Hybrid electrolytic capacitor and method of manufacturing same

An electrolytic capacitor, a hybrid technology, applied in the direction of electrolytic capacitors, liquid electrolytic capacitors, solid electrolytic capacitors, etc., can solve the problems of insufficient evaluation and increased leakage current of solid electrolytic capacitors, and achieve low ESR, high electrostatic capacitance, high temperature The effect of durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

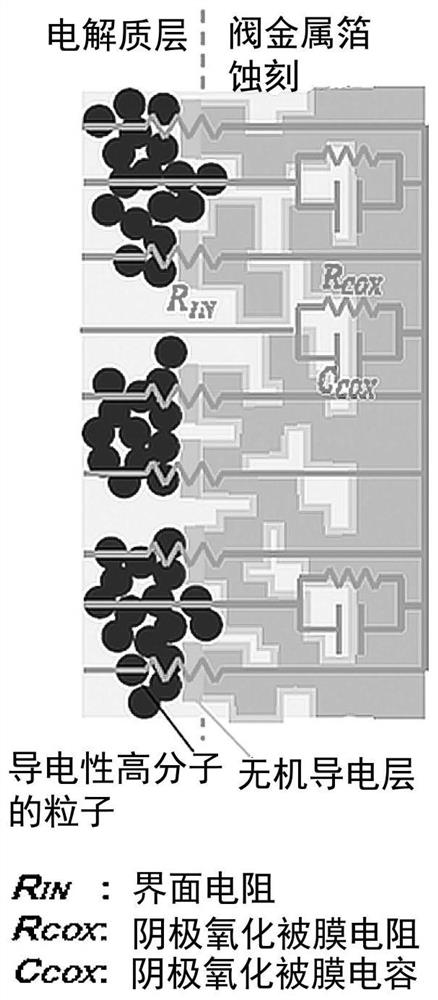

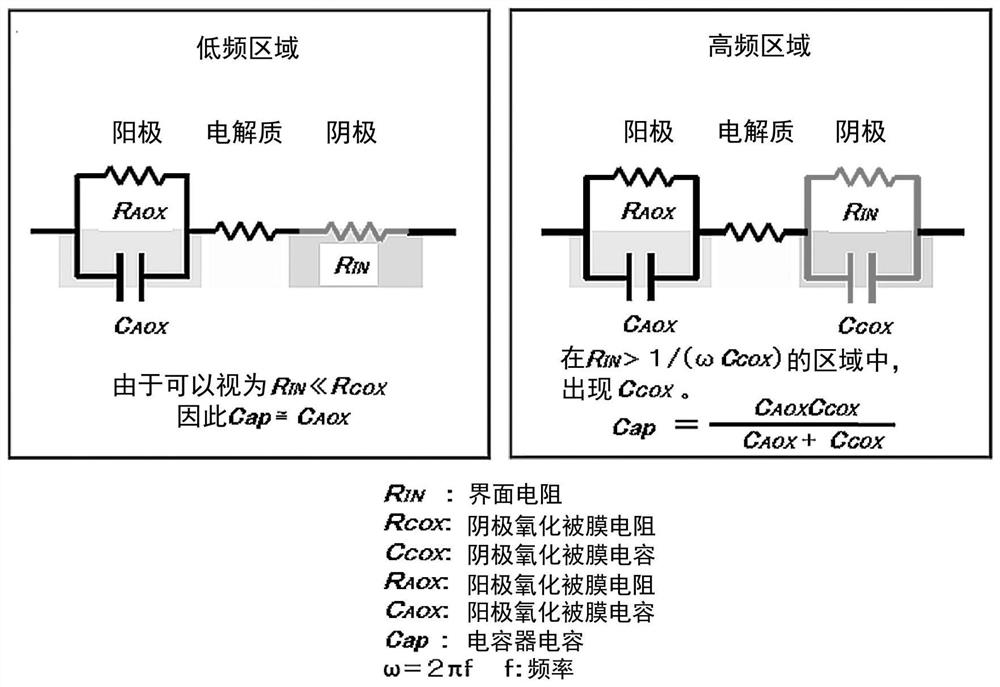

[0083] The dispersion liquid is prepared, for example, by adding a monomer, a dopant-releasing acid or a salt thereof, and an oxidizing agent to water as a dispersion medium, stirring until the completion of chemical oxidative polymerization, and then using ultrafiltration, cationic The oxidizing agent and residual monomer are removed by purification methods such as exchange and anion exchange, and then, if necessary, dispersion treatment such as ultrasonic dispersion treatment, high-speed fluid dispersion treatment, and high-pressure dispersion treatment is applied. As the monomer, the monomer having a π-conjugated double bond given above for forming the organic conductive layer can be used, and a monomer selected from thiophenes having substituents at the 3-position and the 4-position can be preferably used. Substituents at the 3- and 4-positions of the thiophene ring may form a ring together with the carbons at the 3- and 4-positions. In particular, 3,4-(ethylenedioxythioph...

Embodiment 1

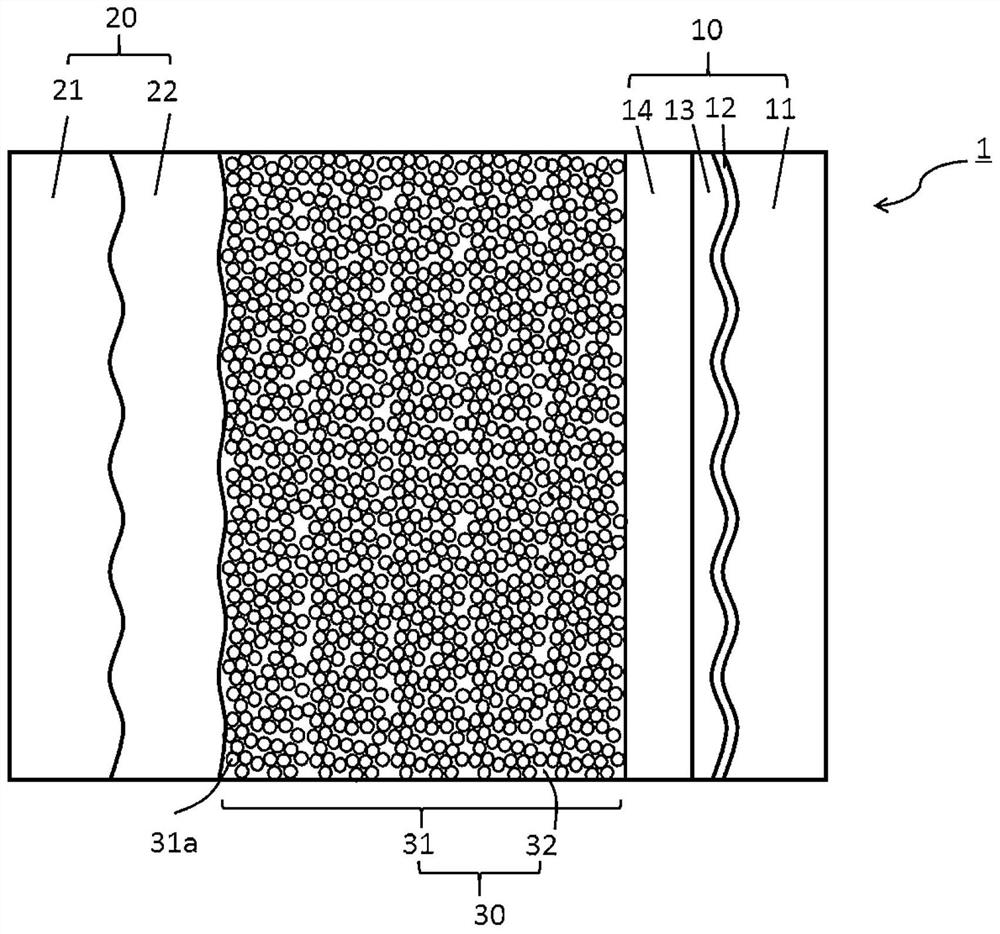

[0092] As a cathode substrate for obtaining a cathode, an aluminum foil in which a sponge-like pit was formed was used. A chemical conversion treatment was applied to the aluminum foil using an aqueous solution of ammonium dihydrogen phosphate as a chemical conversion solution, and a chemical conversion voltage of 5.0 V was formed on the surface of the aluminum foil. fs The chemical oxide film (oxide layer). Then, a vapor-deposited film containing titanium carbide is formed on the surface of the chemical conversion oxide film by arc ion plating to obtain a support having a vapor-deposited titanium carbide film (inorganic conductive layer).

[0093] Into a glass container, 50 mL of distilled water was introduced and heated to 40°C. To this liquid was added 0.021M 3,4-(ethylenedioxythiophene) (hereafter, 3,4-(ethylenedioxythiophene) is represented as "EDOT", and poly(3,4-(ethylenedioxythiophene) was Ethylenedioxythiophene)) is represented by PEDOT.) and 0.08M ammonium boronate...

Embodiment 2

[0100] Using the polymerization solution for electrolytic polymerization used in Example 1, at 0.1 mA / cm 2 Galvanostatic electropolymerization was carried out for 2 minutes under the conditions of / cm 3 The density of , except this point, repeat the procedure of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com