Method for testing swelling degree of solid powdery polymer composite material

A technology of solid powder and composite materials, which is applied in the direction of absorption and weighing of substances, which can solve the problems of unclear solvent types, test procedures and methods, poor applicability, and inability to apply powder PI swelling degree test, etc., to improve the test efficiency. , Good impregnation degree, stable test data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

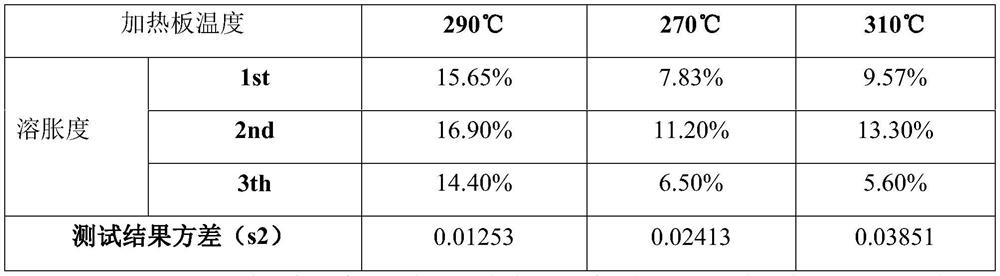

Embodiment 1

[0026] (1) The temperature of the upper and lower heating plates of the pressure forming machine is set to 290 ° C, the mold is placed in the predetermined position of the pressure forming machine, and the heater is turned on to preheat for 30 minutes;

[0027] (2) Evenly coat the silicone mold release agent on the surface of the mold, weigh 38.5g of the solid powder sample of polymer composite material whose main component is more than 95% polyamide, place it on the lower mold, put it on the mold after leveling, and adjust the pressure Press for 4Mpa, release the pressure within 40s, and let it stand for 8min;

[0028] (3) Transfer the mold to a cold press, press with a pressure of 14Mpa, cool down to 90°C, and take out the tablet molding sample;

[0029] (4) The obtained 80*80mm sample sheet is cut into 10*10mm square slices, and smoothed with an abrasive tool, and the slice weight is W1=4.6g;

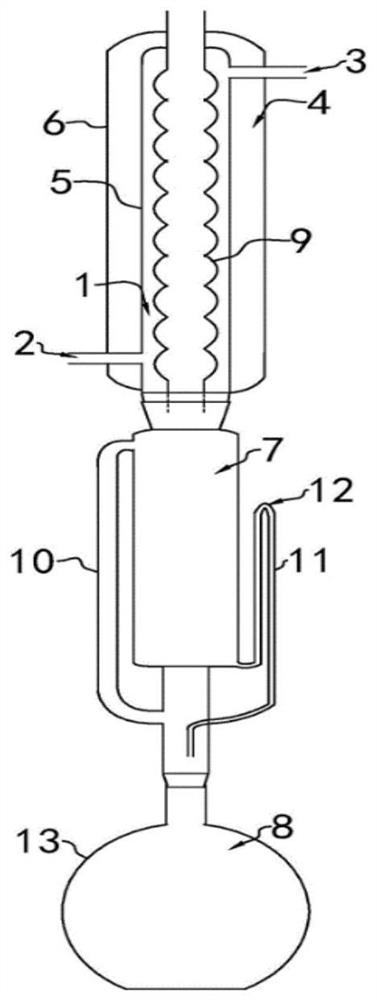

[0030] (5) wrap the slices in a cloth bag, put them into a Soxhlet extractor, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com