Anti-reverse nitrogen-carbon carrier catalyst for proton exchange membrane fuel cell and preparation method of anti-reverse nitrogen-carbon carrier catalyst

A proton exchange membrane and fuel cell technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of electrolytic water oxidation reaction activity decline, instability, unreliable vehicle operation, etc., to achieve stability, easy cleaning, and inhibition Effects of Migration and Reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

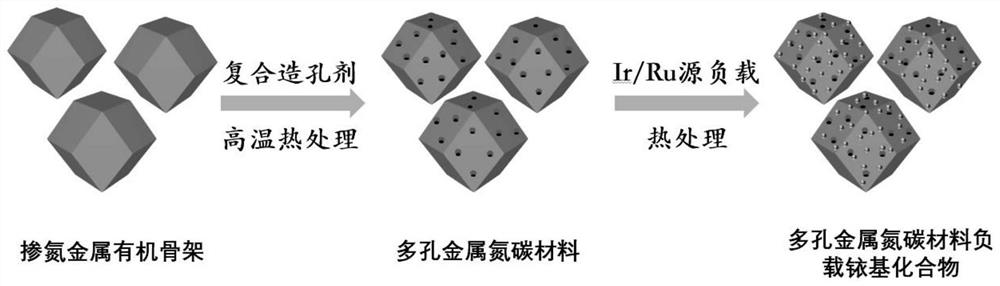

[0036] like figure 1 As shown, the preparation method of the anti-reverse polar nitrogen-carbon supported catalyst for the proton exchange membrane fuel cell according to the embodiment of the present invention includes the following steps:

[0037] a. Dissolving the transition metal salt, the nitrogen source and the carbon source in the first dispersant to obtain a nitrogen-doped metal organic framework;

[0038] b. Dissolving the nitrogen-doped metal-organic framework and the composite pore-forming agent in a second dispersant, mixing and stirring, drying and then placing it in a first sintering atmosphere for sintering treatment to obtain a carrier porous metal nitrogen-carbon material, wherein the The composite pore-forming agent includes a first pore-forming agent and a second pore-forming agent, and the first pore-forming agent includes at least one of ammonium chloride, ammonium carbonate, ammonium sulfate, and ammonium bicarbonate; the second pore-forming agent Includ...

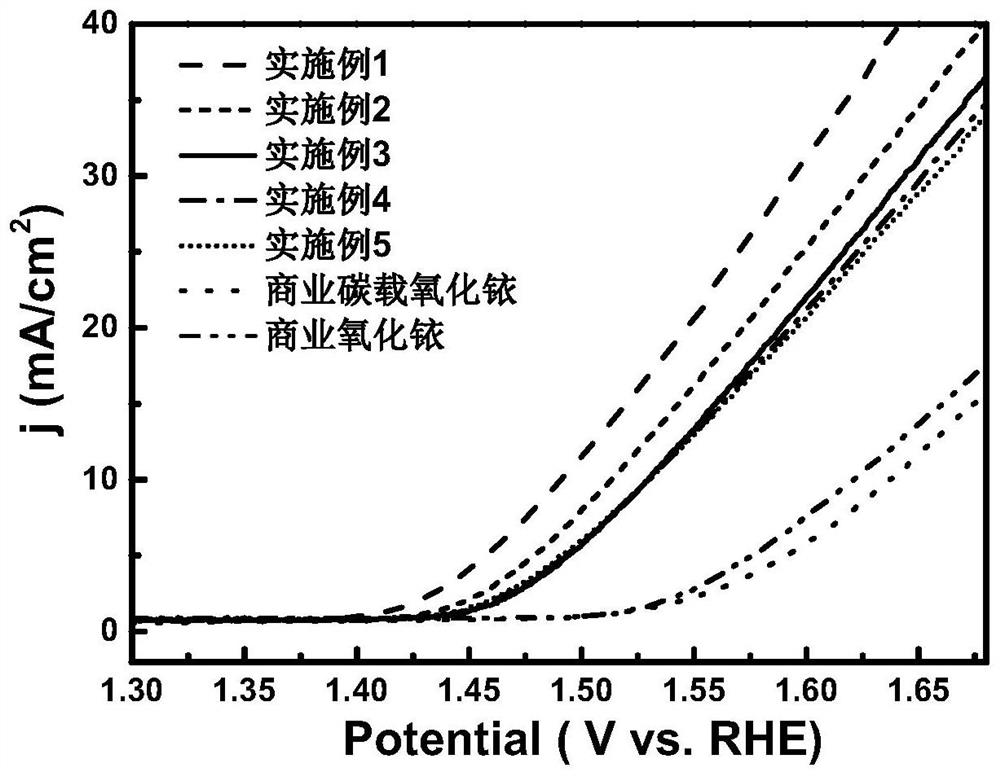

Embodiment 1

[0058] (1) dissolving zinc nitrate and cobalt nitrate in methanol, adding them to methanol containing 2-methylimidazole, stirring and mixing, washing and drying to obtain nitrogen-doped metal organic framework;

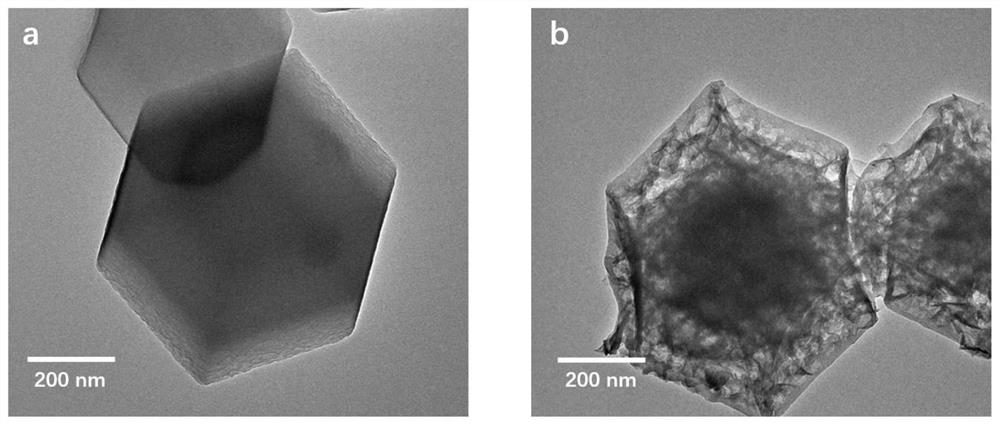

[0059] (2) Dissolve the composite pore-forming agent composed of nitrogen-doped metal-organic framework, ammonium chloride and sodium chloride in water, wherein the mass ratio of metal-organic framework and composite pore-forming agent is 1:5, ammonium chloride and chlorine The mass ratio of sodium chloride is 1:6, fully stirring and mixing at 90 °C, rotary evaporation, drying and grinding, and then sintering at 900 °C for 3 hours in a nitrogen atmosphere to obtain a carrier porous metal carbonitride material, wherein the nitrogen content is 12.8%, zinc content is 0% (Zn atom evaporates at high temperature), cobalt content is 2%, the porous metal nitrogen carbon material is first washed with ultrapure water, and then placed in a nitric acid aqueous solution of 60°C and...

Embodiment 2

[0063] (1) Ferric chloride and zinc chloride are dissolved in ethanol, and added to the ethanol containing dicyandiamide and trimesic acid (the mass ratio of the two is 8:2), stirred and mixed, and rotary evaporated and dried to obtain a mixed solution. Nitrogen metal organic framework;

[0064] (2) Dissolve the composite pore-forming agent composed of nitrogen-doped metal-organic framework, ammonium carbonate and sodium chloride in water, wherein the mass ratio of metal-organic framework and composite pore-forming agent is 1:3, and the mass ratio of ammonium carbonate and sodium chloride is 1:3. The ratio is 1:3, fully stirring and mixing at 60 ° C, rotary evaporation, drying and grinding, and sintering at 1100 ° C in an argon atmosphere for 2 hours to obtain a carrier porous metal nitrogen carbon material, wherein the nitrogen content is 11.5% , the iron content is 3%, the zinc content is 0%, the porous metal nitrogen carbon material is first washed with ultrapure water, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com