Nanometre collagen oligopeptide and its producing method

A nano-glue and oligopeptide technology, which is applied in the field of nano-collagen oligopeptides and its preparation, can solve the problems of low skin permeability and no nutritional value of collagen oligopeptides, so as to improve immunity, improve bioavailability, The effect of enhancing collagen activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Example 1: After the fresh pigskin is depilated, it is scraped, washed, and crushed into small pieces, soaked in 10 times the volume of saturated lime water for 40 days, rinsed with water, washed until nearly neutral, and then washed with 10 times the volume 1M HCl, soaked for 48 hours, washed with water until the pH is equal to about 4, to obtain pretreated pigskin. Take 200g of pretreated pigskin, put it into the reaction bottle of the rotary evaporator, add 1800g of water, add 2g of pepsin and 2g of trypsin respectively, keep a vacuum of 1-10KPa, hydrolyze at a constant temperature of 50°C for 4 hours, and then add 2g of papain , adjusted the pH value to 5 with 0.1M NaOH, and hydrolyzed at 60°C for 3 hours under the same vacuum condition. Then add 2 grams of matrix metalloproteinase, continue to keep constant temperature at 60° C., and hydrolyze under the same vacuum condition for 3 hours. Heat to 100°C for 10 minutes, cool to 60°C, filter with absorbent cotton, and...

Embodiment 2

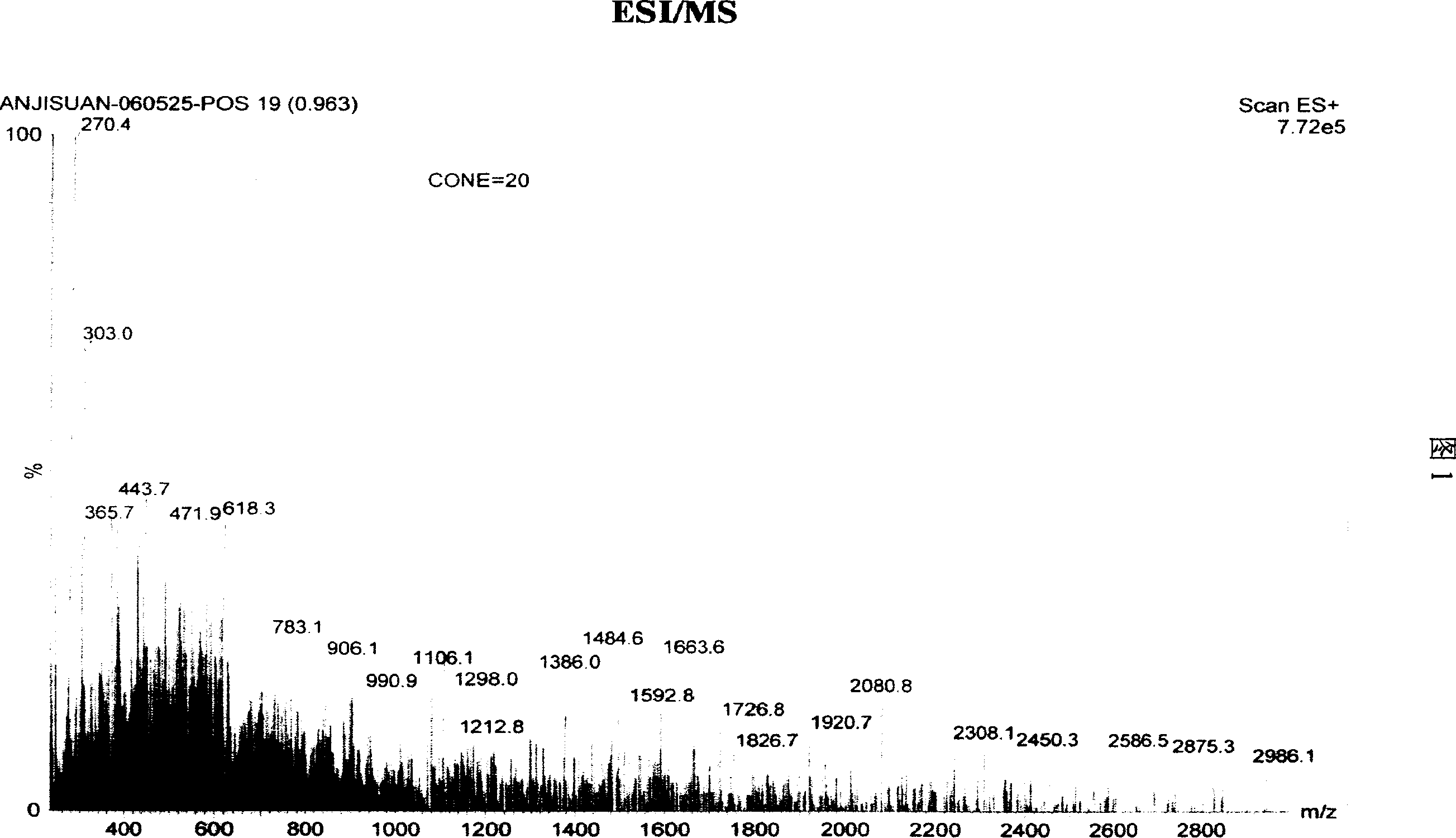

[0049] Fig. 1 is a schematic diagram of the molecular weight distribution of the nano-collagen oligopeptide detected by electrospray mass spectrometry (ESI / MS). The results of ESI / MS analysis show that 90% of the molecular weight of the product is distributed between 100 and 1000D, which is a combination of small molecules from dipeptide to heptapeptide. The product is a collagen oligopeptide, and its molecular size and length should be between a few nanometers and a dozen nanometers, which is a nanoscale molecule, so the hydrolyzed product is a nano-collagen oligopeptide. Example 2: After the fresh pigskin is depilated, it is scraped, washed, and crushed into small pieces, soaked in 10 times the volume of saturated lime water for 40 days, rinsed with water, washed until nearly neutral, and then washed with 10 times the volume 1M HCl, soaked for 48 hours, washed with water until the pH is equal to about 4, to obtain pretreated pigskin. Take 200g of pretreated pigskin, put it ...

Embodiment 3

[0051] Example 3: After the fresh pigskin is depilated, it is scraped off, washed, and crushed into small pieces, soaked in 10 times the volume of saturated lime water for 40 days, rinsed with water, washed until nearly neutral, and then washed with 10 times the volume 1M HCl, soaked for 48 hours, and the water sank to a pH equal to about 4 to obtain pretreated pigskin. Take 200g of pretreated pigskin, put it into the reaction bottle of the rotary evaporator, add 1800g of water, add 2g of pepsin and 2g of trypsin respectively, keep a vacuum of 10-30KPa, hydrolyze at a constant temperature of 40°C for 4 hours, then add 2g of papain , use 0.1M NaOH to wither the pH value to 5, and under the same vacuum condition, hydrolyze at a constant temperature of 70°C for 3 hours. Then add 2 grams of matrix metalloproteinase, continue to keep constant temperature at 60° C., and hydrolyze under the same vacuum condition for 3 hours. Heat to 100°C for 10 minutes, cool to 60°C, filter with ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com