Directed evolution of cyp52a12 gene and its use in dicarboxylic acid production

a technology of cyp52a12 and dicarboxylic acid, which is applied in the field of preparing a long-chain dicarboxylic acid producing strain, can solve the problems of huge obstacles to serious affecting the development of long-chain dicarboxylic acid in the industry, and many challenges in chemical synthesis. achieve the effect of significantly shortening the fermentation cycl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

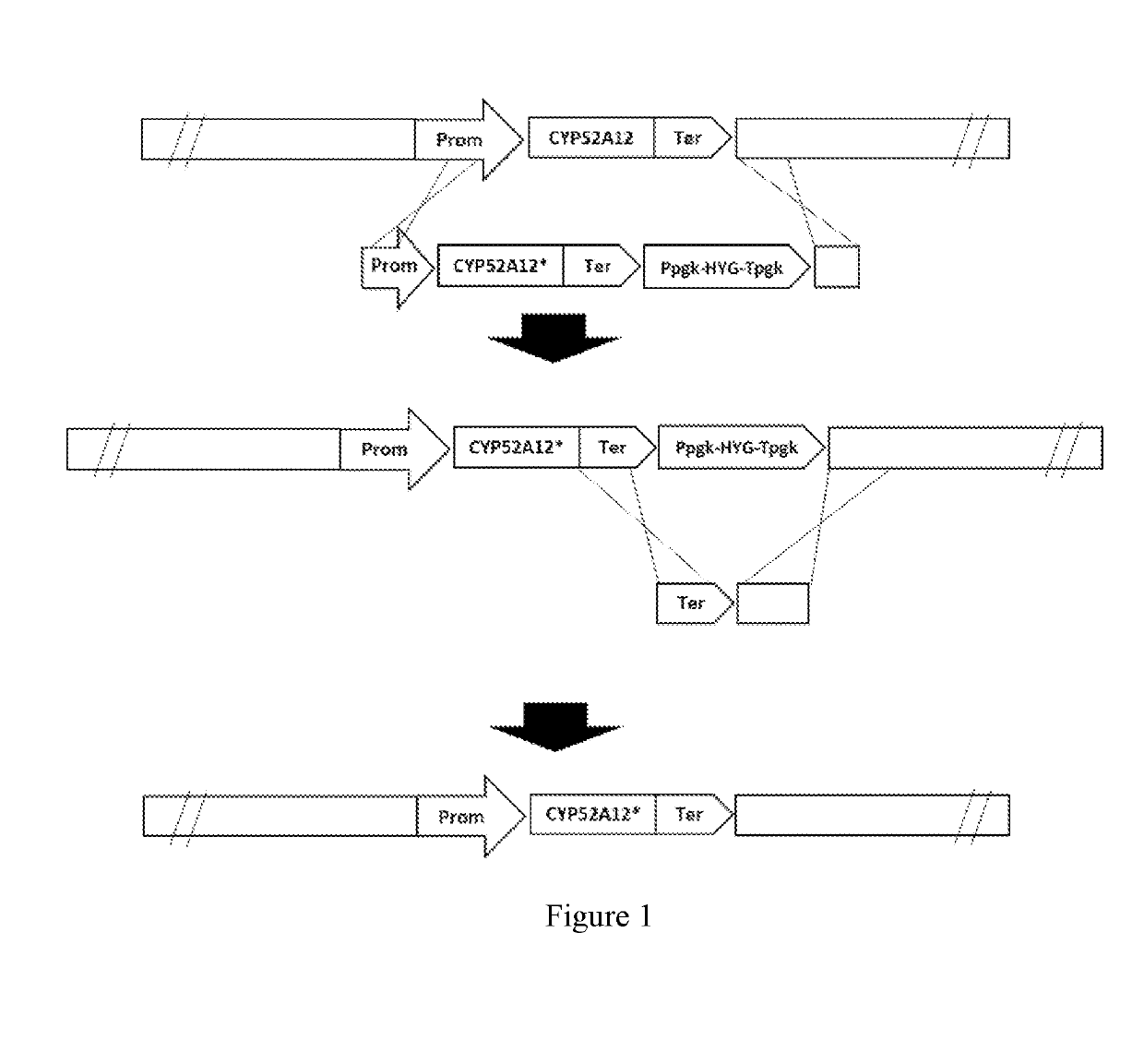

Method used

Image

Examples

example 1

edia and Methods for Culture and Fermentation as Well as for Detecting a Dicarboxylic Acid

[0086]1. YPD medium formula (w / v) was: 2% peptone, 2% glucose and 1% yeast extract (OXOID, LP0021). 1.5-2% agar powder was added to form a solid media.

[0087]During culturing, a single colony was picked in a 2 ml centrifuge tube containing 1 ml YPD liquid medium, incubated at 30° C. in a 250 RPM shaker for 1 day.

[0088]2. Seed medium formula (w / v): sucrose 10 to 20 g / L, yeast extract 3 to 8 g / L, industrial fermentation corn syrup (for short, corn syrup, with total nitrogen content 2.5 wt %) 2 to 4 g / L, KH2PO4 4 to 12 g / L, urea 0.5 to 4 g / L (separately sterilized at 115° C. for 20 min), and the substrate for fermentation was n-dodecane 20 mL / L.

[0089]During culturing, the inoculum obtained in step 1 was inoculated into a 500 mL shake flask containing 30 mL seed medium, wherein the amount of inoculum was 3-5%, and incubated at 30° C. in a 250 RPM shaker until OD620 reached 0.8 (after 30-fold dilutio...

example 2

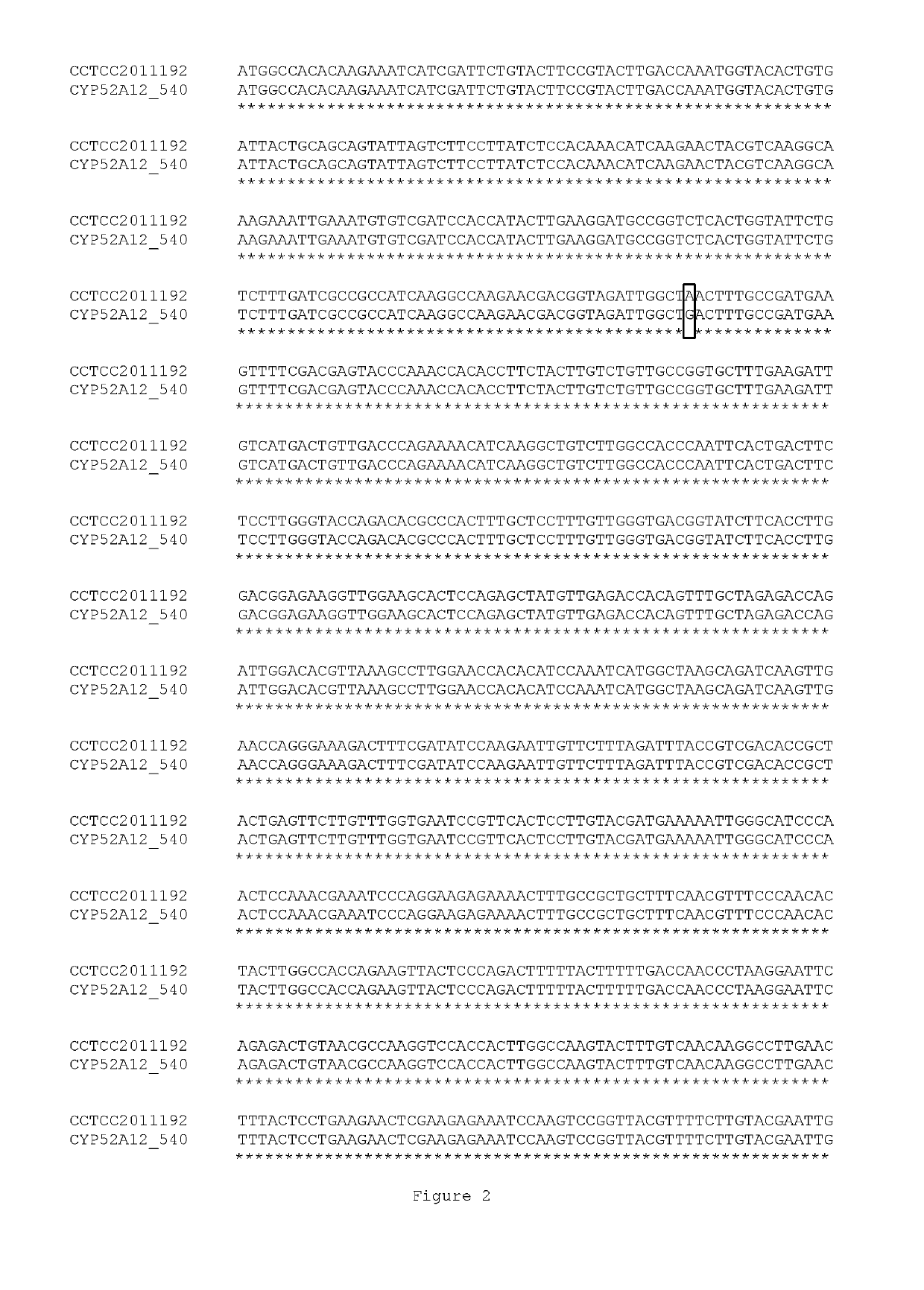

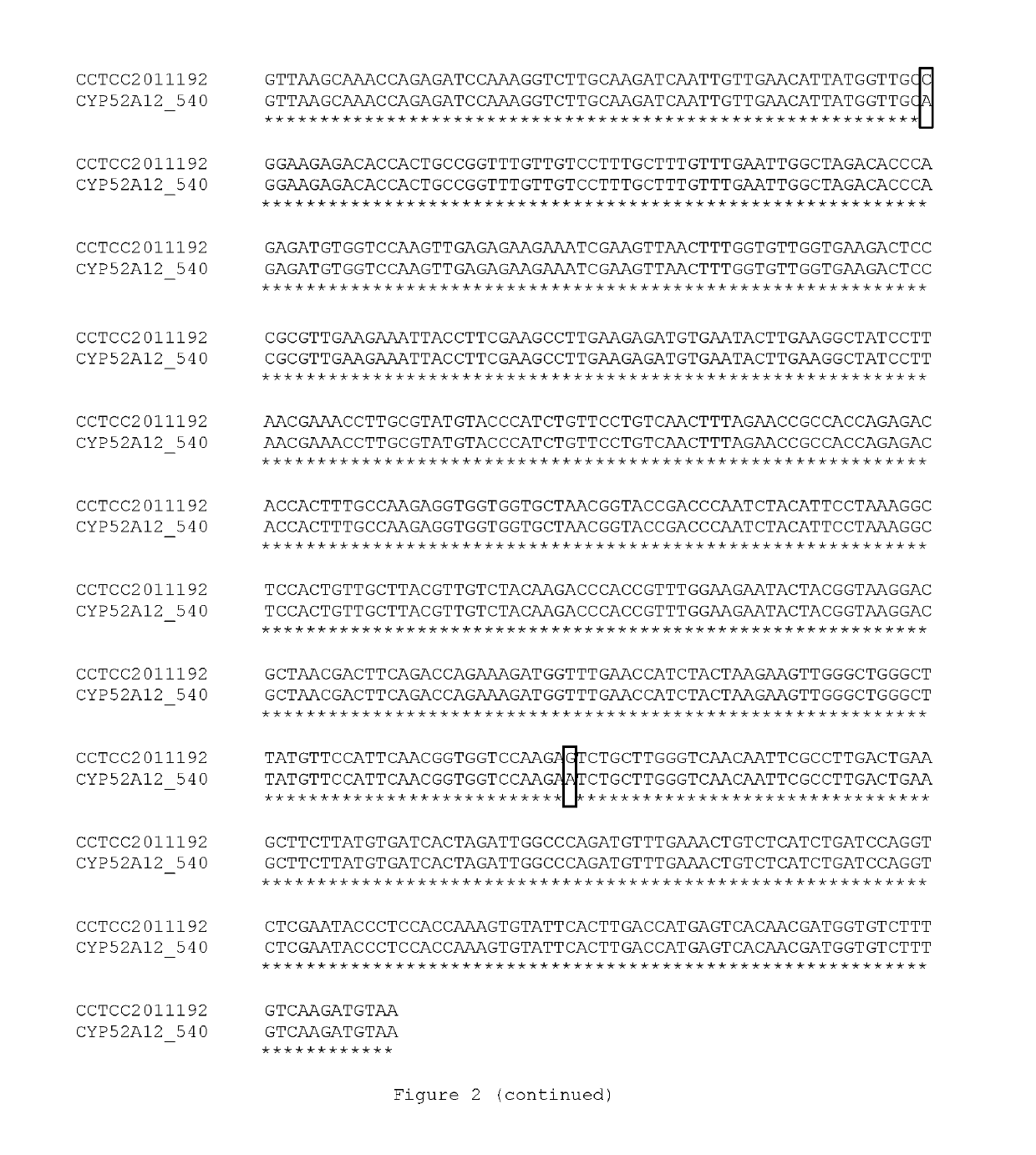

on of CYP52A12 Mutation Template

[0094]1. Preparation of the CYP52A12 mutation template.

[0095]The genomic DNA of Candida CCTCC M 2011192 was extracted by using Ezup Yeast Genomic DNA Extraction Kit (Sangon, Cat No. 518257). A method with liquid nitrogen grinding was used in favor of increasing the cell wall disruption efficiency. Genomic DNA obtained by this method was used as template for error-prone PCR.

[0096]2. Error-prone PCR

[0097]The concentration of Mg2+ was adjusted (2-8 mM) and the CYP52A12 gene was amplified by error-prone PCR using Taq DNA Polymerase (Takara, Cat No. R00113).

[0098](PCR condition was: Step 1: 98° C. for 30 s, step 2: 98° C. for 10 s, 55° C. for 30 s, 72° C. for 2 m 20 s, 35 cycles in total, Step 3: 72° C. for 5 m).

[0099]The primers were as follows:

CYP52A12-F:(SEQ ID NO: 1)5′-CAAAACAGCACTCCGCTTGT-3′,CYP52A12-R:(SEQ ID NO: 2)5′-GGATGACGTGTGTGGCTTGA-3′,

[0100]The PCR product was subjected to electrophoresis on a 1% agarose gel and recovered and purified by using...

example 3

on of Homologous Recombination Template

[0101]All DNA fragments in this example were obtained by amplification using PrimeSTAR® HS High Fidelity DNA polymerase (Takara, R040A). The DNA fragments were subjected to electrophoresis on a 1% agarose gel, followed by recovery and purification by using the Axygen Gel Recovery Kit.

[0102](1) Amplification of the resistance selection marker (HYG, the hygromycin resistance gene). The amplification template was the vector pCIB2 (SEQ ID NO: 3) owned by our company. The primer sequences were as follows:

CYP52A12_HYG-F:(SEQ ID NO: 4)5′-TCAAGCCACACACGTCATCCGCATGCGAACCCGAAAATGG-3′,CYP52A12_HYG-R:(SEQ ID NO: 5)5′-GATGTGGTGATGGGTGGGCTGCTAGCAGCTGGATTTCACT-3′.

[0103]The PCR reaction condition was as follows:

[0104]Step 1: 98° C. for 30 s,

[0105]Step 2: 98° C. for 10 s, 55° C. for 30 s, 72° C. for 1 m 50 s, 5 cycles,

[0106]Step 3: 98° C. for 10 s, 72° C. for 2 m, 25 cycles,

[0107]Step 4: 72° C. for 5 m.

[0108]The resulting product, named HYG, was verified by seq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| pH | aaaaa | aaaaa |

| pH | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com