3D printing bone defect repair stent and preparation method thereof

A technology of 3D printing and bone printing, which is applied in the direction of processing and manufacturing, manufacturing auxiliary devices, prostheses, etc., can solve the problems of poor mechanical strength and low immunogenicity, and achieve regular scaffold structure, good uniformity, and easy mixing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

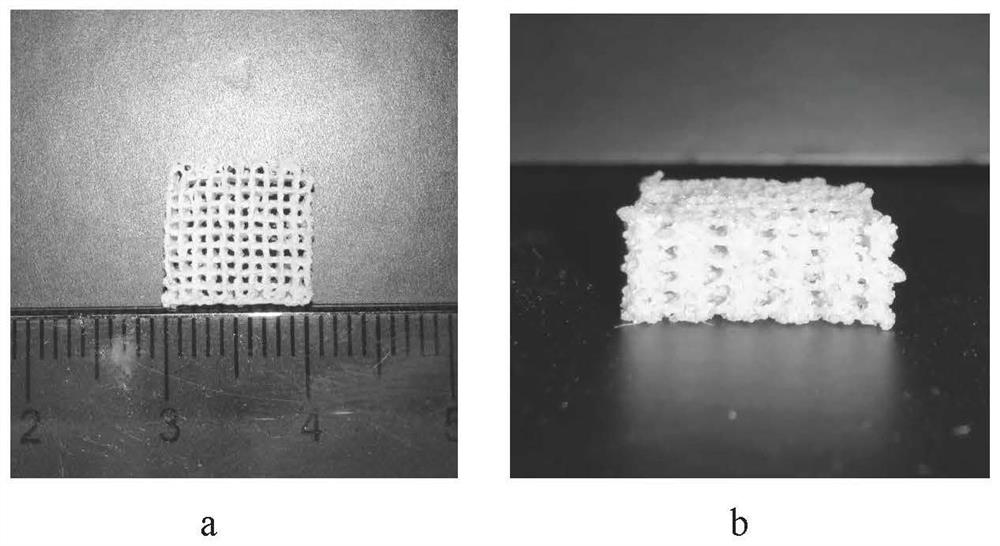

[0038] A 3D-printed bone defect repair scaffold is a multi-layer interconnected porous network structure; the first layer includes a plurality of mutually parallel lines, and the second layer is a plurality of mutually parallel lines vertically connected to the upper surface of the first layer of lines Lines, the third layer is a plurality of mutually parallel lines vertically connected to the upper surface of the lines of the second layer, and so on; the diameter of each layer of lines in the 3D printed bone defect repair scaffold is about 500 μm, and adjacent lines The distance between them is about 700μm;

[0039] The preparation method of the 3D printed bone defect repair scaffold includes the following steps:

[0040] S1. dissolve gelatin, sodium alginate and 58S bioglass in water to obtain a solution, wherein the mass / volume concentration of each component in the solution is 16% gelatin, 6.5% sodium alginate, and 8.5% 58S bioglass;

[0041] S2. Stir the solution evenly ...

Embodiment 2

[0044] A 3D-printed bone defect repair scaffold is a multi-layer interconnected porous network structure; the first layer includes a plurality of mutually parallel lines, and the second layer is a plurality of mutually parallel lines vertically connected to the upper surface of the first layer of lines Lines, the third layer is a plurality of mutually parallel lines vertically connected to the upper surface of the lines of the second layer, and so on; the diameter of each layer of lines in the 3D printed bone defect repair scaffold is about 400 μm, and adjacent lines The distance between them is about 600μm;

[0045] The preparation method of the 3D printed bone defect repair scaffold includes the following steps:

[0046] S1. dissolve gelatin, sodium alginate and 58S bioglass in water to obtain a solution, wherein the mass / volume concentration of each component in the solution is 16% gelatin, 6.5% sodium alginate, and 8.5% 58S bioglass;

[0047] S2. Stir the solution evenly ...

Embodiment 3

[0050] A 3D-printed bone defect repair scaffold is a multi-layer interconnected porous network structure; the first layer includes a plurality of mutually parallel lines, and the second layer is a plurality of mutually parallel lines vertically connected to the upper surface of the first layer of lines Lines, the third layer is a plurality of mutually parallel lines vertically connected to the upper surface of the lines of the second layer, and so on; the diameter of each layer of lines in the 3D printed bone defect repair scaffold is about 400 μm, and adjacent lines The distance between them is about 500 μm;

[0051] The preparation method of the 3D printed bone defect repair scaffold includes the following steps:

[0052] S1. dissolve gelatin, sodium alginate and 58S bioglass in water to obtain a solution, wherein the mass / volume concentration of each component in the solution is 16% gelatin, 6.5% sodium alginate, and 8.5% 58S bioglass;

[0053] S2. Stir the solution evenly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com