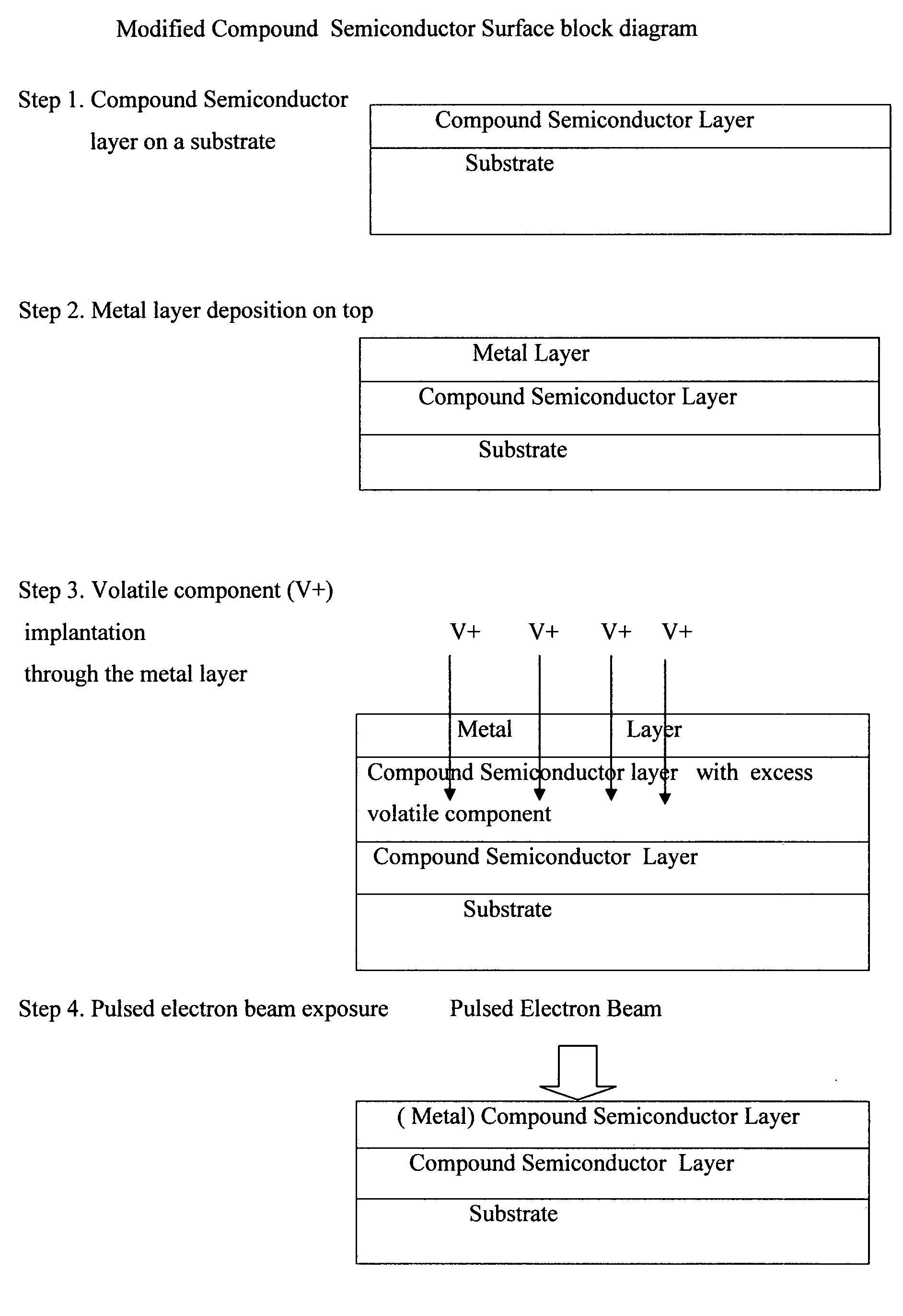

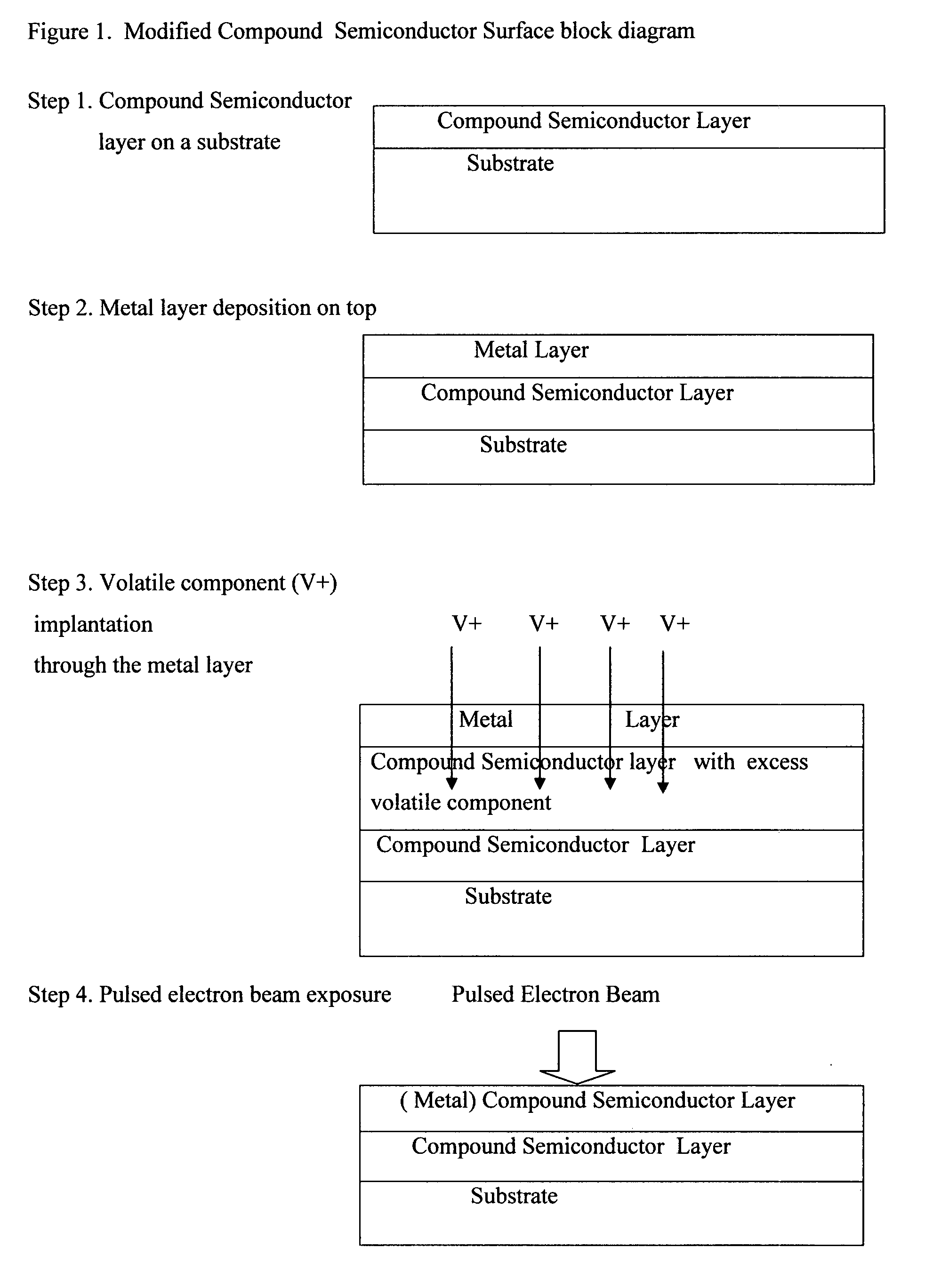

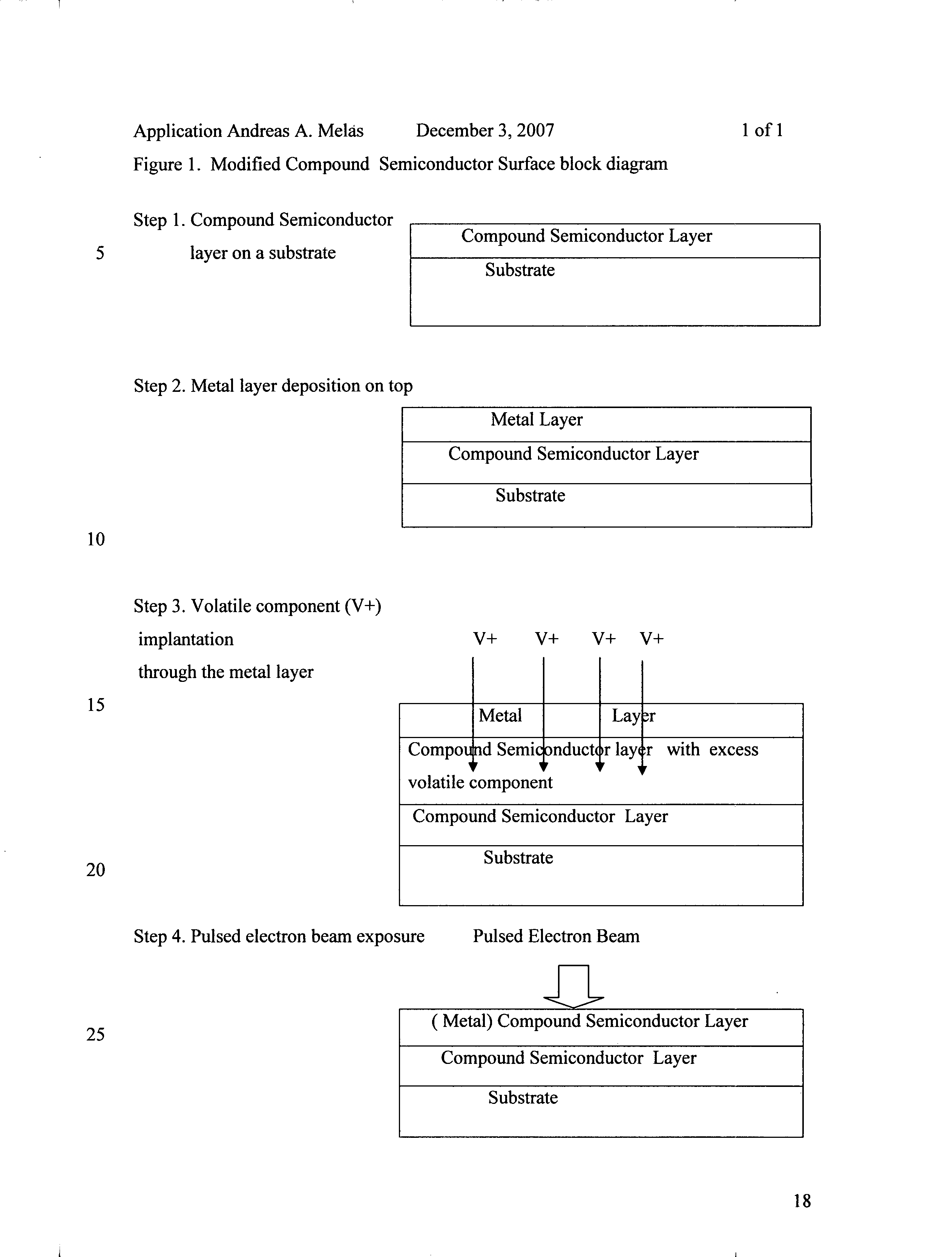

Compound semiconductor modified surface by use of pulsed electron beam and ion implantation through a deposited metal layer

a technology of deposited metal layer and modified surface, which is applied in the direction of polycrystalline material growth, crystal growth process, chemistry apparatus and processes, etc., can solve the problems of overly difficult conditions to achieve on a practical scale, slow light energy transfer techniques such as flash lamps, and undesirable temperature rise in the entire substra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Pulsed Electron Beam Through Deposited Aluminum Layer

[0026] A. Deposit a high purity layer of Aluminum metal in the range of 0.01 to several micrometers thick. This can be by ebeam evaporation or by a Chemical Vapor Deposition or other technique, as long as high purity is achieved. The use of Aluminum is significant not only because it is a Group III metal and highly conductive but also because AlxGa1-xN layer alloy can be produced. At concentrations below about 1 atomic percent, the Aluminum will not alter significantly the material properties of GaN.

[0027] B. Use a pulsed electron beam as wide as 100 mmOD, generated by capacitor discharge. Typically, an electric field of approximately 10 to 100 KiloVolt is used, a total of 1-50 Kilo Amperes, with a pulse width under a microsecond, typically of 80 to 500 nanoseconds, resulting in an energy fluence from 0.1 to 10 Joules per cm2. The electron beam pulse may be repeated as necessary to optimize the results.

[0028] C. The result of t...

example 2

Pulsed Electron Beam Through Deposited Indium Layer

[0031] A variation of Example 1 is where Indium metal is used instead of Aluminum. This is particularly important since in this case, the resulting InxGa1-xN layer, which has a larger crystal lattice further improves the GaN crystal structure by expansion.

example 3

Pulsed Electron Beam Through Deposited Boron Layer on Group III-Nitride

[0032] Another variation of Example 1 is to use Boron which has the advantage to produce a better metal contact due to the higher energy bandgap than Gallium Nitride itself.

PUM

| Property | Measurement | Unit |

|---|---|---|

| partial pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| Outside Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com