Solar cell and method of fabricating the same

a technology of solar cells and insulating films, applied in the field of solar cells, can solve the problems of poor passivation effect, small reflection loss, low conversion efficiency , etc., and achieve the effect of reducing the substrate temperature and improving the passivation characteristic of the insulating film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

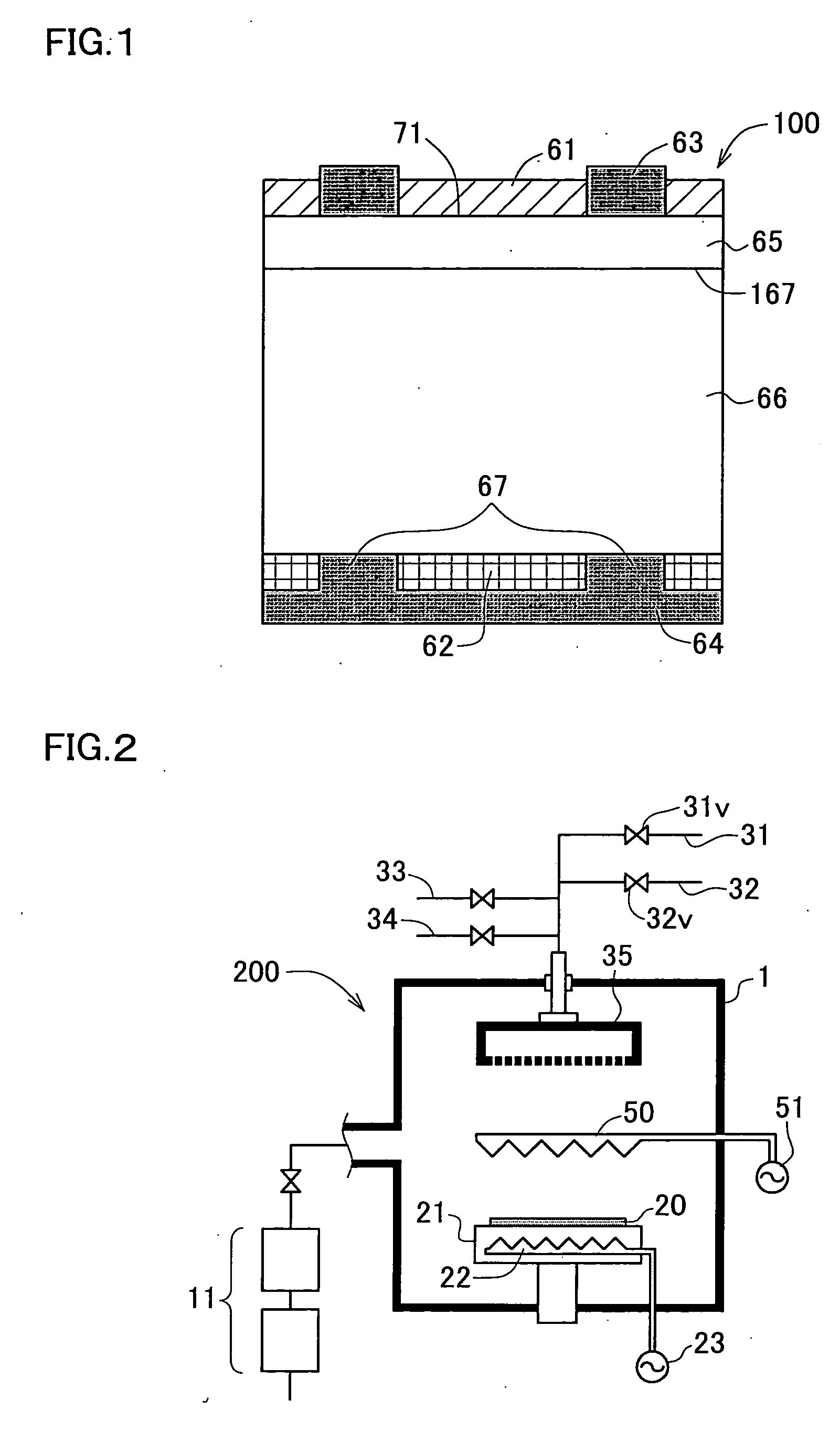

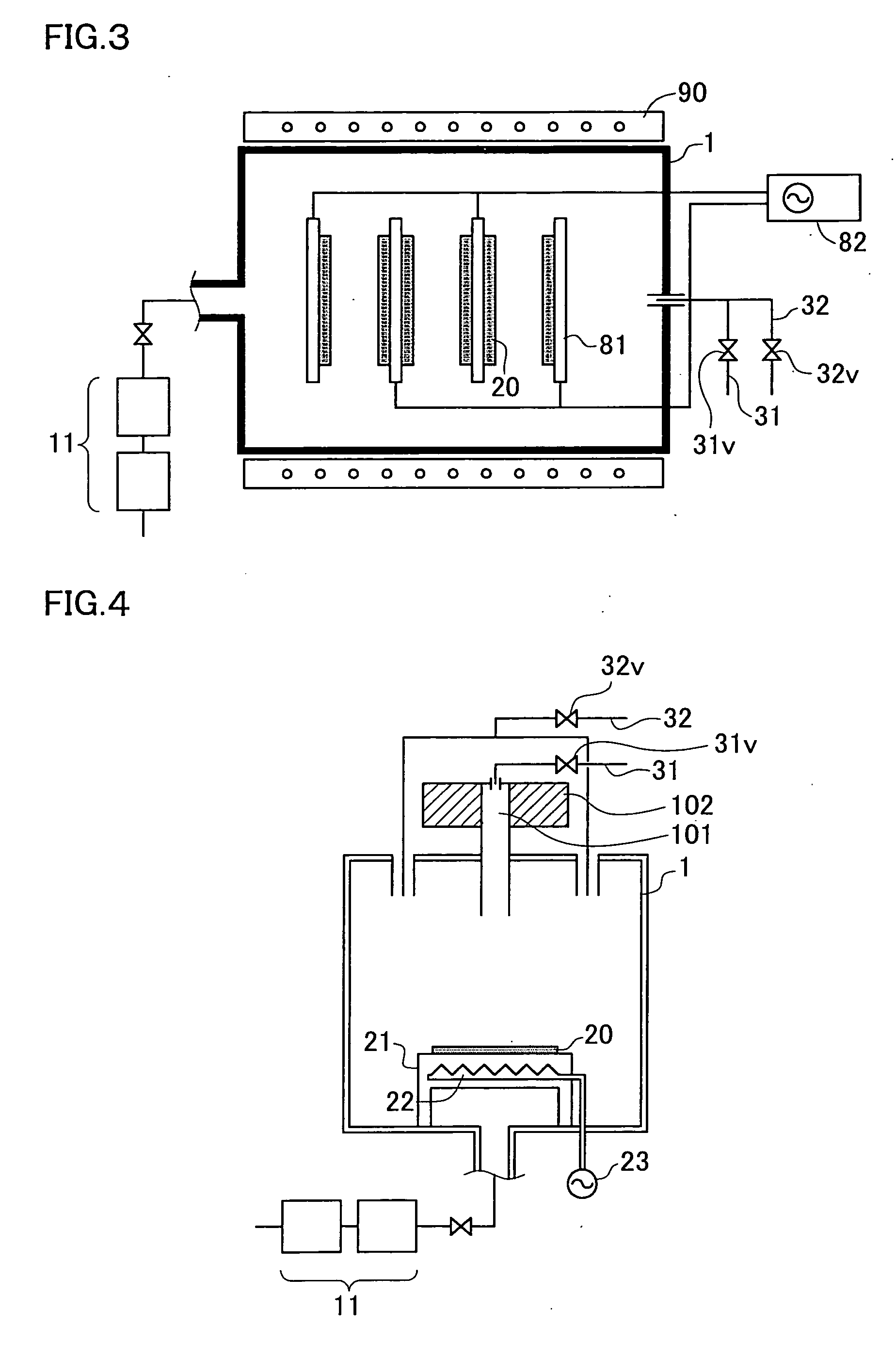

Method used

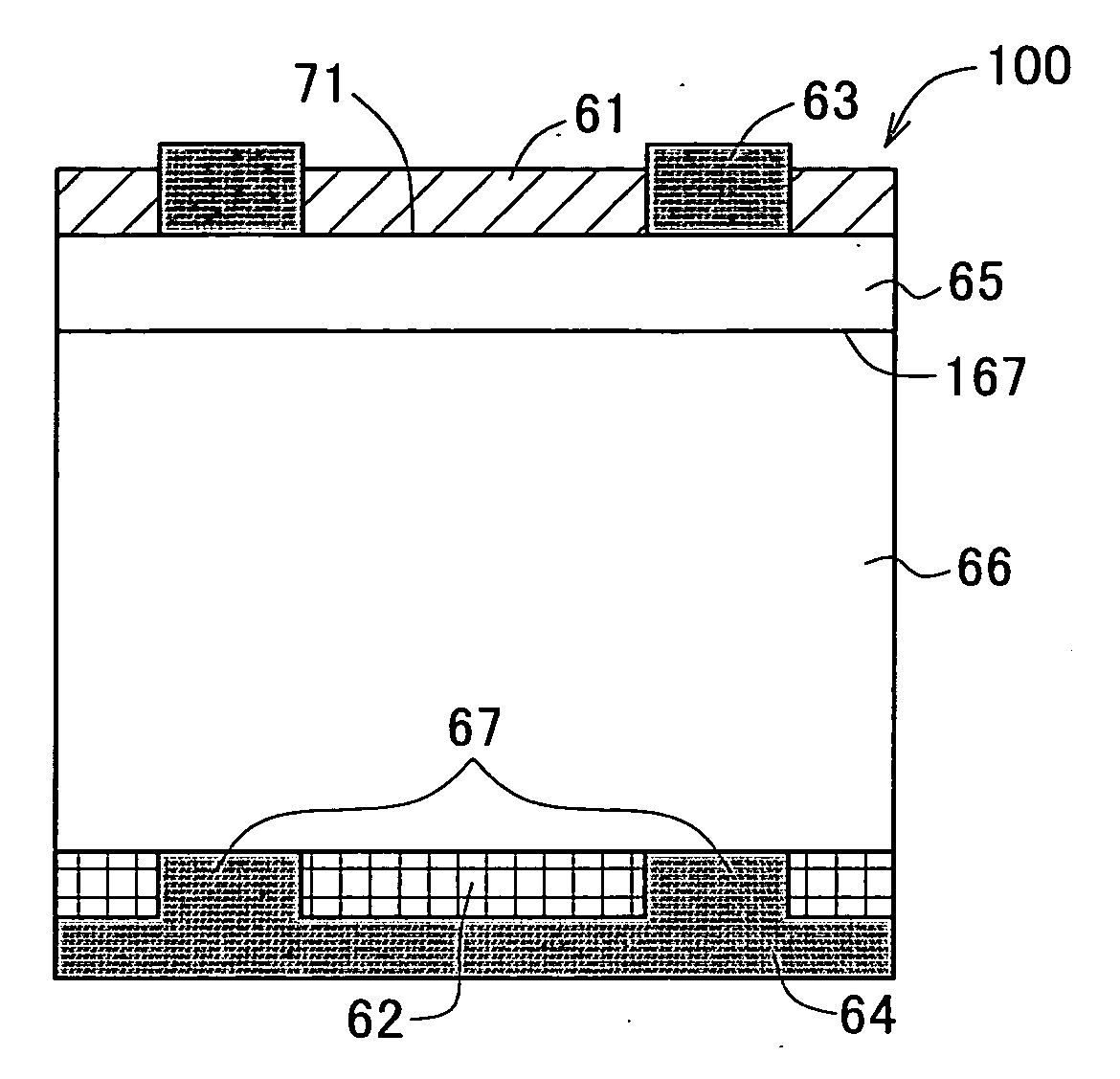

Image

Examples

experiment 1

[0070] A 3-inch circular (100) single crystal silicon substrate (FZ method, B doped) having a resistivity of 1.5 Ωcm was cleaned with 2% hydrofluoric acid for 1 minute, rinsed with ultra-pure water for 5 minutes, and dried by blowing a dry nitrogen. Thereafter a silicon nitride film of 80 nm thick, having a refractive index of 2.4 (Si / N atomic ratio=1.48: without hydrogen dilution), was formed on both surfaces thereof by the catalytic CVD process. Next, an effective lifetime was measured using a lifetime scanner while irradiating a white bias light of 0.5 sun, and the surface recombination velocity was calculated on the basis of a result of lifetime measurement of the same substrate but subjected to chemical passivation (iodine / ethanol treatment). On the other hand, using a 400-W metal halogen lamp as a light source, one surface of the sample was exposed to ultraviolet radiation, from which wavelength component of 320 nm or shorter is cut by a filter, for 32 hours and 128 hours, and...

experiment 2

[0071] The silicon substrate was cleaned and dried according to the procedures similar to as described in Experiment 1, and by the catalytic CVD process, the substrate was surface-treated using ammonia gas, on both surfaces of which the silicon nitride film having a refractive index of 2.4 was deposited, and then a similar measurement was carried out.

experiment 3

[0072] The silicon substrate was cleaned and dried according to the procedures similar to as described in Experiment 1, and by the catalytic CVD process, the substrate was surface-treated using ammonia gas, on both surfaces of which the silicon nitride film having a refractive index of 2.4 was deposited, post-treated using hydrogen gas, and then a similar measurement was carried out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com