Ultrafine metal oxide particle dispersion liquid and ultrafine metal oxide particle thin film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

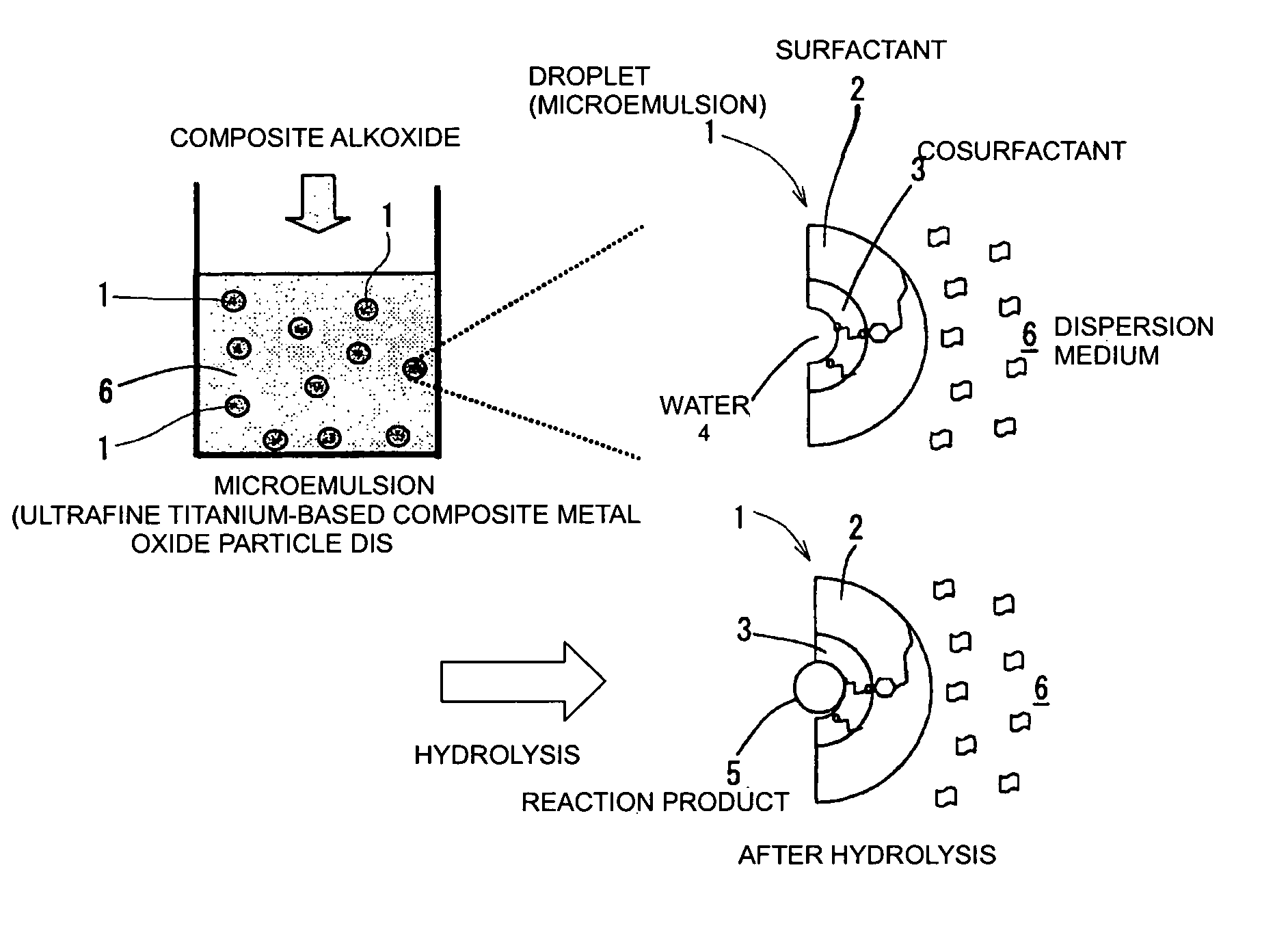

[0084] First, 4 g of barium isopropoxide was mixed into 160 ml of isopropyl alcohol in a glove box containing an argon atmosphere to prepare a barium alkoxide solution. An equimolar amount of titanium isopropoxide solution was added dropwise into the barium alkoxide solution, which was mixed overnight to obtain a light yellow, transparent barium-titanium composite alkoxide stock solution.

[0085] A W / O microemulsion was prepared by mixing water, cyclohexane, as a dispersion medium, NP-10 ((p—C9H19)—C6H4—O—(CH2CH2O)10CH2CH2OH), as a surfactant, and 1-octanol, as a cosurfactant, at a ratio of 0.2:150:7.5:9, respectively, while bubbling the mixture with an argon gas. The barium-titanium composite alkoxide stock solution was then added to the microemulsion with a micropipette so that the content of water in the microemulsion was 1.2 times the amount of water required for the hydrolysis of the barium-titanium composite alkoxide. This mixture was stirred in a glove box containing an argon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Dissociation constant | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com