Medicine controlled functional cement with calcium phosphate being as framework and its preparation method

A calcium phosphate bone cement, drug controlled release technology, applied in medical science, prosthesis, surgery, etc., can solve the problems of easy to cause osteolysis, long-term foreign body existence, material brittleness, etc., to promote rapid healing, accelerated degradation, Excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Weigh 50 mg of ethyl cellulose, dissolve it in acetone under water bath conditions, after it is completely dissolved, add 100 mg of tobramycin, stir evenly, pour 2 g of liquid paraffin containing 8 ml of Span 80, and circulate water at 60 ° C Constant temperature, stirring, suction filtration, washing, and drying to prepare tobramycin microcapsules.

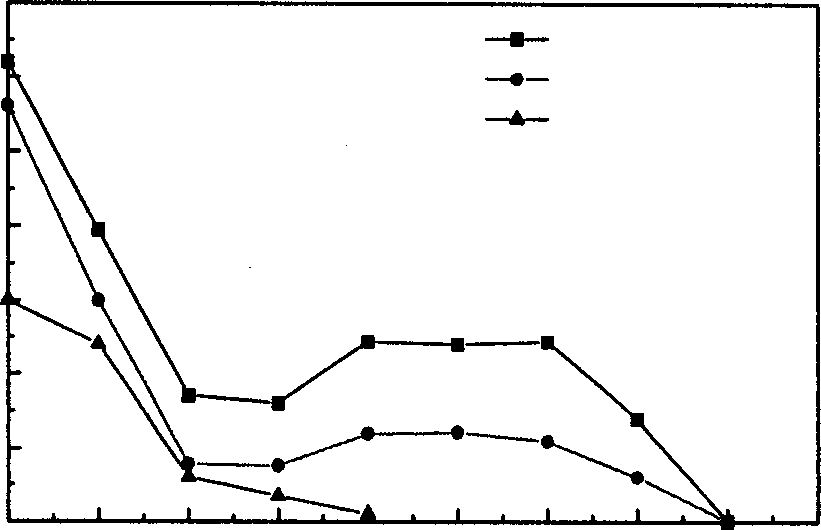

[0034] Weigh 0.1g of pore-forming agent (200~350μm), calcium hydrogen phosphate, tetracalcium phosphate, and 3g of CPC powder with a particle size less than 20μm, and add the prepared tobramycin microcapsules at the same time. Disperse evenly in the bowl, add 1.2g of normal saline, use a dental knife to mix and evenly form a mud mass, place it in a 37°C, 100% humidity environment for 48 hours, and then soak it in a simulated buffer solution, and take samples at appropriate time intervals. The concentration of tobramycin was determined by ultraviolet spectrophotometry, which indicated that the degree of drug-loaded porous c...

Embodiment 2

[0036] Weigh 50 mg of ethyl cellulose, dissolve it in acetone under water bath conditions, after it is completely dissolved, add 100 mg of naproxen sodium, stir evenly, pour 2 g of liquid paraffin containing 8 ml of Span 80, and circulate water at 60 ° C Constant temperature, stirring, suction filtration, washing, and drying to prepare naproxen sodium microcapsules. Weigh 0.1g of pore-forming agent (200~350μm), calcium hydrogen phosphate, tetracalcium phosphate, and 3g of CPC powder whose particle size is less than 20μm, and add the prepared naproxen sodium microcapsules at the same time. Disperse evenly in the bowl, add 1.2g of normal saline, use a dental knife to mix and evenly form a mud mass, place it in a 37°C, 100% humidity environment for 48 hours, and then soak it in a simulated buffer solution, and take samples at appropriate time intervals. The concentration of naproxen sodium was determined by ultraviolet spectrophotometry, which showed that the degree of drug-loade...

Embodiment 3

[0038] Weigh 50 mg of ethyl cellulose, dissolve it in acetone under the condition of water bath, after it is completely dissolved, add 100 mg of rifampicin, stir evenly, pour 2 g of liquid paraffin containing 8 ml of Span 80, and circulate water at 60°C to keep the temperature constant , stirring, suction filtration, washing, and drying to obtain rifampicin microcapsules. Weigh 0.1g of pore-forming agent (200~350μm), calcium hydrogen phosphate, tetracalcium phosphate, and 3g of CPC powder with a particle size of less than 20μm, and add the prepared rifampicin microcapsules at the same time. Disperse evenly in medium, add 1.2g of normal saline, use a dental knife to mix and evenly form a mud mass, place it in a 37°C, 100% humidity environment for 48 hours, and then soak it in a simulated buffer solution, take samples at appropriate time intervals, and use ultraviolet light The concentration of rifampicin was determined by spectrophotometry, which indicated that the release of d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com