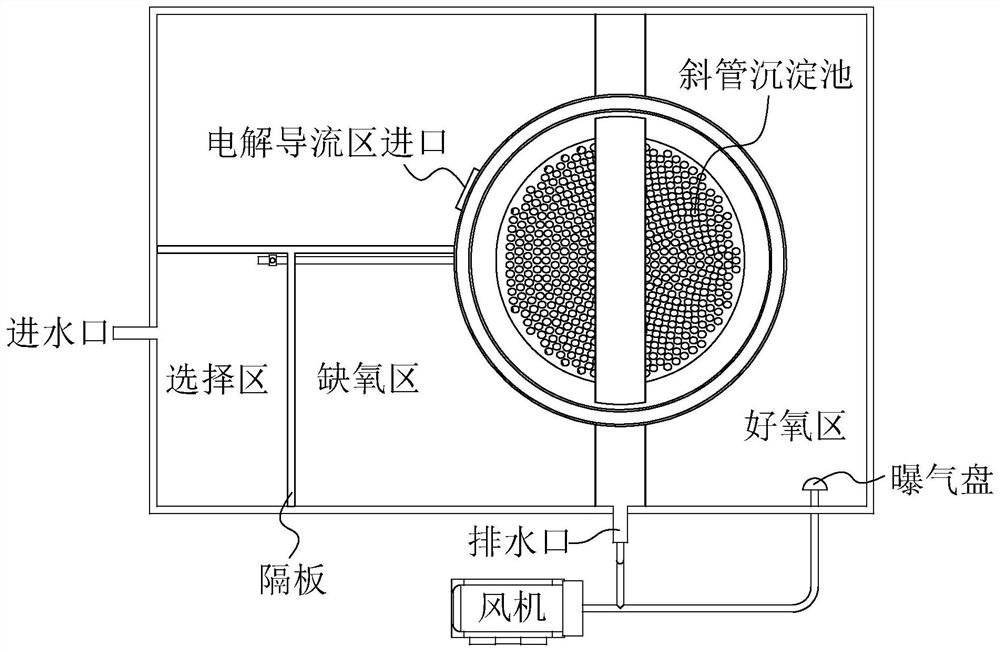

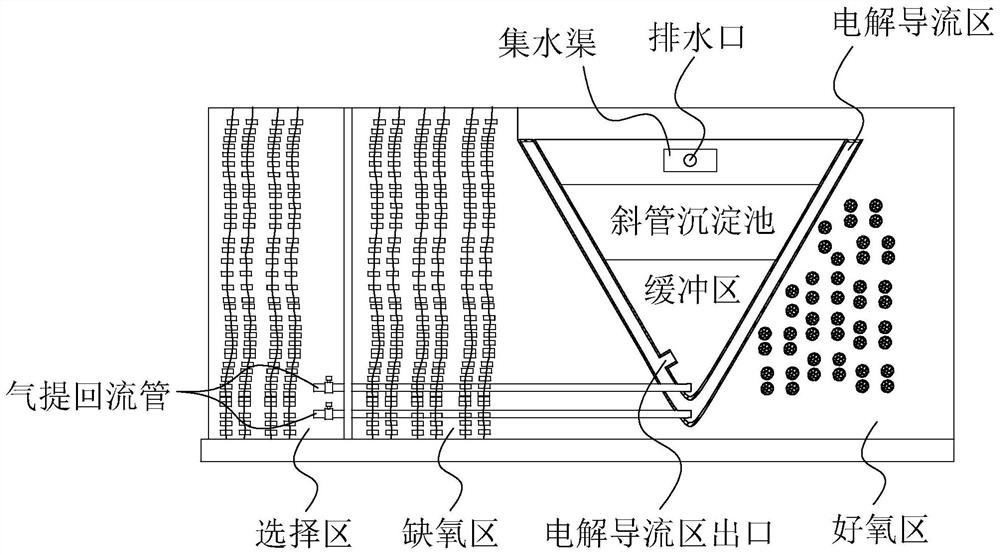

Slow-release solid carbon source, application thereof and sewage treatment device

A solid carbon source, slow-release technology, applied in water/sludge/sewage treatment, anaerobic digestion treatment, water pollutants, etc., can solve problems such as complex system operation, application limitations, and excess, and achieve improved denitrification effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0043] The preparation method of corncob solid carbon source specifically comprises the following steps:

[0044] The corncob is sequentially subjected to washing treatment, cutting treatment, drying treatment, acid treatment, alkali treatment and ultraviolet treatment to obtain the solid carbon source of the corncob.

[0045] Specifically, the washing treatment is to use water to wash the corncob;

[0046] The cutting process is to use a cutting machine to cut the corncob. The size of the cut corncob is (4-5) cm × (1-4) cm × (3-5) cm, and the volume is 40-80 cm. 3 ;

[0047] Drying treatment is to place the corncob in a drying oven with a temperature of 90°C for 24h;

[0048] The acid treatment is that the corncob is soaked in the acid treatment solution for 12 hours and then drained; the solute of the acid treatment solution is sulfuric acid, and the mass percentage concentration of sulfuric acid in the acid treatment solution is 5%;

[0049] The alkali treatment is to so...

preparation example 1~4

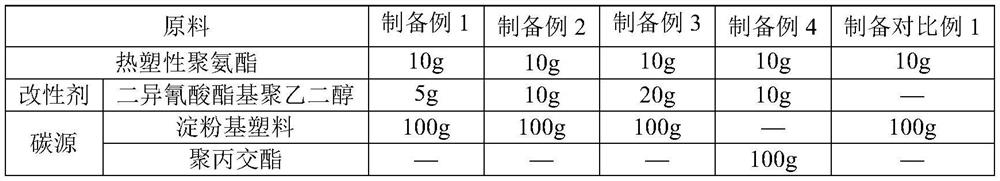

[0066] Preparation Examples 1 to 4 of Polymer Modified Polyurethane Solid Carbon Source and Preparation Comparative Example 1

[0067] The preparation examples 1 to 4 of the polymer-modified polyurethane solid carbon source and the raw material ratios of the preparation comparative example 1 are shown in Table 1.

[0068] Table 1 Raw material ratio of preparation examples 1 to 4 of polymer modified polyurethane solid carbon source and preparation comparative example 1

[0069]

[0070] Examples of slow-release solid carbon sources

[0071] The preparation method of polymer modified polyurethane solid carbon source specifically comprises the following steps:

[0072] The corncob solid carbon source and the polymer-modified polyurethane solid carbon source are fixed in series by using iron wire or steel bar, and the corncob solid carbon source and the polymer-modified polyurethane solid carbon source are evenly distributed on the iron wire or the steel bar, respectively. ...

Embodiment 1~6 and comparative example 1~8

[0074] The raw material ratios of Examples 1 to 6 and Comparative Examples 1 to 8 are shown in Table 2.

[0075] Table 2 Raw material ratios of Examples 1 to 6 and Comparative Examples 1 to 8

[0076]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap