Quartz base bismuth gallium erbium aluminium codoped optical fiber and its production method

A production method, quartz technology, applied in the direction of manufacturing tools, glass manufacturing equipment, etc., to achieve the effect of shortening length, improving cleanliness and maintaining gain efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A barrier layer is first deposited in the ultrapure quartz tube by using a modified chemical vapor deposition method (MCVD), and the refractive index of the barrier layer is consistent with the refractive index of the quartz tube. Then deposit the innermost layer, that is, the core layer. The temperature of the deposited core layer is relatively low, between 1200°C and 1300°C. The deposited core layer is a loose (foamy) white opaque layer. The raw material for depositing the loose layer is Silicon tetrachloride (SiCl 4 ) and oxygen (O 2 ), the obtained loose layer composition is only silicon dioxide (SiO 2 ). Then use the online doping method to soak the loose layer in the pre-prepared mixed solution of bismuth, gallium, erbium and aluminum, and continue soaking for about one hour after the opaque loose layer becomes transparent.

[0027] Before soaking, the key is to prepare a high-purity mixed salt solution, and the doping composition of the salt solution is also t...

Embodiment 2

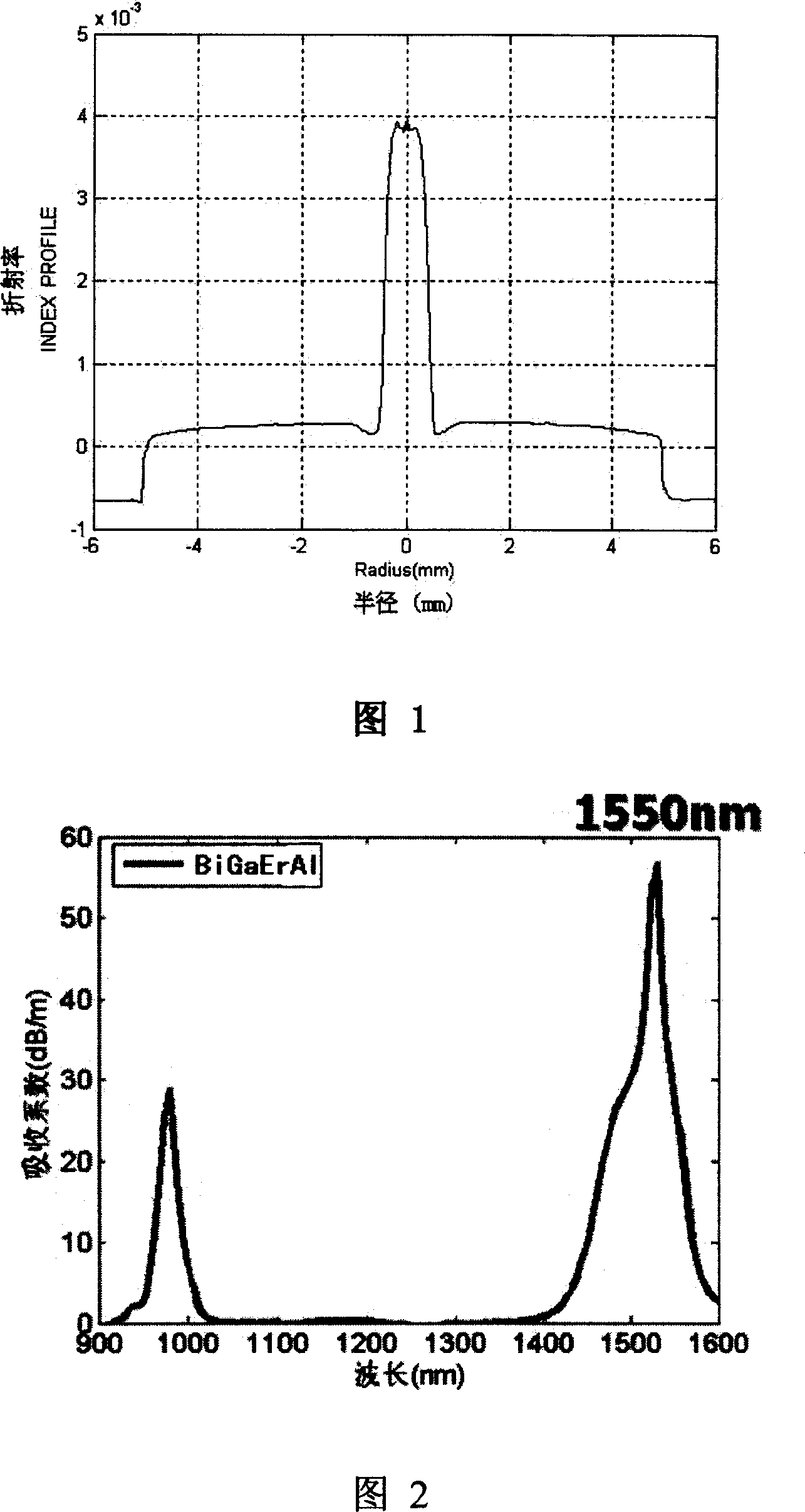

[0032] The MCVD method is used to deposit the barrier layer in the pure quartz tube, and then start to deposit the loose layer. When depositing the fiber core loose layer, the raw material gas is composed of silicon tetrachloride (SiCl 4 ), germanium tetrachloride (GeCl 4 ) and oxygen (O 2 ), a mixture of silicon dioxide and germanium dioxide is formed by high-temperature reaction, wherein germanium dioxide is mainly used to increase the refractive index of the core area, and at the same time reduce the temperature when depositing the loose layer, and appropriately change the quartz network structure. When the loose layer in the core area is made of a mixture of silicon dioxide and germanium dioxide, the concentration of bismuth, gallium, erbium, and aluminum prepared in the solution doping process should be appropriately lowered because the doping of germanium increases the refractive index of the fiber core. .

[0033] Following the same steps as in Example 1: solution pre...

Embodiment 3

[0035] The MCVD method is used to deposit the barrier layer in the pure quartz tube, and then start to deposit the loose layer. When depositing the fiber core loose layer, the raw material gas is composed of silicon tetrachloride (SiCl 4 ), sulfur hexafluoride (SF 6 ) and oxygen (O 2 ), a mixture of silicon dioxide and silicon oxyfluoride is formed by high temperature reaction. Since doping with fluorine reduces the refractive index of the fiber core, the concentration of bismuth, gallium, erbium, and aluminum can be appropriately increased during the doping process to make the fiber core have a suitable refractive index. When the concentrations of bismuth, gallium, erbium, and aluminum solutions are not increased, this fluorine-doped silica-based fiber core has a lower refractive index than pure silica-based fiber cores, and is more suitable for making optical fibers with large effective core areas. In cladding-pumped high-power fiber lasers and amplifiers.

[0036] Simila...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com