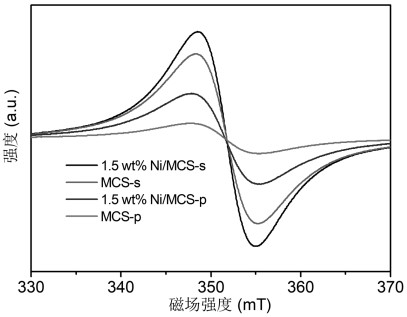

[0029] (1) Solvothermal preparation of sulfur-vacancy-rich Mn 0.3 Cd 0.7 S nanorods

[0030] Dissolve 14 mmol of cadmium acetate and 6 mmol of manganese acetate in a mixed solvent of 30 mL of ethylenediamine and 30 mL of deionized water, stir for 20 min, add 25 mmol of thioacetamide and continue stirring for 30 min, then mix the resulting mixture. The solution was transferred to a 100 mL autoclave, reacted at a constant temperature of 200 °C for 24 h, and cooled to room temperature naturally. The obtained precipitate was washed three times with deionized water and ethanol in turn, and then vacuum-dried at 60 °C overnight to obtain Mn. 0.3 Cd 0.7 S nanorods (MCS-s) powder.

[0031] (2) Preparation of Ni / Mn by solvothermal method 0.3 Cd 0.7 S composite photocatalyst

[0032] Weigh the Mn obtained in step (1) 0.3 Cd 0.7 50 mg of S nanorod (MCS-s) powder was dispersed in 80 ml of ethanol solution and stirred for 10 min, and 64 µL of 0.1 mol / L Ni(NO) was added. 3 ) 2After...

Embodiment 2

[0034] (1) Solvothermal preparation of sulfur-vacancy-rich Mn 0.3 Cd 0.7 S nanorods

[0035] Dissolve 14 mmol of cadmium acetate and 6 mmol of manganese acetate in a mixed solvent of 30 mL of ethylenediamine and 30 mL of deionized water, stir for 20 min, add 25 mmol of thioacetamide and continue stirring for 30 min, then mix the resulting mixture. The solution was transferred to a 100 mL autoclave, reacted at a constant temperature of 200 °C for 24 h, and cooled to room temperature naturally. The obtained precipitate was washed three times with deionized water and ethanol in turn, and then dried in vacuum at 60 °C overnight to obtain Mn. 0.3 Cd 0.7 S nanorods (MCS-s) powder.

[0036] (2) Preparation of Ni / Mn by solvothermal method 0.3 Cd 0.7 S composite photocatalyst

[0037] Weigh the Mn obtained in step (1) 0.3 Cd 0.7 50 mg of S nanorod (MCS-s) powder was dispersed in 80 ml of ethanol solution and stirred for 10 min, and 128 µL of 0.1 mol / L Ni(NO) was added. 3 ) 2 ...

Embodiment 3

[0039] (1) Solvothermal preparation of sulfur-vacancy-rich Mn 0.3 Cd 0.7 S nanorods

[0040] Dissolve 14 mmol of cadmium acetate and 6 mmol of manganese acetate in a mixed solvent of 30 mL of ethylenediamine and 30 mL of deionized water, stir for 20 min, add 25 mmol of thioacetamide and continue stirring for 30 min, then mix the resulting mixture. The solution was transferred to a 100 mL autoclave, reacted at a constant temperature of 200 °C for 24 h, and cooled to room temperature naturally. The obtained precipitate was washed three times with deionized water and ethanol in turn, and then dried in vacuum at 60 °C overnight to obtain Mn. 0.3 Cd 0.7 S nanorods (MCS-s) powder.

[0041] (2) Preparation of Ni / Mn by solvothermal method 0.3 Cd 0.7 S composite photocatalyst

[0042] Weigh the Mn obtained in step (1) 0.3 Cd 0.7 50 mg of S nanorod (MCS-s) powder was dispersed in 80 ml of ethanol solution and stirred for 10 min, and 256 µL of 0.1 mol / L Ni(NO) was added. 3 ) 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com