Growth method of gallium oxide bulk single crystal with low dislocation density

A growth method, gallium oxide technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of high melting point, difficult industrialization, high production cost, etc., achieve low dislocation density, low production cost, crystal The effect of less defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

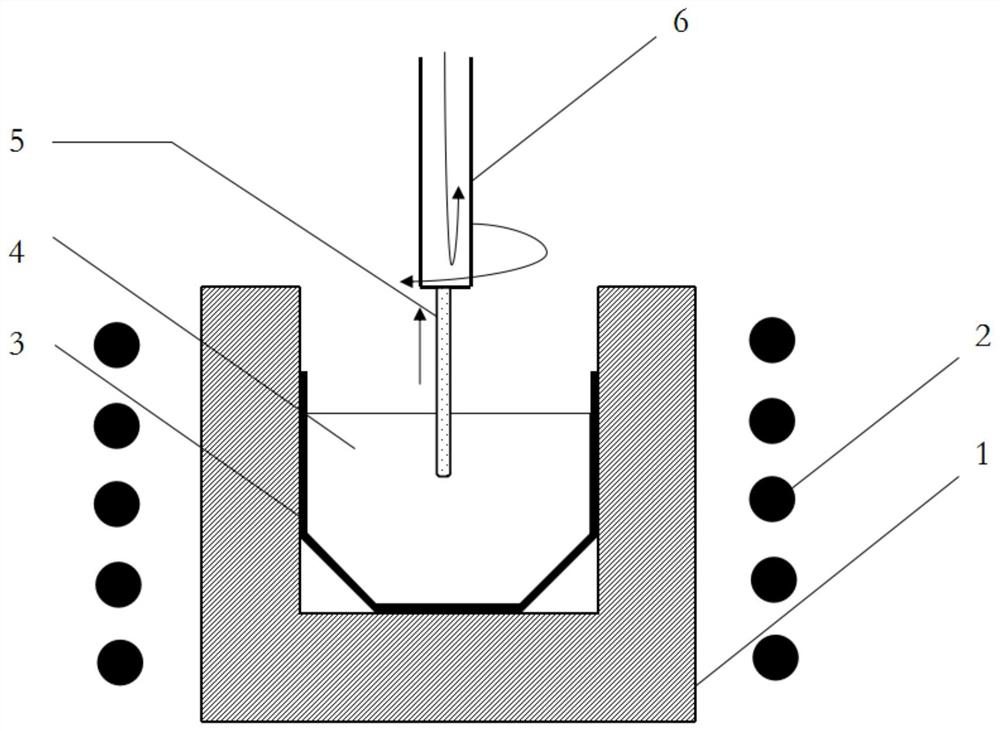

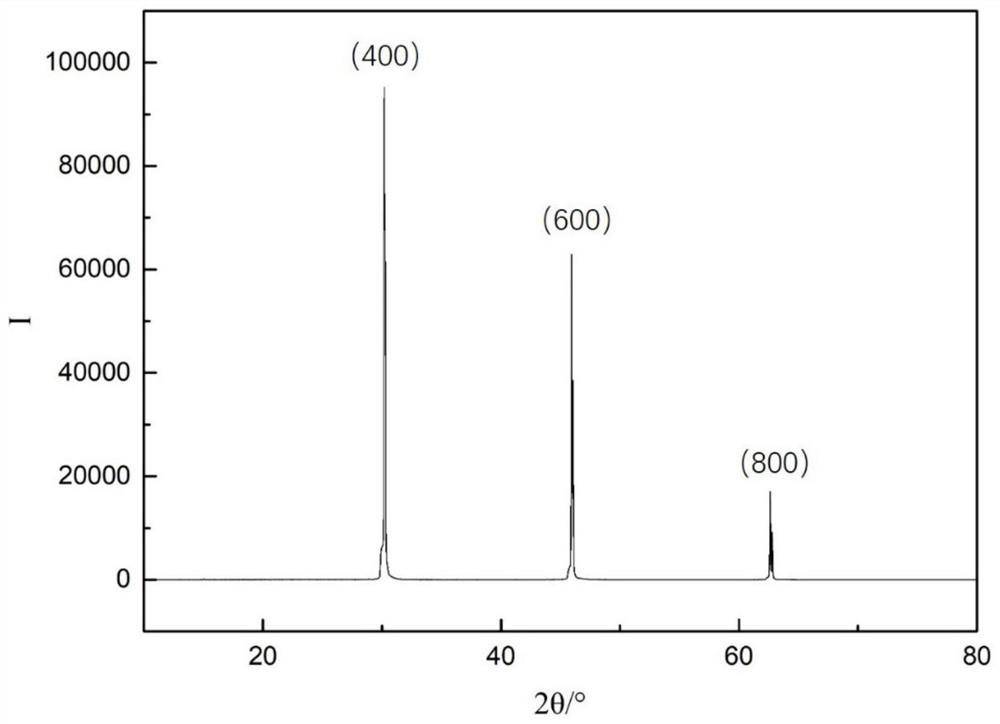

[0043] see figure 1 and figure 2 , the present invention is a low dislocation density gallium oxide bulk single crystal growth method, comprising the following steps: first wipe with a clean cloth alcohol, then use an industrial vacuum cleaner to clean the furnace, insulation layer and crucible, etc., and then in a clean room with a purity greater than 99.99% 5N grade gallium oxide raw material is loaded into the crucible, the crucible is placed in the furnace of the single crystal furnace, and the β-Ga in the [010] direction is placed in the crucible. 2 O 3 The crystal seed is loaded on the seed rod, and the seed rod is centered. After the furnace is finally closed, the vacuum is evacuated to 1×10 -3 Below Pa, recharge with 1 atmosphere of CO 2 The gas is used as a protective gas to heat the crucible. After the gallium oxide raw material is completely melted, the high temperature melt state is maintained for 5 hours. The thickness of liquid flow, the size of the floating...

Embodiment 2

[0045] see figure 1 , the present invention is a low dislocation density gallium oxide bulk single crystal growth method, comprising the following steps: first wipe with a clean cloth alcohol, then use an industrial vacuum cleaner to clean the furnace, insulation layer and crucible, etc., and then in a clean room with a purity greater than 99.99% 5N grade gallium oxide raw material is loaded into the crucible, the crucible is placed in the furnace of the single crystal furnace, and the β-Ga in the [010] direction is placed in the crucible. 2 O 3 The crystal seed is loaded on the seed rod, and the seed rod is centered. After the furnace is finally closed, the vacuum is evacuated until the vacuum degree is 1×10. -3 Below Pa, recharge with 1 atmosphere of CO 2 The gas is used as a protective gas to heat the crucible. After the gallium oxide raw material is completely melted, the high temperature melt state is maintained for 3 hours, and the seed crystal is lowered to 10mm above...

Embodiment 3

[0047] see figure 1 , the present invention is a low dislocation density gallium oxide bulk single crystal growth method, comprising the following steps: first wipe with a clean cloth alcohol, then use an industrial vacuum cleaner to clean the furnace, insulation layer and crucible, etc., and then in a clean room with a purity greater than 99.99% 5N grade gallium oxide raw material is loaded into the crucible, the crucible is placed in the furnace of the single crystal furnace, and the β-Ga in the [010] direction is placed in the crucible. 2 O 3 The crystal seed is loaded on the seed rod, and the seed rod is centered. After the furnace is finally closed, the vacuum is evacuated to 1×10 -3 Below Pa, recharge with 1 atmosphere of CO 2 The gas is used as a protective gas to heat the crucible. After the gallium oxide raw material is completely melted, the high temperature melt state is maintained for 3 hours, and the seed crystal is lowered to 10mm above the liquid level, and ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com