Preparing method for loaded titania catalyst of ester interchange synthetic phenyl ester oxalate

A technology of titanium dioxide and phenyl oxalate, which is applied in the direction of catalyst activation/preparation, preparation of organic compounds, physical/chemical process catalysts, etc., can solve problems such as catalyst preparation methods not mentioned, and save separation process and equipment, transformation The efficiency and selectivity of products are improved, and the effect of no pollution to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

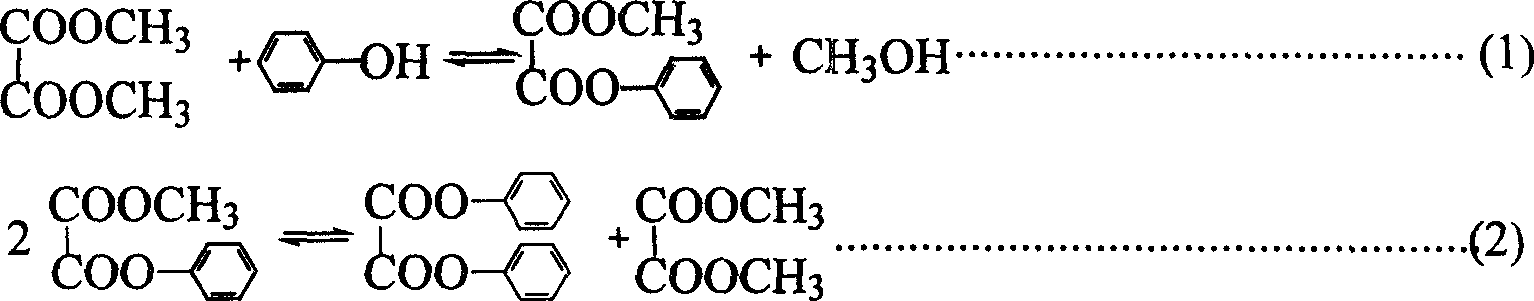

Method used

Image

Examples

Embodiment 1

[0018] [Example 1] Preparation and Activity Investigation of Supported Titanium Oxide Catalyst

[0019] The present invention prepares phenol and dimethyl oxalate transesterification and synthesizes phenyl oxalate with supported titanium oxide catalyst implementation investigation. Dry the silica gel carrier particles in a drying oven at 120° C. for later use. Weigh 0.86 g of tetrabutyl titanate and dissolve it in 80 ml of absolute ethanol, stir in nitrogen flow at room temperature for 0.5 h, put 20 g of pretreated silica gel carrier with a particle size of 80 Å, stir well for 2 h, slowly drop Add an ethanol solution containing 0.4 g of deionized water. Put the fully stirred mixture at room temperature for 24-72 hours in a nitrogen stream to obtain a solid powder, dry the solid at 60-200°C for 5 hours, then put it into a muffle furnace and bake it at 550°C for 5 hours , that is, a supported titania catalyst with a titania loading of 1 wt % was prepared.

[0020] In the pres...

Embodiment 2-8

[0022] Changing the Supported Metal Oxide Catalyst TiO 2 / SiO 2 The loaded amount of titanium oxide in the middle is respectively 4%, 8%, 10%, 12%, 14%, 16%, 18%, and under the situation that other conditions are identical with embodiment 1, carry out transesterification reaction, form respectively Embodiment 2-8, investigate reaction result.

[0023] Table 1: TiO 2 / SiO 2 Series of catalysts catalyzed transesterification reaction results (weight percentage)

Embodiment

[0026] Amount, % Conversion % Anisole MPO DPO MPO DPO

[0027] 1 1 45.9 0.6 79.0 19.7 36.3 9.0

[0028] 2 4 46.5 0.8 77.4 21.5 36.0 10.0

[0029] 3 8 52.5 0.9 75.7 23.0 39.7 12.1

[0030] 4 10 62.3 0.9 73.6 23.9 45.9 14.9

[0031] 5 12 66.3 0.4 71.9 27.3 47.7 18.1

[0032] 6 14 63.9 0.4 73.1 26.2 46.7 16.7

[0033] 7 16 60.3 0.6 76.7 22.4 46.3 13.5

[0034] 8 18 53.8 0.4 76.2 22.9 41.0 12.3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com