Soil treatment method

A technology for soil and soil moisture content, applied in the field of soil treatment, can solve the problems of accelerated soil compaction, single function, and unsatisfactory soil treatment effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

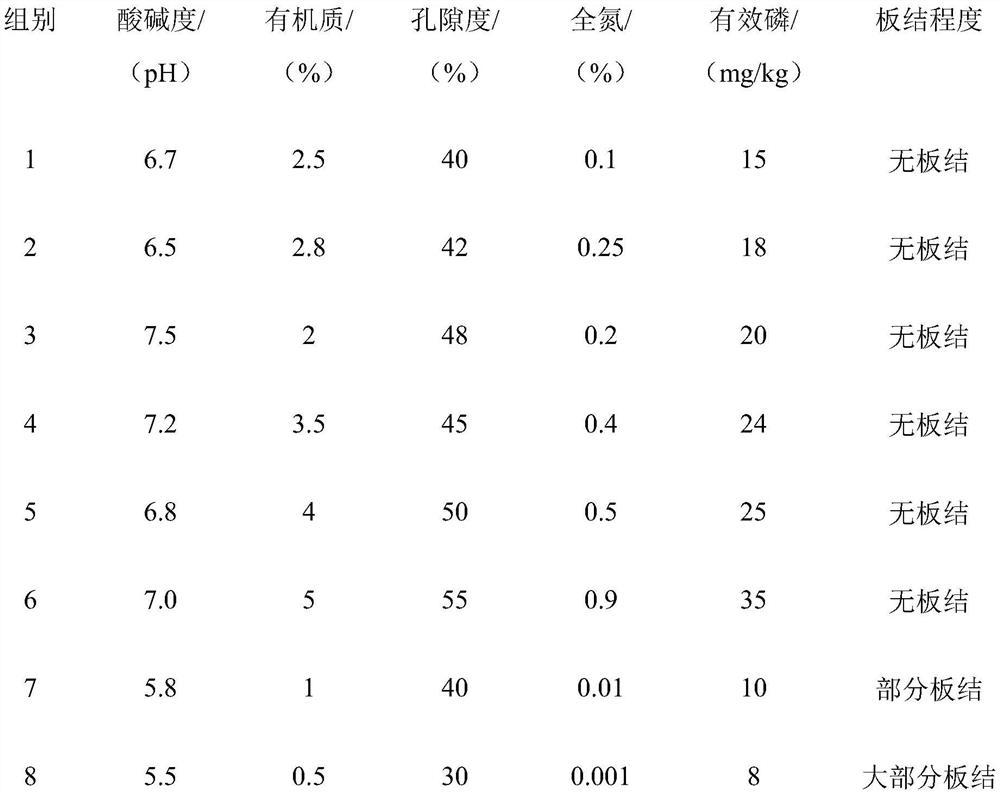

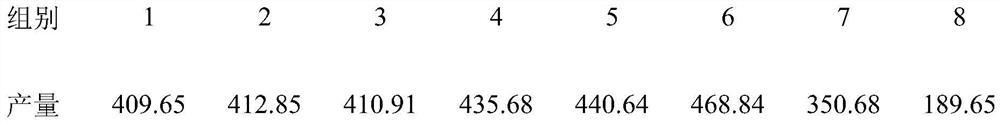

Examples

preparation example Construction

[0026] The preparation method of the enzyme fertilizer includes: mixing bone meal, oil residue, mineral powder and potassium fulvic acid, heating at 80-90°C for 20-30min, then cooling to 30-35°C, adding peel, actinomycetes, Trichoderma and Bacillus subtilis was stirred and fermented for 5-10 days, and chitosan was added every 1-2 days during the fermentation process.

[0027] Through the above preparation method, several can be fully fermented as much as possible, the nutrient content in the enzyme fertilizer can be significantly increased, and the situation of insufficient soil fertility can be improved. And under the above conditions, the raw material structure will not be damaged, and better quality enzyme fertilizer can be obtained, thereby enhancing the soil improvement effect of the enzyme fertilizer.

[0028] The microbial fertilizer includes the following raw materials in parts by weight: 30-40 parts of Bacillus complex, 20-30 parts of Lactobacillus acidophilus, 15-20 ...

Embodiment 1

[0035] A soil treatment method, comprising the following steps:

[0036] First wet the soil with water to make the soil moisture content 30%, then apply enzyme fertilizer and microbial fertilizer to the soil, the mass ratio of enzyme fertilizer and microbial fertilizer is 2:3, plough, and then bury it in the soil The heating module and the slow-release rod were reacted at 40°C for 20 days. After the reaction, the seaweed solution was sprayed into the soil twice, once every 10 days, and the dosage was 10m each time. 3 / mu, the soil is ploughed after each spraying, and high-pressure air is applied to the soil while ploughing the soil.

[0037] In this embodiment, the enzyme fertilizer includes the following raw materials: 50kg of peel, 20kg of chitosan, 40kg of bone meal, 35kg of oil residue, 25kg of mineral powder and 20kg of potassium fulvic acid. The preparation method of the enzyme fertilizer includes: mixing bone meal, oil residue, mineral powder and potassium fulvic acid,...

Embodiment 2

[0040] A soil treatment method, comprising the following steps:

[0041] First wet the soil with water to make the soil moisture content 40%, then apply enzyme fertilizer and microbial fertilizer to the soil, the mass ratio of enzyme fertilizer and microbial fertilizer is 2:7, plough, and then bury it in the soil The heating module and the slow-release rod were reacted at 50°C for 30 days. After the reaction, the alginate solution was sprayed into the soil 4 times, once every 15 days, and the dosage was 20m each time. 3 / mu, the soil is ploughed after each spraying, and high-pressure air is applied to the soil while ploughing the soil.

[0042] In this embodiment, the enzyme fertilizer includes the following raw materials: 60kg of peel, 30kg of chitosan, 50kg of bone meal, 45kg of oil residue, 35kg of mineral powder and 30kg of potassium fulvic acid. The preparation method of the enzyme fertilizer includes: mixing bone meal, oil residue, mineral powder and potassium fulvic ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com