Hydrogenation catalyst and preparation method thereof

A hydrogenation catalyst and hydrogenation reaction technology, applied in chemical instruments and methods, preparation of organic compounds, physical/chemical process catalysts, etc., can solve the problems of low OPP selectivity, short life, low economic benefits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

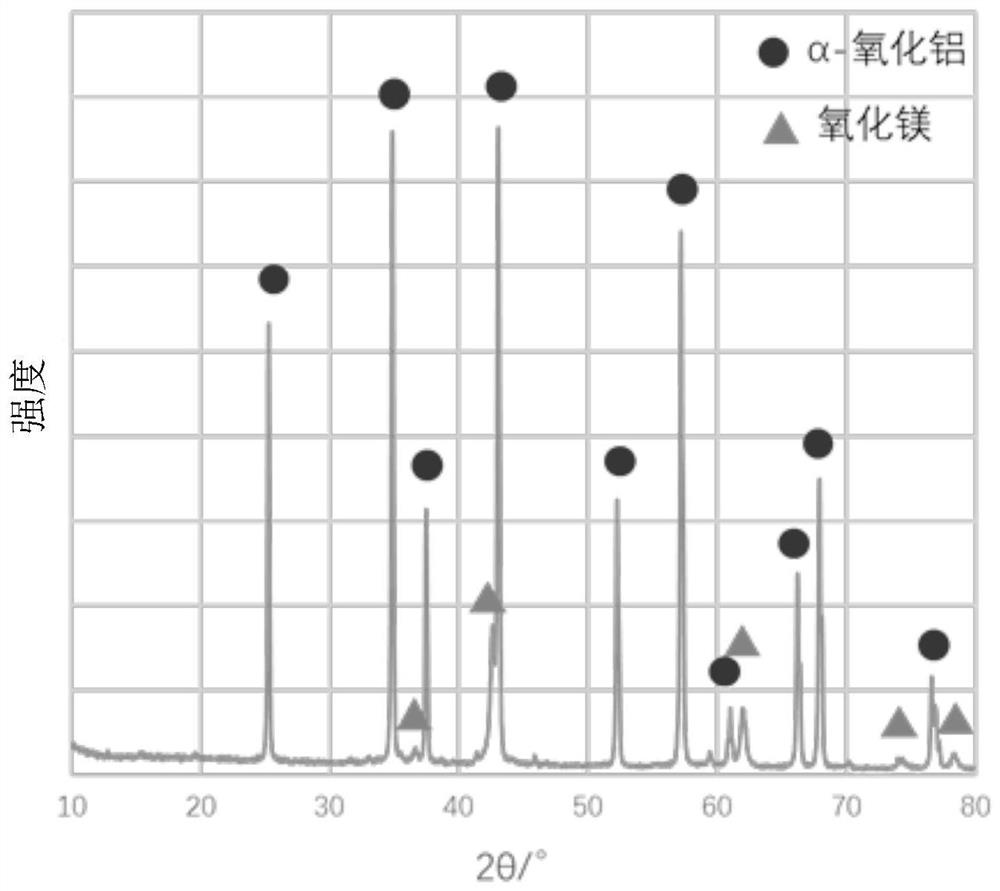

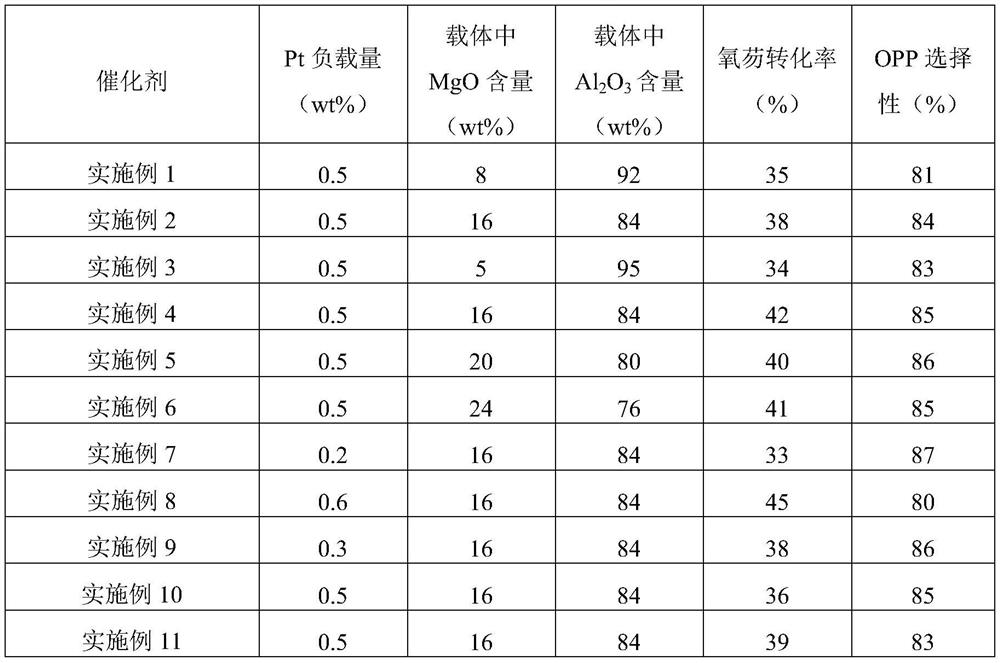

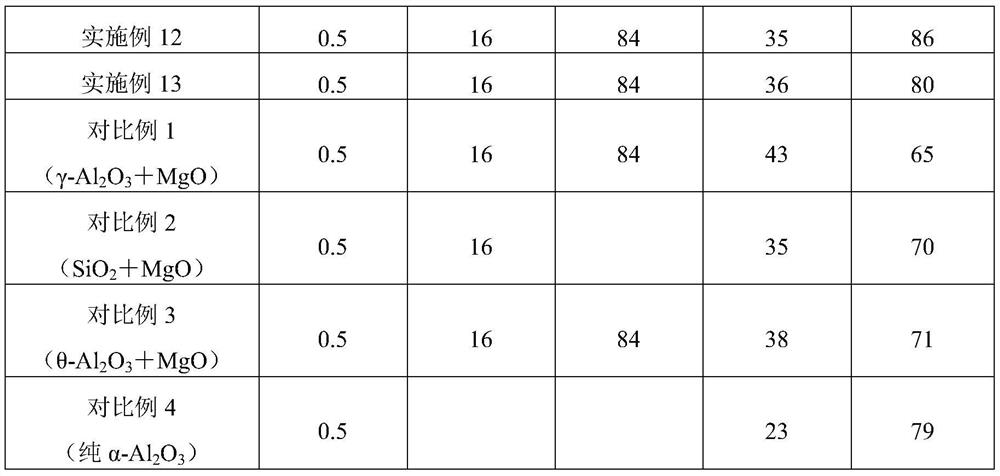

[0082] Take 100g of strip α-Al with a diameter of 3mm 2 O 3 Put it into the sugar coating machine, the speed of the sugar coating machine is 30r / min, and slowly spray 100g of magnesium nitrate aqueous solution with a magnesium nitrate mass fraction of 32% onto the surface of the carrier. During the entire spraying process, the sugar coating machine is blasted and kept at 50 ℃ air temperature , after the spraying of the magnesium nitrate solution is completed, take out the carrier, dry it at 100 °C for 5 h, put the dried sample into the muffle furnace for calcination, and raise the temperature from room temperature to 600 °C at a heating rate of 5 °C / min, and then put it in a muffle furnace. 600 ℃ calcination for 5 hours to obtain MgO-Al 2 O 3 Composite support, in which MgO content is about 8wt%, α-Al 2 O 3 The content is about 92 wt%.

[0083] Take 100g of the above-mentioned composite carrier and put it into the sugar-coating machine. The sugar-coating machine rotates a...

Embodiment 2

[0085] In Example 1, the amount of the magnesium nitrate aqueous solution with a magnesium nitrate mass fraction of 32% was changed to 220 g, and the rest of the preparation method was the same as that of Example 1, and the catalyst of Example 2 was prepared. The content of MgO in the support of the catalyst is about 16wt%, α-Al 2 O 3 The content is about 84 wt%. The Pt loading in the catalyst was 0.5 wt%.

Embodiment 3

[0087] In Example 1, the amount of the magnesium nitrate aqueous solution with a magnesium nitrate mass fraction of 32% was changed to 61 g, and the rest of the preparation method was the same as that of Example 1, and the catalyst of Example 3 was prepared. The content of MgO in the support of the catalyst is about 5wt%, α-Al 2 O 3 The content is about 95 wt%. The Pt loading in the catalyst was 0.5 wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com