Metal remover

A demetallization agent and a one-element technology, which is applied in the field of demetallization agents for removing metal impurities from hydrocarbon raw materials, can solve problems such as inability to completely remove iron elements in hydrocarbon raw materials, and achieve the effects of low cost, readily available raw materials and simple use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The preparation method of the demetallization agent includes uniformly mixing the above-mentioned organic phosphonic acid and organic carboxylic acid, and the mixing may or may not include uniformly mixing the solubilizer with the above-mentioned organic phosphonic acid and organic carboxylic acid. The way of mixing is well known to those skilled in the art, and will not be repeated here.

[0021] The demetallization agent provided by the invention can demetallize various hydrocarbon raw materials containing metal impurities. The hydrocarbon raw material can be mineral oil and various fractions thereof, such as one of crude oil, atmospheric residue, vacuum residue, deasphalted oil, shale oil, lubricating oil, diesel oil, gasoline, and coal liquefied oil. species or several. The total content of metal impurities in the hydrocarbon feedstock is preferably 1-300 μg / g. The metal impurities may be one or more of iron, calcium, magnesium, zinc and sodium.

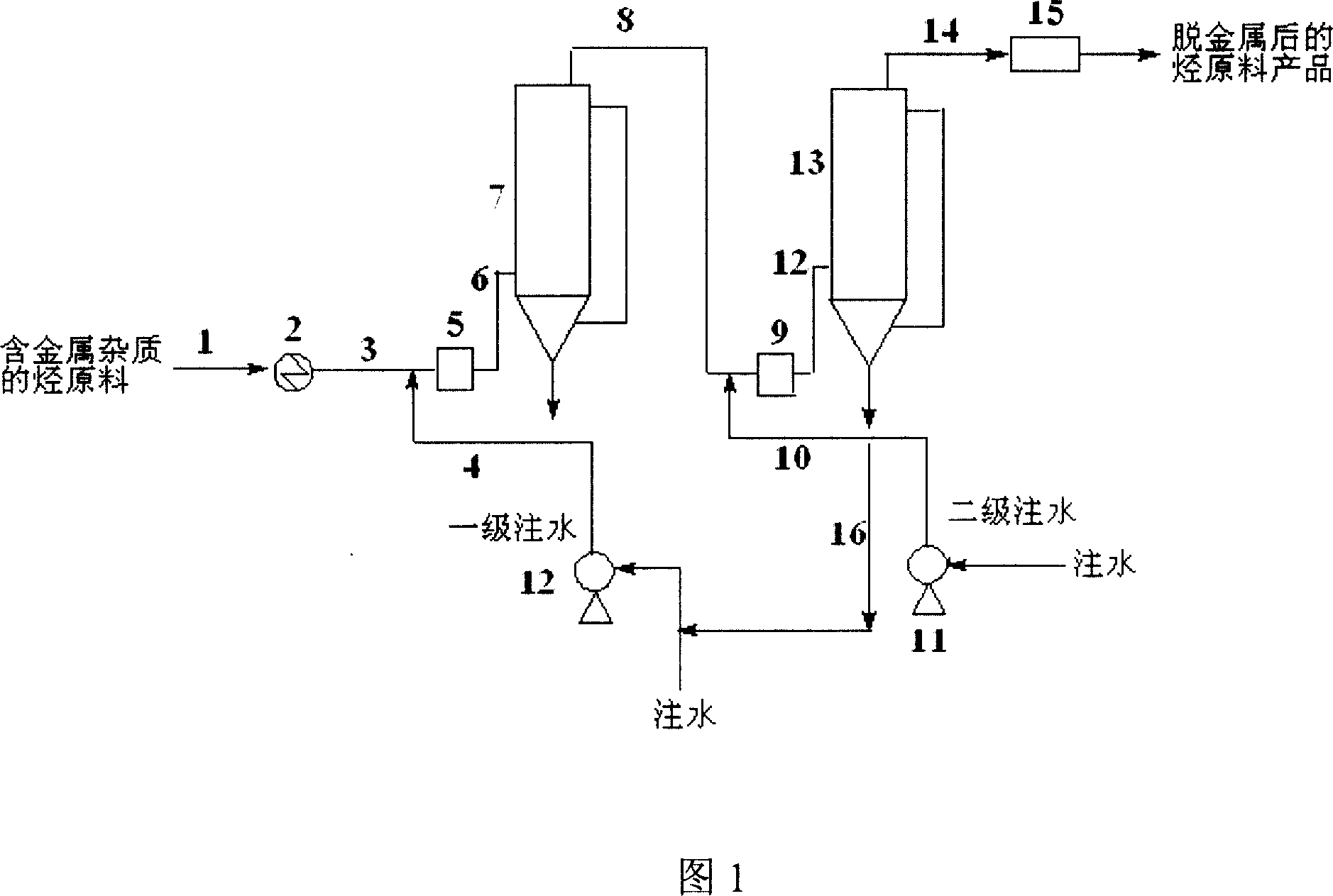

[0022] The deme...

Embodiment 1

[0029] This example is used to illustrate the preparation of the demetallization agent provided by the present invention.

[0030] Mix 35 parts by weight of citric acid, 10 parts by weight of oxalic acid, 10 parts by weight of formic acid, 15 parts by weight of maleic acid, and 30 parts by weight of hydroxyethylidene diphosphonic acid to obtain a metal removal agent containing organic carboxylic acid and organic phosphonic acid.

Embodiment 2

[0032] This example is used to illustrate the preparation of the demetallization agent provided by the present invention.

[0033] 20 parts by weight of citric acid, 10 parts by weight of oxalic acid, 10 parts by weight of acetic acid, 20 parts by weight of ethanol, 30 parts by weight of hydroxyethylidene diphosphonic acid, and 10 parts by weight of 2-hydroxyphosphinoacetic acid are mixed uniformly to obtain organic carboxylic acid, Demetallizer for organic phosphonic acids and solubilizers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com