Cobalt-free positive electrode material, preparation method thereof and lithium ion battery

A positive electrode material and ion technology, applied in the field of cobalt-free positive electrode materials and its preparation, can solve the problems of slow migration speed of lithium ions, refractory oxidation of divalent nickel ions, and increased cost of operation process, so as to increase the reactive surface area and reduce the Irreversible loss for the first time, effect in favor of diffusion transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

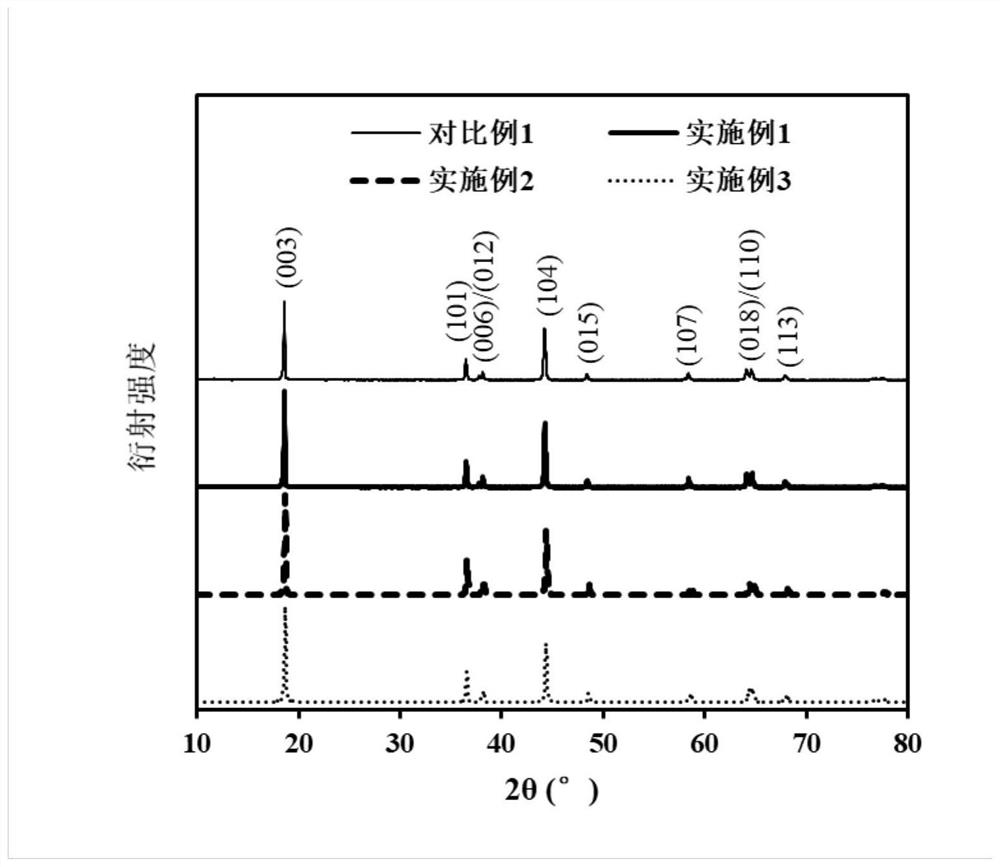

[0063] The present embodiment provides a preparation method of a cobalt-free positive electrode material and the obtained cobalt-free positive electrode material, the details are as follows:

[0064] Dissolve nickel sulfate and manganese sulfate in deionized water to obtain solutions with concentrations of 1.6 mol / L and 0.2 mol / L, respectively, and mix the two solutions evenly to obtain a nickel-manganese mixed salt solution; dissolve lithium hydroxide to remove The concentration of the solution obtained in the ionized water is 3mol / L; the graphene oxide hydrogel is dissolved in deionized water to obtain a solution of 0.25mol / L, wherein lithium ion, nickel ion, manganese ion in lithium hydroxide, nickel sulfate, manganese sulfate solution The ion molar ratio is 30:0.6:0.4; prepare 2.0mol / L ammonia solution and 12.0mol / L sodium hydroxide solution;

[0065] The above-mentioned five kinds of filtered solutions are added into the reactor in parallel according to the flow velocity ...

Embodiment 2

[0068] The present embodiment provides a preparation method of a cobalt-free positive electrode material and the obtained cobalt-free positive electrode material, the details are as follows:

[0069]Dissolve nickel sulfate and manganese sulfate in deionized water to obtain solutions with concentrations of 1.8 mol / L and 1.1 mol / L, respectively, and mix the two solutions evenly to obtain a nickel-manganese mixed salt solution; dissolve lithium nitrate in deionized water The concentration of the solution obtained in the water is 4mol / L; the graphene oxide hydrogel is dissolved in deionized water to obtain a solution of 1.5mol / L, wherein, in the lithium nitrate, nickel sulfate, and manganese sulfate solution, the moles of lithium ions, nickel ions, and manganese ions are The ratio is 40:0.8:0.2; prepare 1.0mol / L ammonia solution and 13.0mol / L sodium hydroxide solution;

[0070] The above-mentioned five kinds of filtered solutions are added to the reactor in parallel according to t...

Embodiment 3

[0073] The present embodiment provides a preparation method of a cobalt-free positive electrode material and the obtained cobalt-free positive electrode material, the details are as follows:

[0074] Dissolve nickel sulfate and manganese sulfate in deionized water to obtain solutions with concentrations of 1.8 mol / L and 0.1 mol / L, respectively, and mix the two solutions evenly to obtain a nickel-manganese mixed salt solution; deionized aluminum chloride The concentration of the solution obtained by dissolving in water is 0.1mol / L; the concentration of the solution obtained by dissolving lithium acetate in deionized water is 5mol / L; the graphene oxide hydrogel is dissolved in deionized water to obtain a solution of 1.8mol / L, wherein, The molar ratio of lithium ion, nickel ion, manganese ion and aluminum ion in lithium acetate, nickel sulfate, manganese sulfate, and aluminum chloride solution is 50:0.95:0.04:0.01; sodium hydroxide solution;

[0075] The above-mentioned six kind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com