Porous biological filler for purifying polluted seawater as well as preparation method and application of porous biological filler

A biological filler and seawater purification technology, applied in the direction of water pollutants, chemical instruments and methods, applications, etc., can solve the problems of microbial growth and aggregation that are difficult to degrade, marine pollution, single filler components, etc., to improve the slow growth of microorganisms in water treatment and aggregation difficulties, increase the contact area with water body, and strengthen the effect of heterotrophic denitrification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

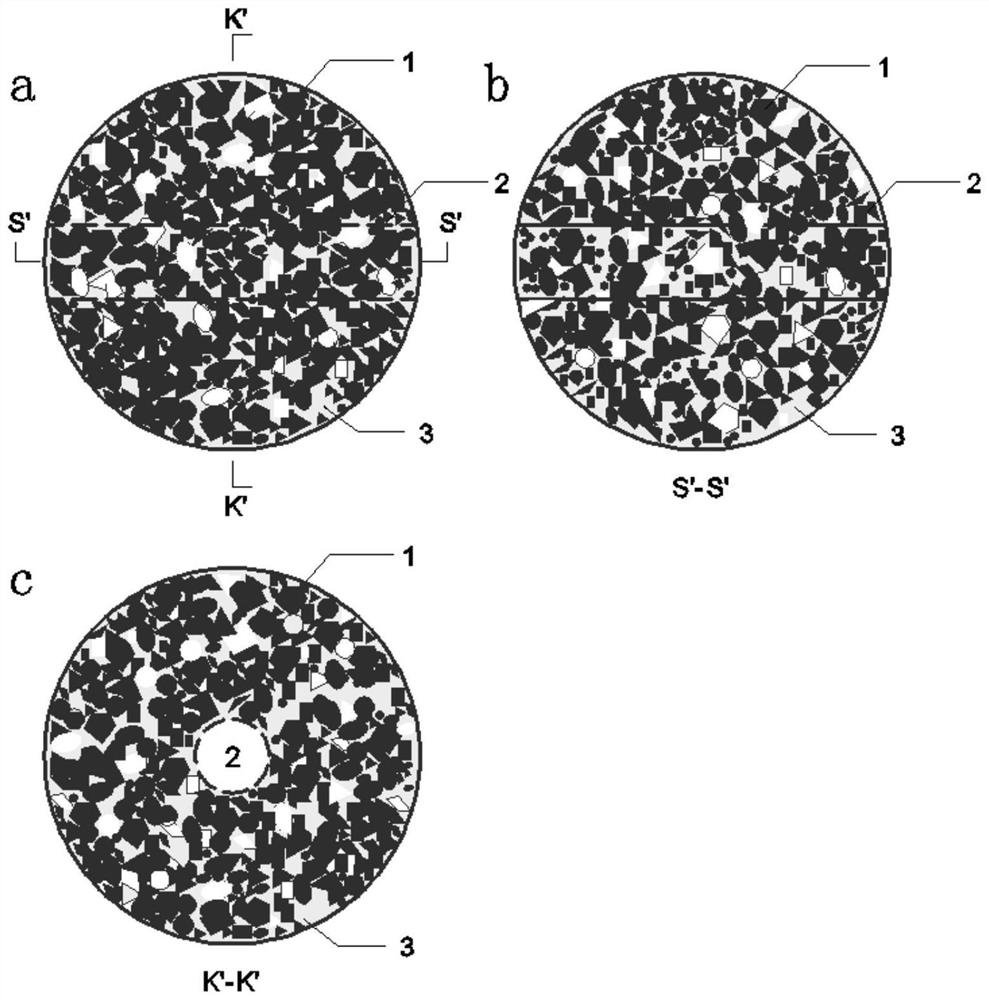

[0040] A preparation method of a porous biological filler for purification of polluted seawater, comprising the following steps:

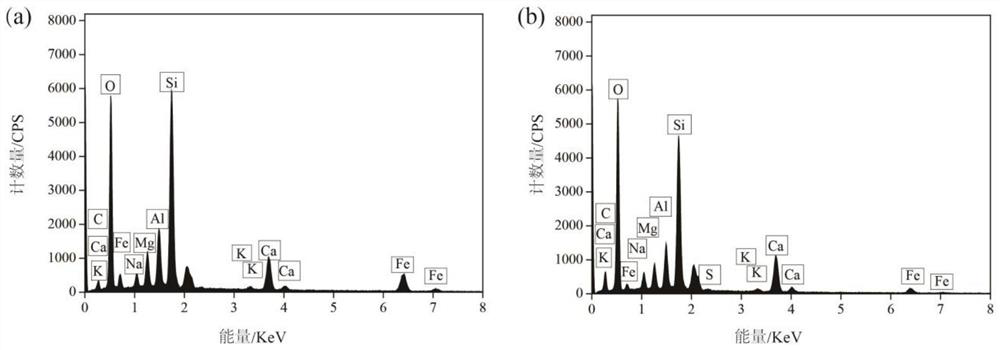

[0041] Step 1: Prepare materials and their weight percentages are: reduced iron powder 17.4%, activated carbon powder 4.3%, graphite powder 4.3%, quartz powder 17.2%, tourmaline powder 4.4%, diatomite 4.4%, zeolite powder 8.6%, volcanic stone powder 4.4%, medical stone powder 4.4%, ammonium bicarbonate 0.5%, sodium bentonite 30%; after mixing uniformly, an inorganic mixture is obtained.

[0042] Step 2: Disperse the graphene with a weight of 1% by weight of the inorganic mixture with a dispersant (sodium dodecyl sulfate) (wherein 1g of graphene is put into 0.07g of the dispersant, and the concentration is recommended not to exceed 2mg / mL when configuring the dispersion liquid, That is, 0.07g of dispersant is put into 35mL of distilled water) for subsequent use.

[0043] Step 3: The dispersed graphene and the tap water (chlorinated water) whose weigh...

Embodiment 2

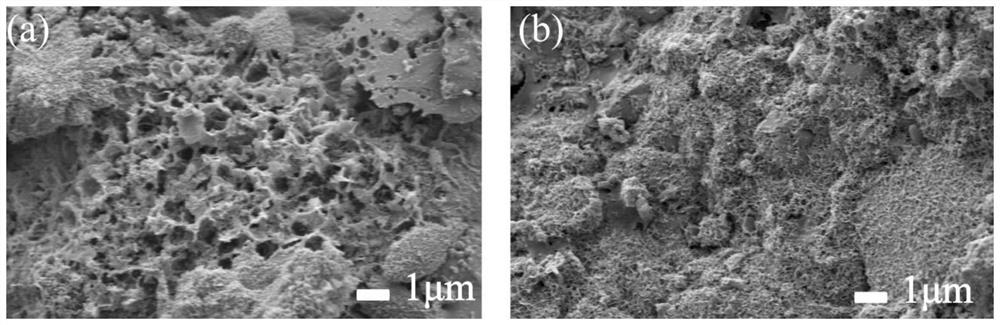

[0051] The porous biological filler prepared in Example 1 was filled into a cylindrical plexiglass column (10 cm in diameter, 70 cm in height; the reactor was completely covered with tin foil), and the bottom layer of the cylindrical column was filled with about 5 cm of gravel filler as a supporting layer, and then filled with 50cm porous biological packing; a water distribution tank with a working volume of 10L was used. The temperature of the water distribution tank was controlled by an electric heater at a temperature of 25 °C, and the influent water was controlled by a peristaltic pump at the same flow rate. For waste water, the water level was adjusted to 5 cm above the surface of the filler, and the cylindrical reactor was continuously operated at 25°C for 2 months to a stable hanging period, and then the pollutant removal experiment was started.

[0052] Further, glucose, potassium nitrate, ammonium chloride, and potassium dihydrogen phosphate were added to the tap water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com