Ni-S active cathode for hydrogen evolution with gradient structure and method for preparing same

A gradient structure, hydrogen evolution cathode technology, applied in electrodes, electrolytic inorganic material coatings, electrolytic coatings, etc., can solve problems such as easy peeling, large internal stress in the coating, and decreased activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Step 1: Add NiSO 4 ·7H 2 O, NiCl 2 ·6H 2 O, H 3 BO 3 Compounds were dissolved in deionized water and formulated to contain 200gdm -1 NiSO 4 ·7H 2 O. 35gdm -1 NiCl 2 ·6H 2 O. 25gdm -1 h 3 BO 3 Adjust the pH value of the electrolyte to 4.2; take the surface-cleaned ordinary iron plate as the cathode, and the nickel plate as the anode, add the above-mentioned electrolyte into the electrolytic cell, heat it to 40°C, and put it at 25mAcm -2 Constant current deposition for 25min.

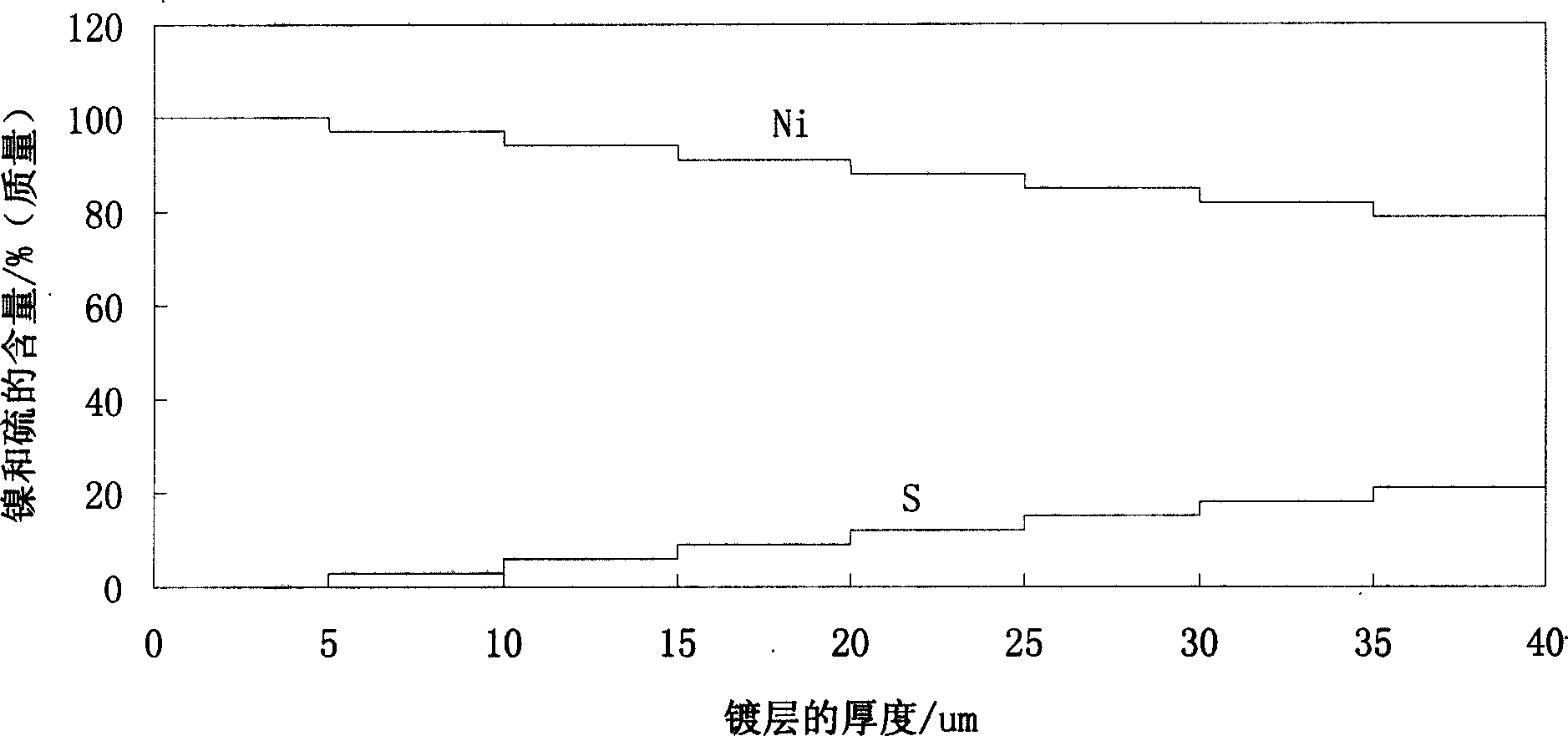

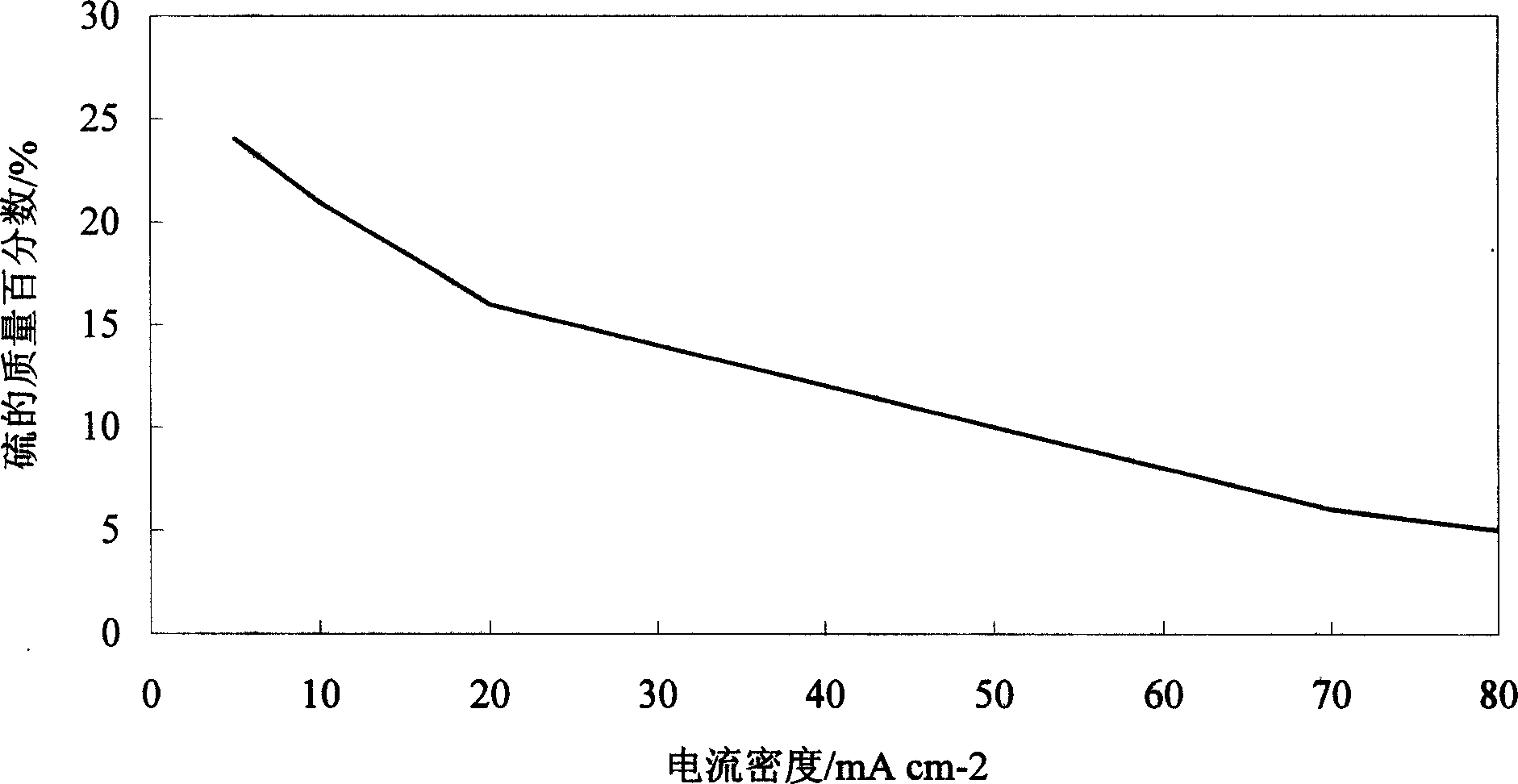

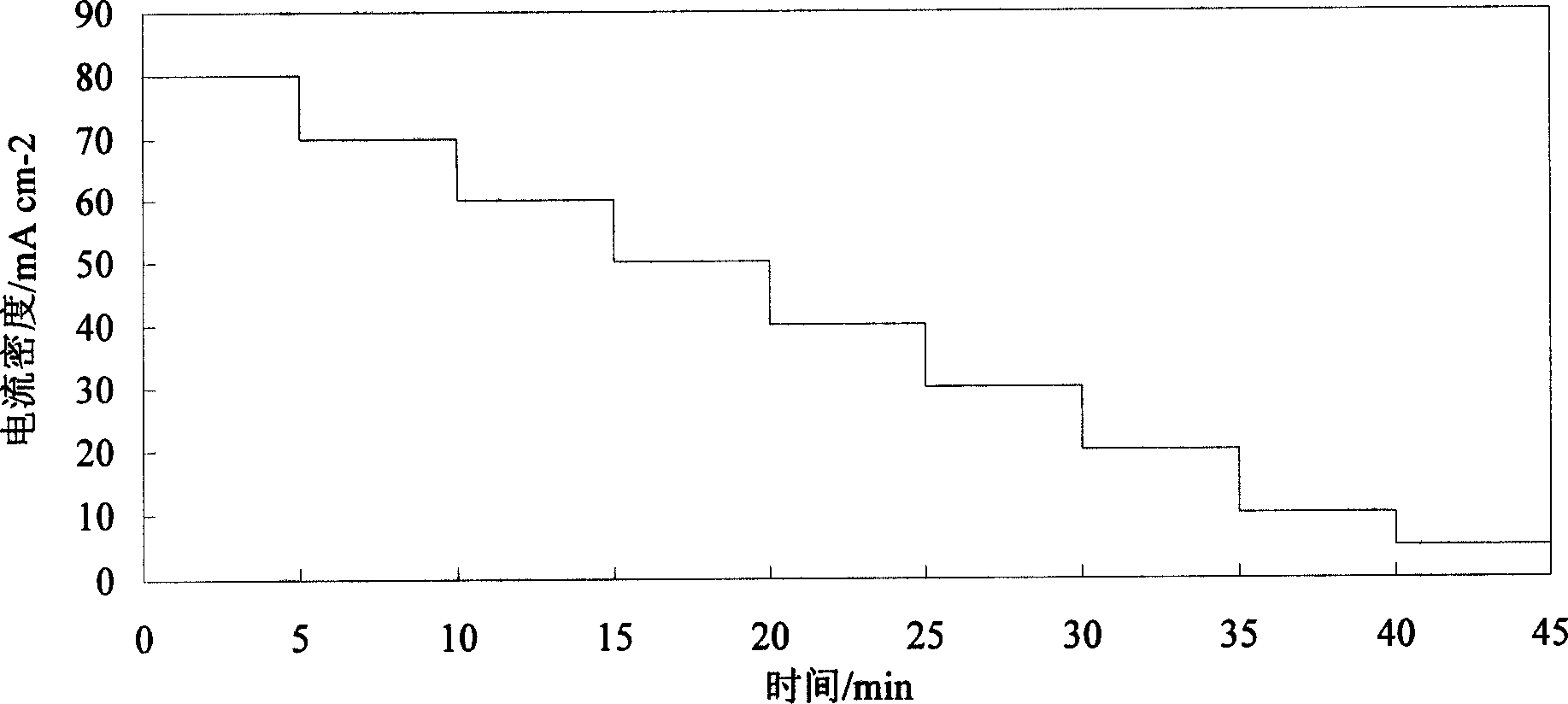

[0033] Step 2: Add NiSO 4 ·7H 2 O, NiCl 2 ·6H 2 O, H 3 BO 3 , Thiuria, sodium thiosulfate and other substances are dissolved in deionized water and configured to contain 0.7M NiSO 4 ·7H 2 O, 0.1M NiCl 2 ·6H 2 O, 0.4M H 3 BO 3 , 0.6M thiourea and 0.05M sodium thiosulfate, adjust the pH value of the electrolyte to 4.5, use the ordinary iron sheet with metallic nickel deposited on the surface prepared in step 1 as the cathode, and the nickel plate as the anode, add the abov...

Embodiment 2

[0035] Step 1: Add NiSO 4 ·7H 2 O, NiCl 2 ·6H 2 O, H 3 BO 3 Compounds were dissolved in deionized water and formulated to contain 225gdm -1 NiSO 4 ·7H 2 O. 30gdm -1 NiCl 2 ·6H 2 O. 30gdm -1 h 3 BO 3 Electrolyte, adjust the pH value of the electrolyte to 3.8. Use the ordinary barbed wire with clean surface as the cathode, foam nickel as the anode, add the above-mentioned electrolyte in the electrolytic cell, heat to 50°C, -2 Constant current deposition for 20min.

[0036] Step 2: Add NiSO 4 ·7H 2 O, NiCl 2 ·6H 2 O, H 3 BO 3 , sulfur urine and other substances dissolved in deionized water, configured to contain 0.8M NiSO 4 ·7H 2 O, 0.1M NiCl 2 ·6H 2 O, 0.5M H 3 BO 3 , 0.9M sulfur urine, adjust the pH value of the electrolyte to 4.2. The ordinary barbed wire with metal nickel deposited on the surface prepared in step 1 is used as the cathode, and the foamed nickel is used as the anode. Add the above-mentioned electrolyte in the electrolytic cell and ...

Embodiment 3

[0038] Step 1: Add NiSO 4 ·7H 2 O, NiCl 2 ·6H 2 O, H 3 BO 3 The compound is dissolved in deionized water and formulated to contain 210gdm -1 NiSO 4 ·7H 2 O. 50gdm -1 NiCl 2 ·6H 2 O. 20gdm -1 h 3 BO 3 Electrolyte, adjust the pH value of the electrolyte to 5. Use the surface-cleaned ordinary iron sheet as the cathode, and the nickel plate as the anode, add the above-mentioned electrolyte solution into the electrolytic cell, heat it to 45°C, and -2 Constant current deposition for 20min.

[0039] Step 2: Add NiSO 4 ·7H 2 O, NiCl 2 ·6H 2 O, H 3 BO 3 , Thiuria, sodium thiosulfate and other substances are dissolved in deionized water and prepared to contain 0.6M NiSO 4 ·7H 2 O, 0.2M NiCl 2 ·6H 2 O, 0.3M H 3 BO 3 , 0.3M thiourea and 0.2M sodium thiosulfate to adjust the pH value of the electrolyte to 3. The ordinary iron sheet prepared in step 1 with metal nickel deposited on its surface is used as the cathode, and the nickel plate is used as the anode. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com