Method for preparing high-toughness high-temperature-resistant directionally-arranged silicon nitride monolithic porous ceramic

A technology of silicon nitride monolithic and porous ceramics, which is applied in the field of silicon nitride ceramic sintering, can solve problems such as unsatisfactory performance, achieve the effects of overcoming adverse effects, improving bending strength and fracture toughness, and overcoming high temperature mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

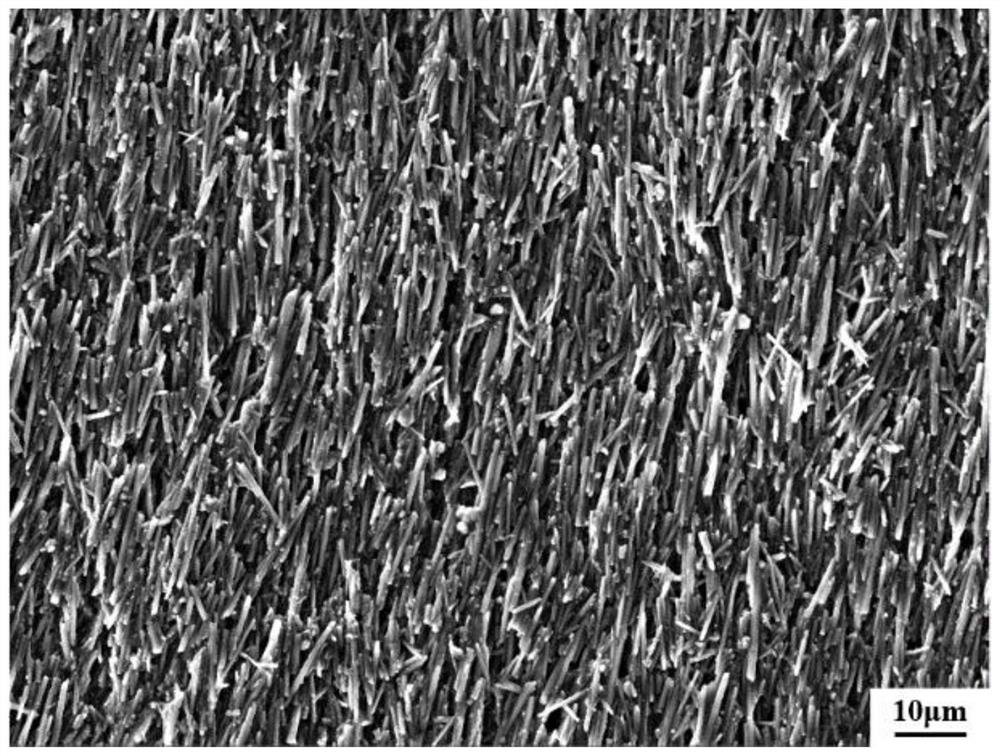

[0074] The microstructure of the cast green sheet prepared in Example 2 is as follows: figure 2 As shown, it can be seen that the micron-scale silicon nitride rod-like crystals with high aspect ratio have strong alignment.

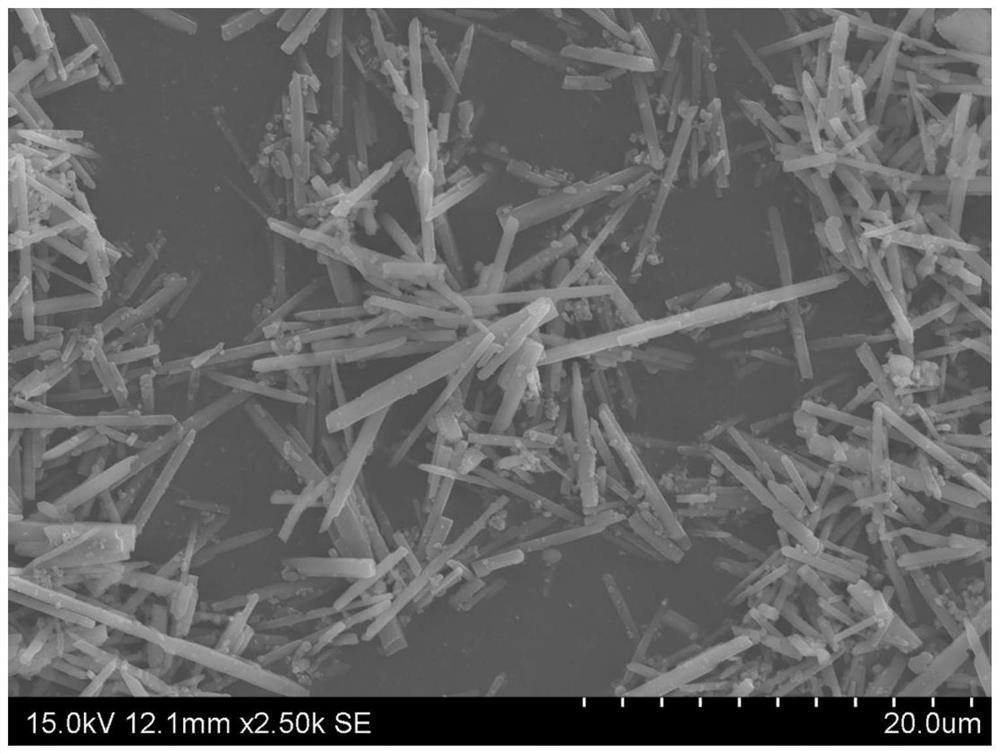

[0075] figure 1 β-Si obtained for Example 2 3 N 4 Seed crystal micrograph. As shown in the figure, the obtained silicon nitride powders all have a high aspect ratio.

[0076] figure 2 Micrograph of the cast sheet obtained for Example 4. As shown, β-Si with high aspect ratio 3 N 4 The seeds have obvious orientation.

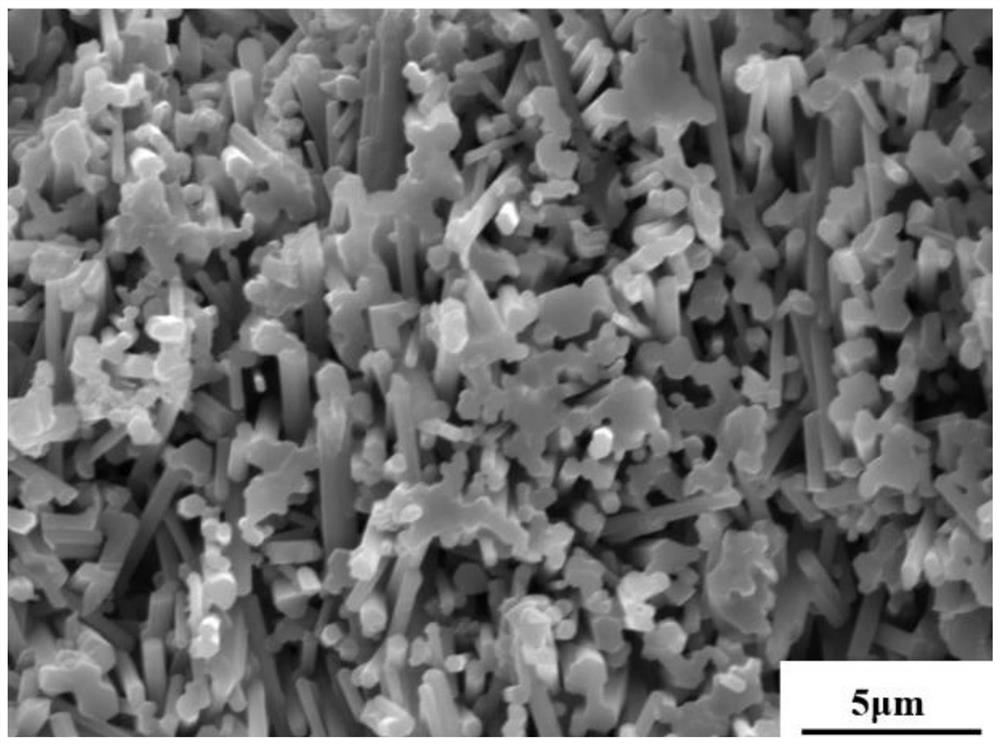

[0077] image 3 For the fracture structure and morphology of Example 6, it can be seen that the fracture structure and morphology are all small particles with a hexagonal cross-section, which also proves that the process of tape casting enables the silicon nitride rod-shaped fibers to be cast along the Better alignment in the direction.

[0078] Figure 4 The XRD pattern of the porous silicon nitride material obtained in Example ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com