Semiconductor device and method of manufacturing the same

a semiconductor and semiconductor technology, applied in the field of semiconductor devices, can solve the problems of increasing the cost of production, increasing the cost of a product, and high unit cost of the semiconductor substrate, and achieve the effect of excellent conformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

[0194] In this embodiment, manufacturing steps of a semiconductor device having the structure of the present invention will be described with reference to FIGS. 4A to 4D. Specifically, there is shown an example in which a driving circuit constituted by CMOS circuits in which an NTFT (N-channel TFT) and a PTFT (P-channel TFT) using a polysilicon film are complementarily combined, and a pixel matrix circuit constituted by NTFTs are integrally formed on the same substrate.

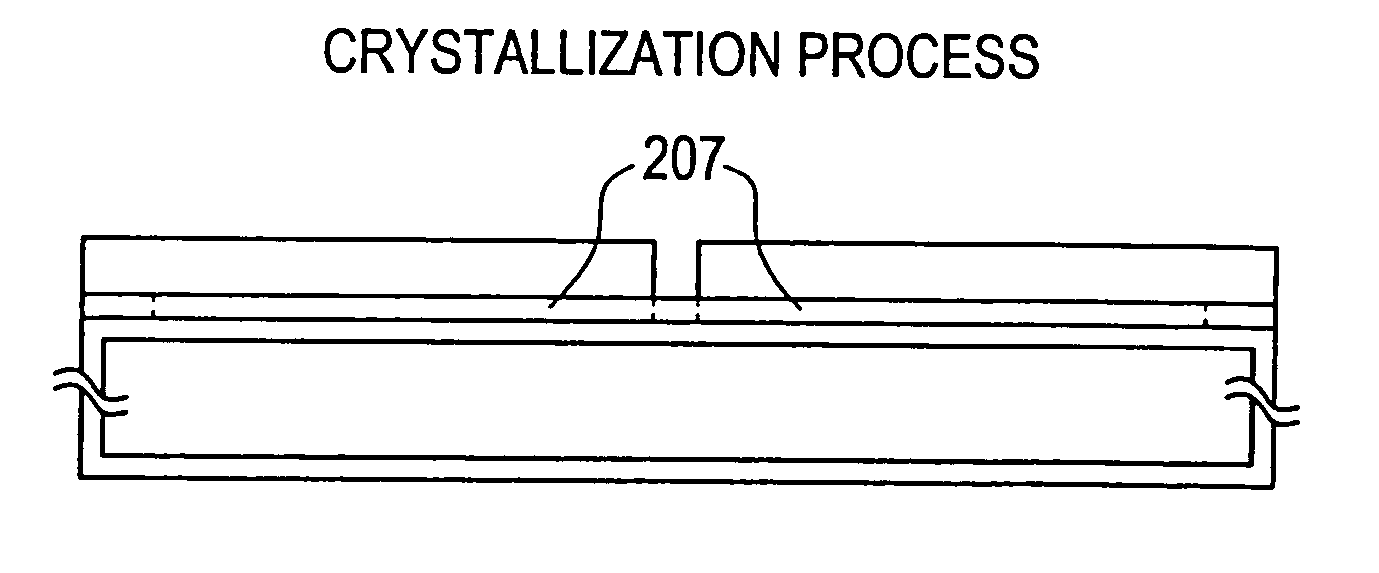

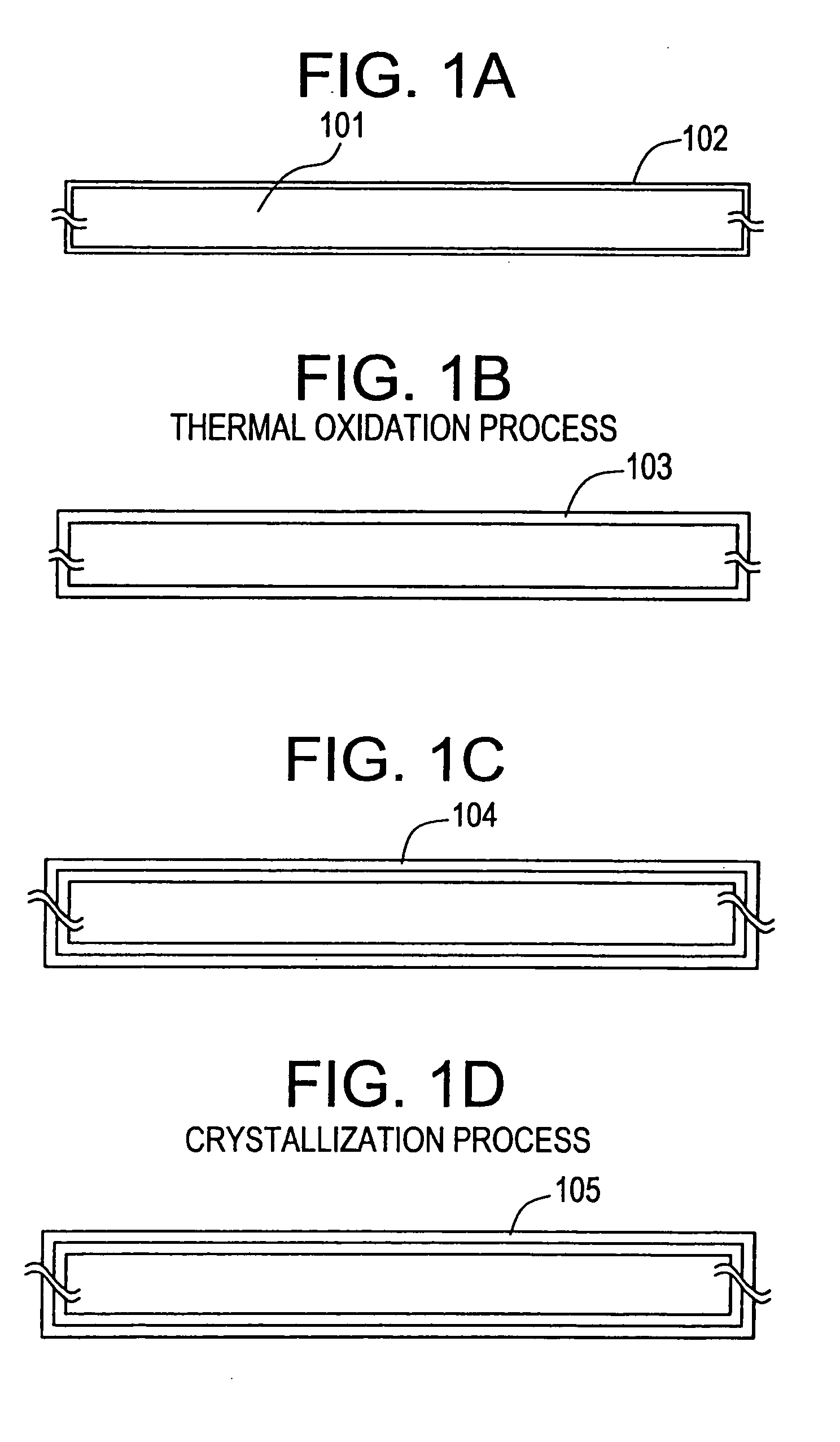

[0195] First, in accordance with the manufacturing steps explained by using FIGS. 1A to 1D, a crystalline silicon film (typically, polycrystal silicon film) 105 is formed. Then the polycrystal silicon film 105 is patterned to form active layers 403 to 405. At this time, although the polycrystal silicon film formed on the side surface of a crystallized glass 401 is removed, the polycrystal silicon film on the back surface remains as it is.

[0196] Reference numeral 403 denotes the active layer of the PTFT of the CMOS c...

embodiment 2

[0220] In this embodiment, manufacturing steps of a semiconductor device having the structure of the present invention will be described with reference to FIGS. 6A to 6D. Specifically, there is shown an example in which a driving circuit and a logic circuit constituted by CMOS circuits in which an NTFT (N-channel TFT) and a PTFT (P-channel TFT) using CGS are complementarily combined, and a pixel matrix circuit constituted by NTFTs are integrally formed on the same substrate.

[0221] The logic circuit is a signal processing circuit having functions different from those of a driving circuit typified by a shift register or the like, and is a general term of a circuit for performing such signal processing as is conventionally carried out by an external IC, such as a D / A converter circuit, a memory circuit, a γ correction circuit, a calculation processing circuit, and the like.

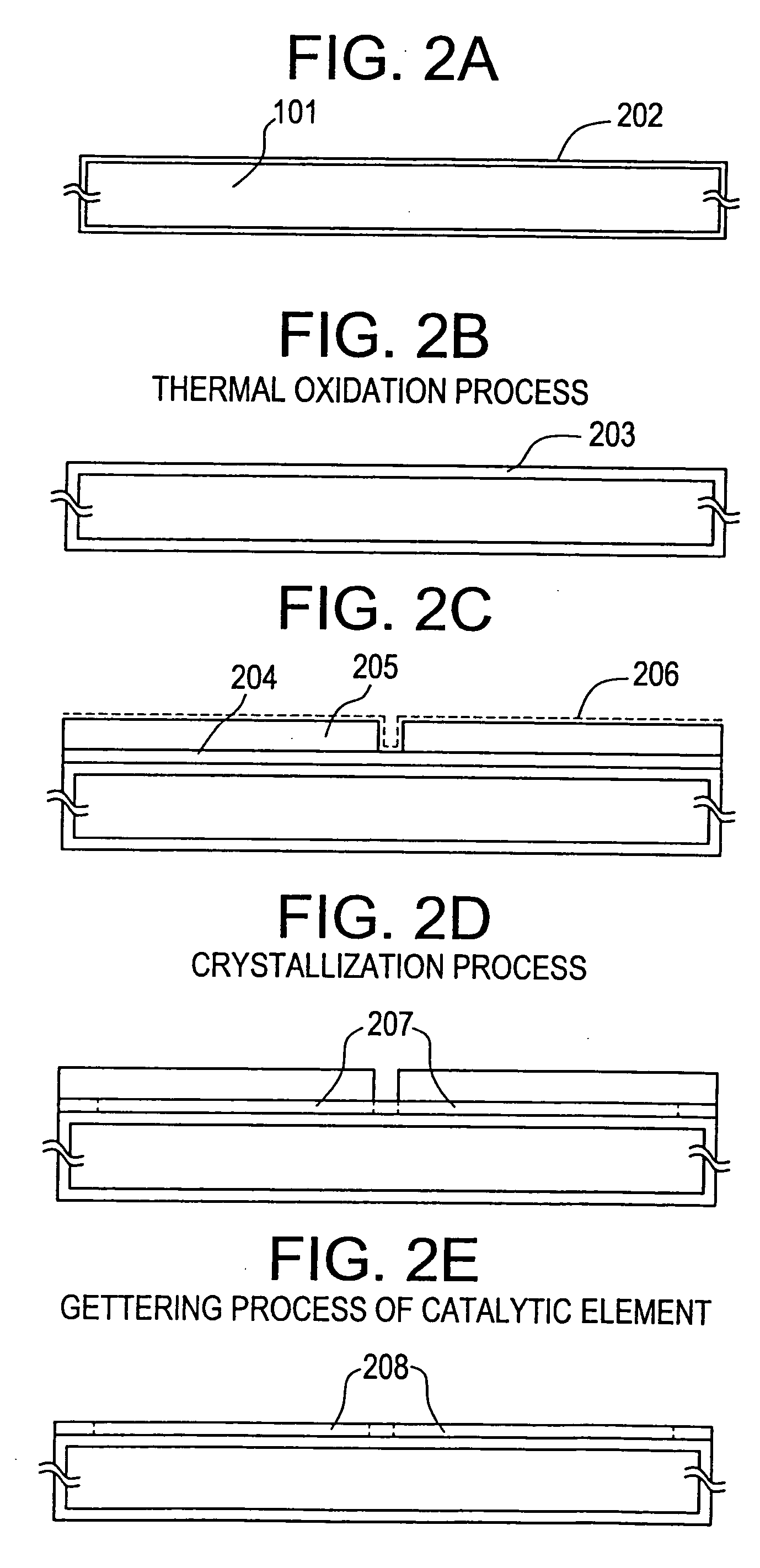

[0222] First, in accordance with the manufacturing steps explained by using FIGS. 2A to 2E, steps up to the gett...

embodiment 3

[0249] In this embodiment, an example in which an insulating silicon film for protecting crystallized glass in the structure of Embodiment 1 is formed by a low pressure CVD method, will be described.

[0250] First, as a substrate, crystallized glass having the composition of SiO2: 52.5, Al2O3: 26.5, MgO: 11.9, TiO2: 11.4 is prepared. This is non-alkaline cordierite-based crystallized glass using TiO2 as a nucleus forming agent.

[0251] Next, a silicon nitride oxide film is formed on the front surface, the back surface, and the side surface of the crystallized glass. In this embodiment, the silicon nitride oxide film is formed by a low pressure CVD method using silane (SiH4) and nitrous oxide (N2O) as a film forming gas.

[0252] In this case, a film forming temperature is 800 to 850° C. (in this embodiment, 850° C.), and the flow rates of the respective film forming gases are made SiH4: 10 to 30 sccm and N2O: 300 to 900 sccm. It is appropriate that the reaction pressure is made 0.5 to 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat resistance | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com