Nitrogen and phosphorus co-doped vanadium oxide/carbon self-supporting electrode material and preparation method and application thereof

A self-supporting electrode, vanadium oxide technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as difficulty in regulating the content of oxygen vacancies, and difficulty in substantially improving the electrochemical performance of electrodes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

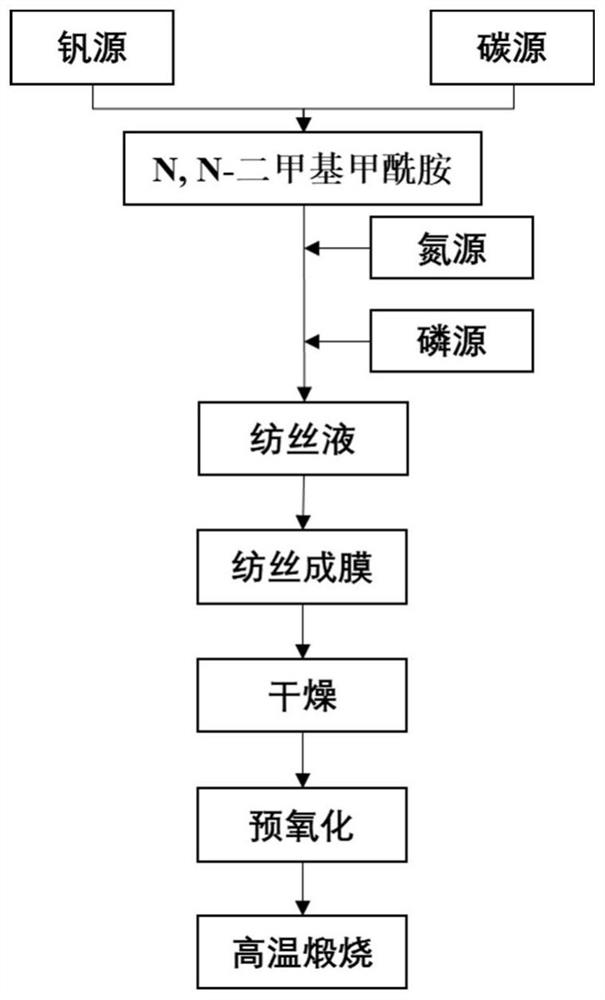

[0031] Preparation of spinning solution: add 0.6g vanadium acetylacetonate and 0.4g polyacrylonitrile to the organic solution dissolved in 1g N,N-dimethylformamide, stir at 50°C under constant temperature magnetic force for 6h, and the stirring speed is 500r / min, to prepare a homogeneous solution. Subsequently, keeping the temperature and stirring speed unchanged, 0.2 g of melamine and 0.1 g of melamine phosphate were added to the above solution every 6 h to obtain a uniform spinning solution, and the order of addition of melamine and melamine phosphate was not limited.

[0032] Electrospinning: The above spinning solution is transferred into a needle tube for spinning to prepare a film. Among them, the working distance is 17cm, the humidity is 17%, the temperature is 32°C, the positive voltage is 16kV, the negative voltage is -0.05kV, the drum speed is 250r / min, and the spinning needle type is 19G.

[0033] Removal of organic solution: dry in a drying oven at 60°C for 6 h t...

Embodiment 2

[0043] Preparation of spinning solution: add 0.6g vanadium acetylacetonate and 0.4g polyacrylonitrile to the organic solution dissolved in 1g N,N-dimethylformamide, stir at 50°C under constant temperature magnetic force for 6h, and the stirring speed is 500r / min, to prepare a homogeneous solution. Subsequently, keeping the temperature and stirring speed unchanged, 0.2 g of melamine and 0.1 g of melamine phosphate were added to the above solution every 6 h to obtain a uniform spinning solution, and the order of addition of melamine and melamine phosphate was not limited.

[0044] Electrospinning: The above spinning solution is transferred into a needle tube for spinning to prepare a film. Among them, the working distance is 17cm, the humidity is 17%, the temperature is 32°C, the positive voltage is 16kV, the negative voltage is -0.05kV, the drum speed is 250r / min, and the spinning needle type is 19G.

[0045] Removal of organic solution: dry in a drying oven at 60°C for 6 h t...

Embodiment 3

[0049] Preparation of spinning solution: add 0.6g vanadium acetylacetonate and 0.4g polyacrylonitrile to the organic solution dissolved in 1g N,N-dimethylformamide, stir at 50°C under constant temperature magnetic force for 6h, and the stirring speed is 500r / min, to prepare a homogeneous solution. Subsequently, keeping the temperature and stirring speed unchanged, 0.2 g of melamine and 0.12 g of melamine phosphate were added to the above solution every 6 hours to obtain a uniform spinning solution, and the order of addition of melamine and melamine phosphate was not limited.

[0050] Electrospinning: The above spinning solution is transferred into a needle tube for spinning to prepare a film. Among them, the working distance is 17cm, the humidity is 17%, the temperature is 32°C, the positive voltage is 16kV, the negative voltage is -0.05kV, the drum speed is 250r / min, and the spinning needle type is 19G.

[0051] Removal of organic solution: dry in a drying oven at 60°C for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com