Corrosion-resistant super-hydrophobic copper-nickel composite coating and preparation method and application thereof

A composite coating, super-hydrophobic technology, applied in electrolytic components, electrolytic processes, cells, etc., can solve the problems of high cost and complex preparation methods, reduce surface energy, enhance corrosion resistance and protection performance, and promote the formation of Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0101] The present embodiment provides a corrosion-resistant and super-hydrophobic copper-nickel composite coating and a preparation method thereof. The preparation method includes the following steps:

[0102](1) carry out degreasing treatment, derusting treatment and rinsing successively with Q235B steel plate; The degreasing liquid that described degreasing treatment adopts is the aqueous solution of sodium salt, and described sodium salt is 50g / L sodium hydroxide, 30g / L The combination of sodium carbonate, 20g / L sodium phosphate dodecahydrate and 15g / L sodium silicate nonahydrate; the temperature of the degreasing treatment is 70°C, and the time is 20min; the derusting liquid used in the derusting treatment is 15vt % hydrochloric acid solution, and the temperature of the rust removal treatment is 25 ° C, and the time is 20 min; the rinsing solution used in the rinsing is deionized water;

[0103] (2) Immerse the steel sheet obtained in step (1) in the pre-dip copper soluti...

Embodiment 2

[0113] The present embodiment provides a corrosion-resistant and super-hydrophobic copper-nickel composite coating and a preparation method thereof. The preparation method includes the following steps:

[0114] (1) carry out degreasing treatment, derusting treatment and rinsing successively with Q345B steel plate; The degreasing liquid that described degreasing treatment adopts is the aqueous solution of sodium salt, and described sodium salt is 40g / L sodium hydroxide, 20g / L The combination of sodium carbonate, 10g / L sodium phosphate dodecahydrate and 10g / L sodium silicate nonahydrate; the temperature of the degreasing treatment is 60°C, and the time is 30min; the derusting liquid used in the derusting treatment is 10vt % hydrochloric acid solution, and the temperature of the rust removal treatment is 20 ° C, and the time is 30 min; the rinsing solution used in the rinsing is deionized water;

[0115] (2) Immerse the steel sheet obtained in step (1) in the pre-dip copper solut...

Embodiment 3

[0121] The present embodiment provides a corrosion-resistant and super-hydrophobic copper-nickel composite coating and a preparation method thereof. The preparation method includes the following steps:

[0122] (1) 610L steel plate is subjected to degreasing treatment, derusting treatment and flushing successively; the degreasing liquid used in the degreasing treatment is an aqueous solution of sodium salt, and the sodium salt is 60g / L sodium hydroxide, 40g / L The combination of sodium carbonate, 30g / L sodium phosphate dodecahydrate and 20g / L sodium silicate nonahydrate; the temperature of the degreasing treatment is 75°C, and the time is 10min; the derusting liquid used in the derusting treatment is 20vt % hydrochloric acid solution, and the temperature of the rust removal treatment is 30 ° C, and the time is 10 min; the rinsing solution used in the rinsing is deionized water;

[0123] (2) Immerse the steel sheet obtained in step (1) in the pre-dip copper solution for 20 s, us...

PUM

| Property | Measurement | Unit |

|---|---|---|

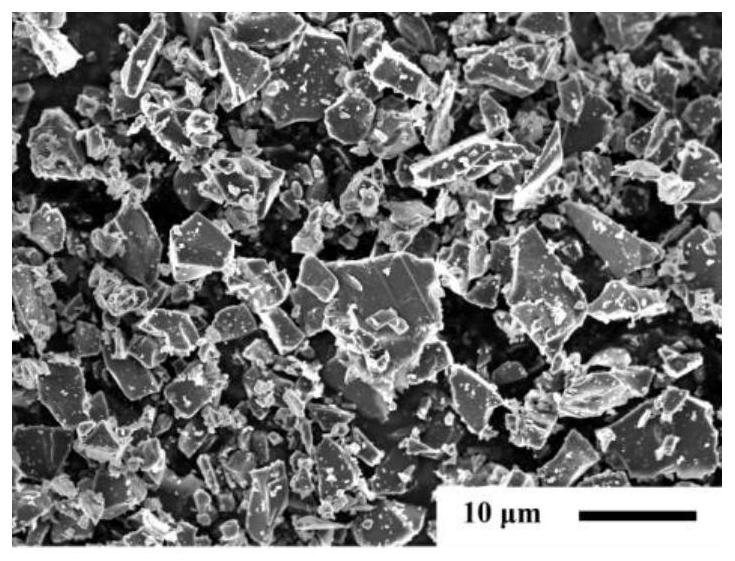

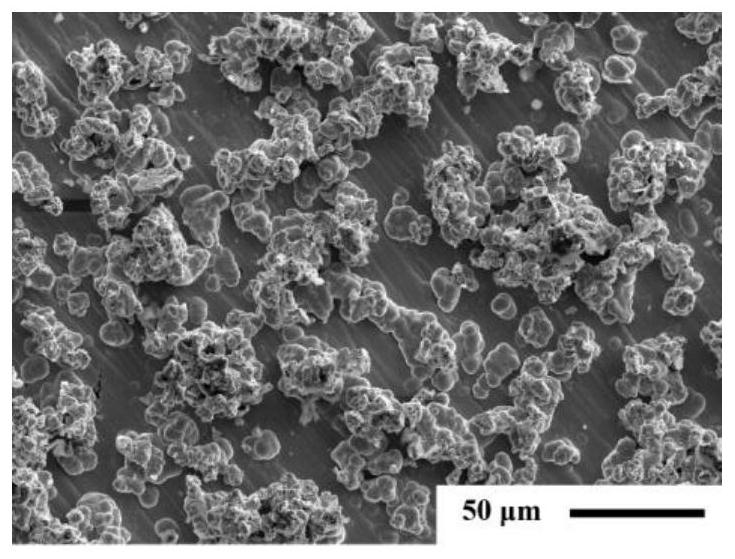

| particle size | aaaaa | aaaaa |

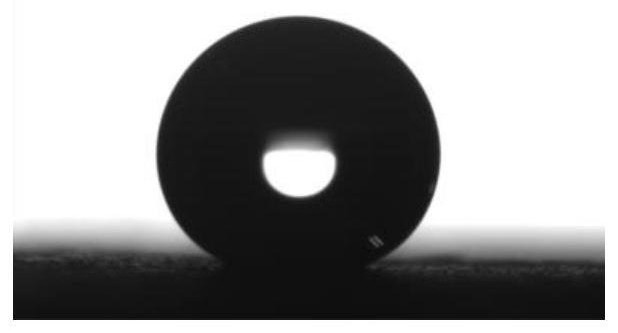

| water contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com