Modified alcohol-barrier proton exchange film based on hydrophilic area surface and its production

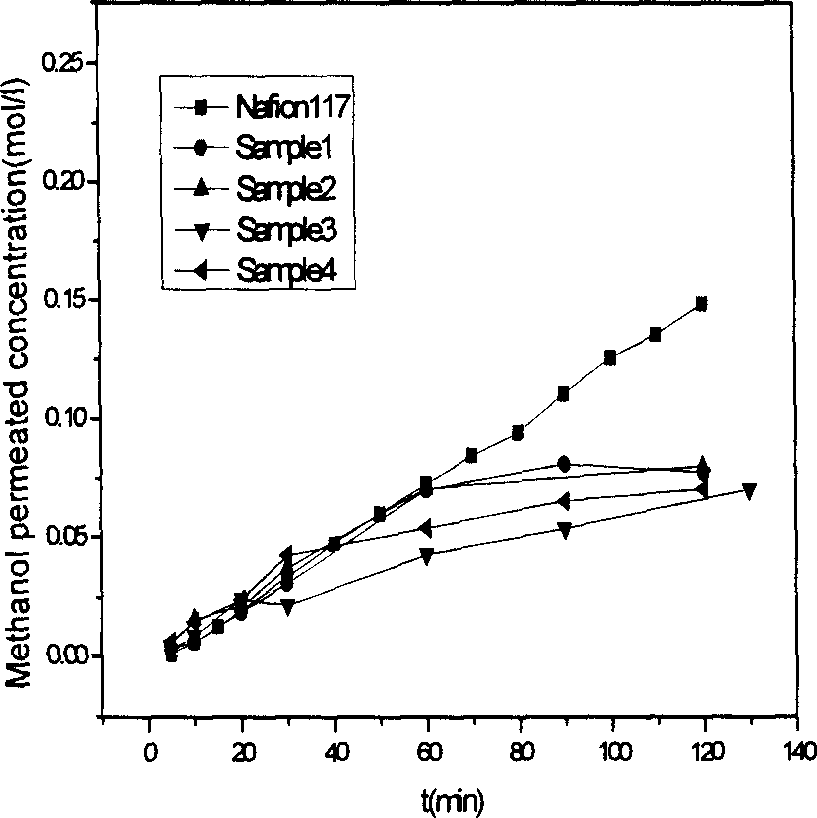

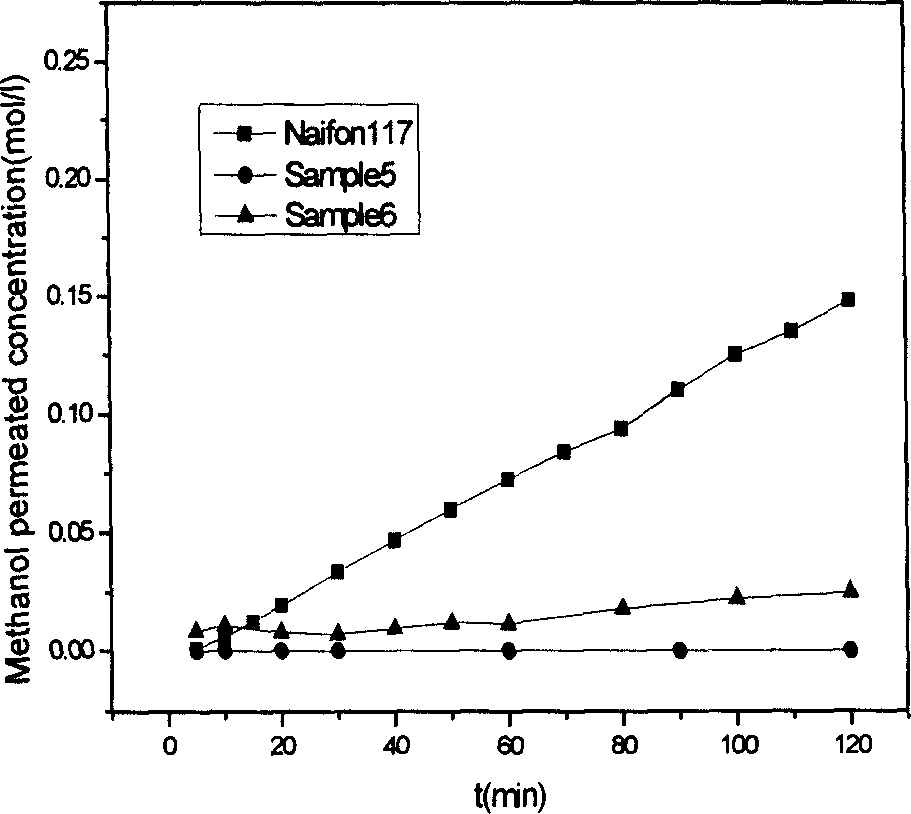

A technology of surface modification and proton exchange, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., to achieve good battery performance, reduce methanol permeation, and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

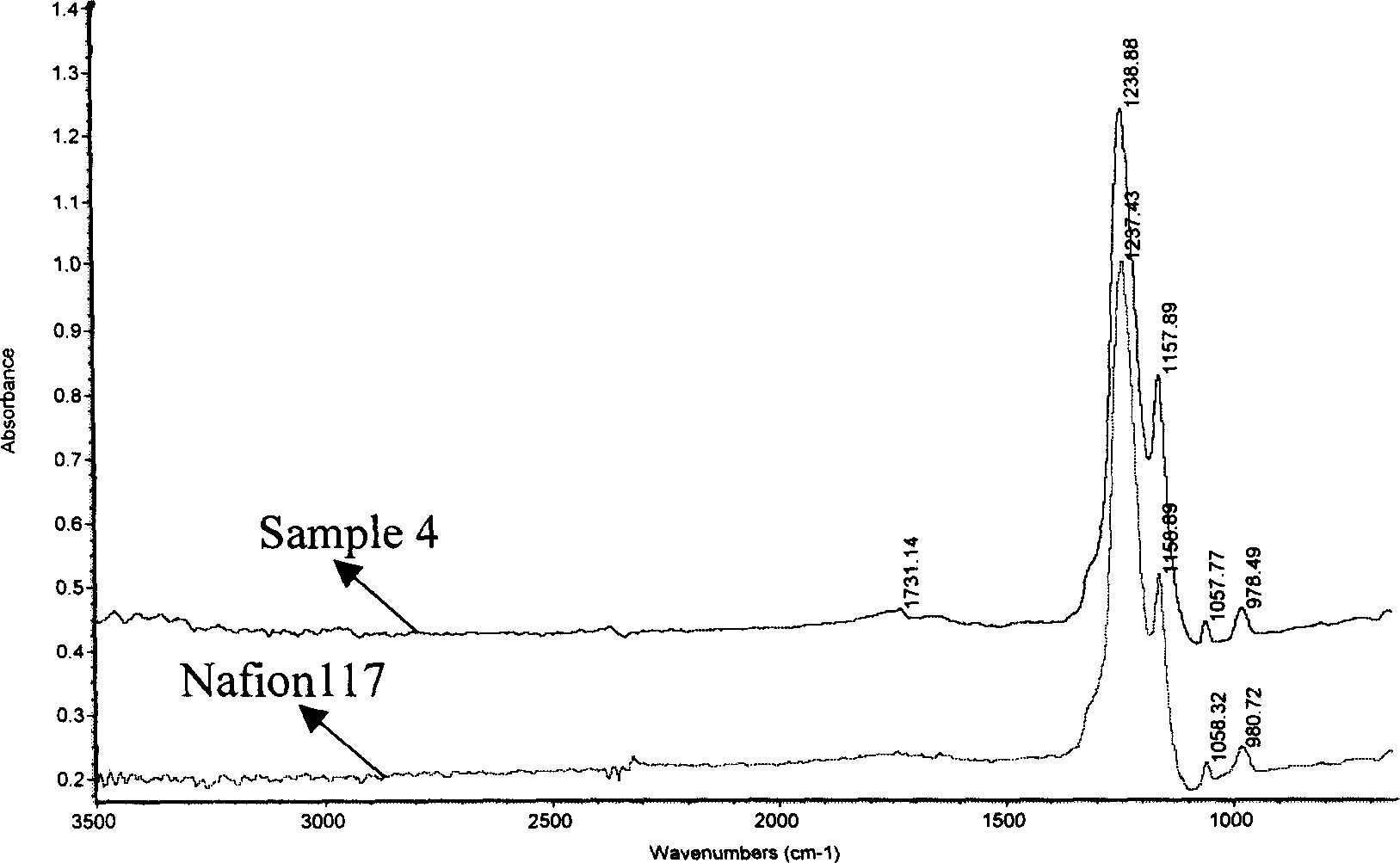

Method used

Image

Examples

Embodiment 1

[0022] 1) Place 4cm×4cm Nafion-117 membrane in 3%H 2 o 2 , 0.5mol / lH 2 SO 4 1. Treat in deionized water at 60°C for 1 hour, dry in a vacuum oven at 60°C for 24 hours, weigh, take it out, and place it in deionized water to fully immerse and hydrate for more than 24 hours.

[0023] 2) Prepare a 1:6 mixed solution of tetraethoxyn-silane and methanol, put the fully hydrated Nafion117 membrane in step 1) into the organosilane solution for 1 min, take it out, wash with methanol to remove the residual silane solution on the membrane surface , transfer the film to a vacuum drying oven at 80°C for complete reaction and dry it for more than 24 hours and weigh it. The surface functional group is hydroxyl, and the inorganic composite is a nano-scale silicon oxide network structure. The amount of silicon oxide is 4.0 % of the composite film.

Embodiment 2

[0025] 1) Place 4cm×4cm Nafion-117 membrane in 4%H 2 o 2 , 0.8mol / l H 2 SO 4 1. Treat in deionized water at 70°C for 1h, dry in a vacuum oven at 70°C for 24h, weigh, make a 1:1 mixed solution of methanol and deionized water, take out the membrane and put it into the mixed solution to fully immerse and hydrate More than 24 hours.

[0026] 2) Make a 1:5 mixed solution of vinyltrichlorosilane and ethanol, put the fully hydrated Nafion117 membrane in step 1) into the organosilane solution for 10 minutes, take it out, wash with methanol to remove the residual silane solution on the membrane surface, Transfer the film to a vacuum drying oven at 80°C to complete the reaction and dry it for more than 24 hours and weigh it. The surface functional group is hydroxyl, and the inorganic composite is a nano-scale silicon oxide network structure. The amount of silicon oxide is 10.14%. composite film.

Embodiment 3

[0028] 1) Place 4cm×4cm Nafion-117 membrane in 5%H 2 o 2 , 1.0mol / l H 2 SO 4 1. Treat in deionized water at 80°C for 1h, dry in a vacuum oven at 80°C for 24h, weigh, make a 2:1 mixed solution of methanol and deionized water, take out the membrane and put it into the mixed solution to fully immerse and hydrate More than 24 hours.

[0029] 2) Make a 1:4 mixed solution of 3-mercaptopropyltrimethoxysilane and acetone, put the fully hydrated Nafon117 membrane in step 1) into the organosilane solution for 5 minutes, take it out, wash with methanol to remove the residue on the membrane surface Transfer the film to a vacuum drying oven at 80°C for complete reaction and weigh it after drying for more than 24 hours. The surface functional group is 3-mercaptopropyl, and the inorganic composite is a nano-scale silicon oxide network structure. The amount of silicon oxide was 3.6% of the composite film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com