Method for preparing multi-element metal oxide containing nickel-cobalt and method for carrying out surface coating decoration

A multi-metal and oxide technology, applied in nickel compounds, cobalt compounds, chemical instruments and methods, etc., can solve the problems of poor surface coating and modification, complex ion exchange method steps, poor processing behavior of pole pieces, etc. Improved surface structure and particle distribution, improved charge-discharge specific capacity and cycle performance, and improved pole piece processing behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

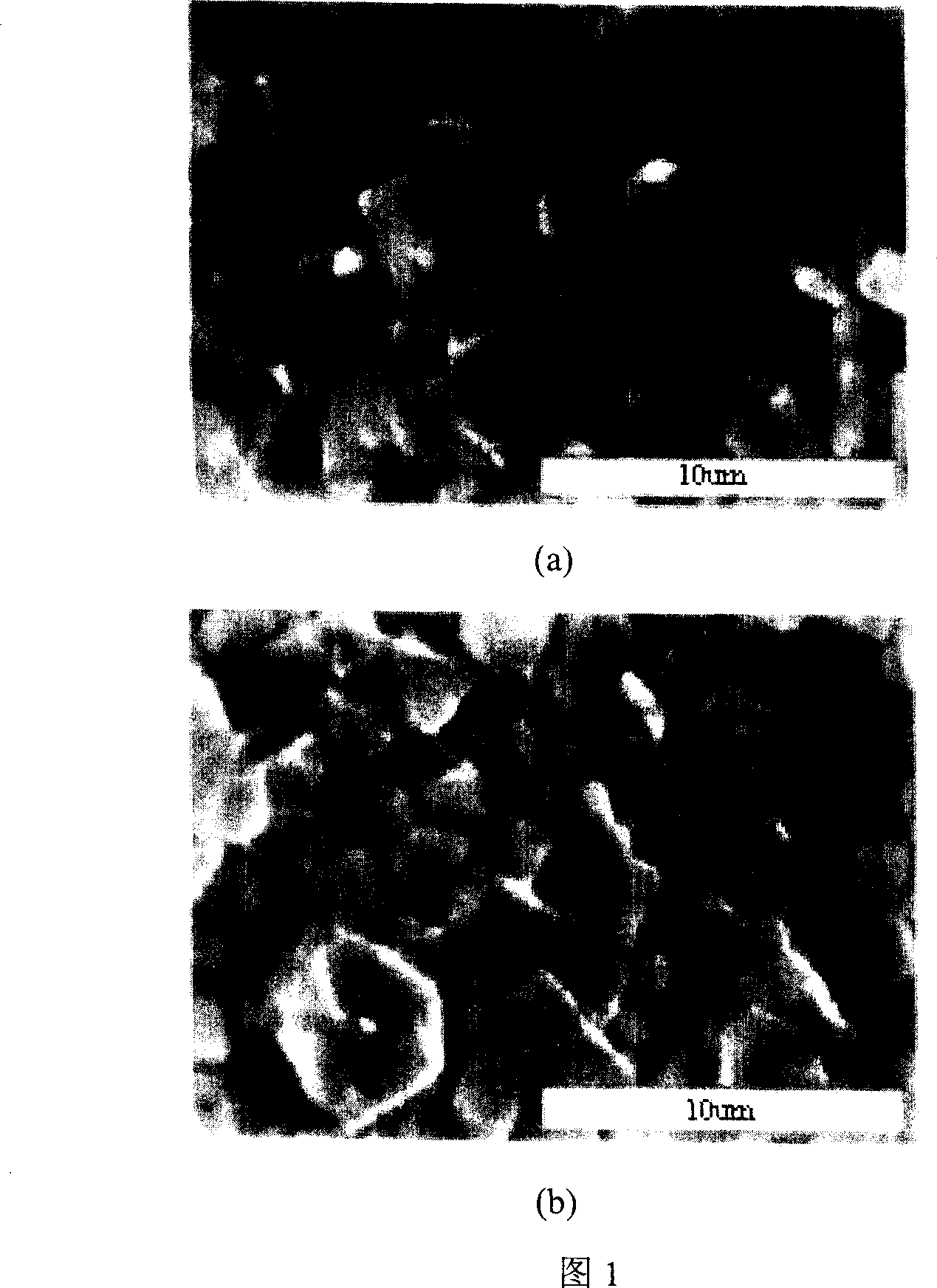

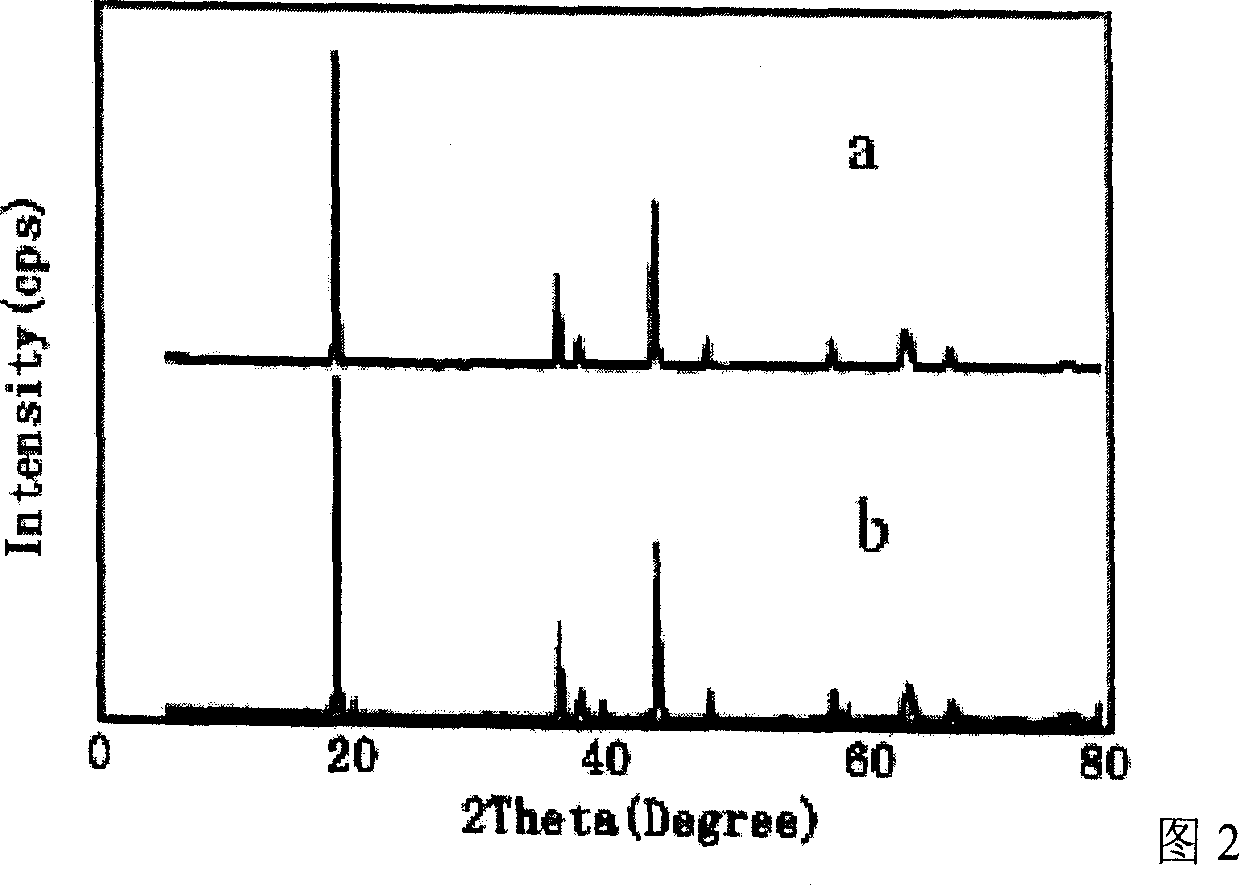

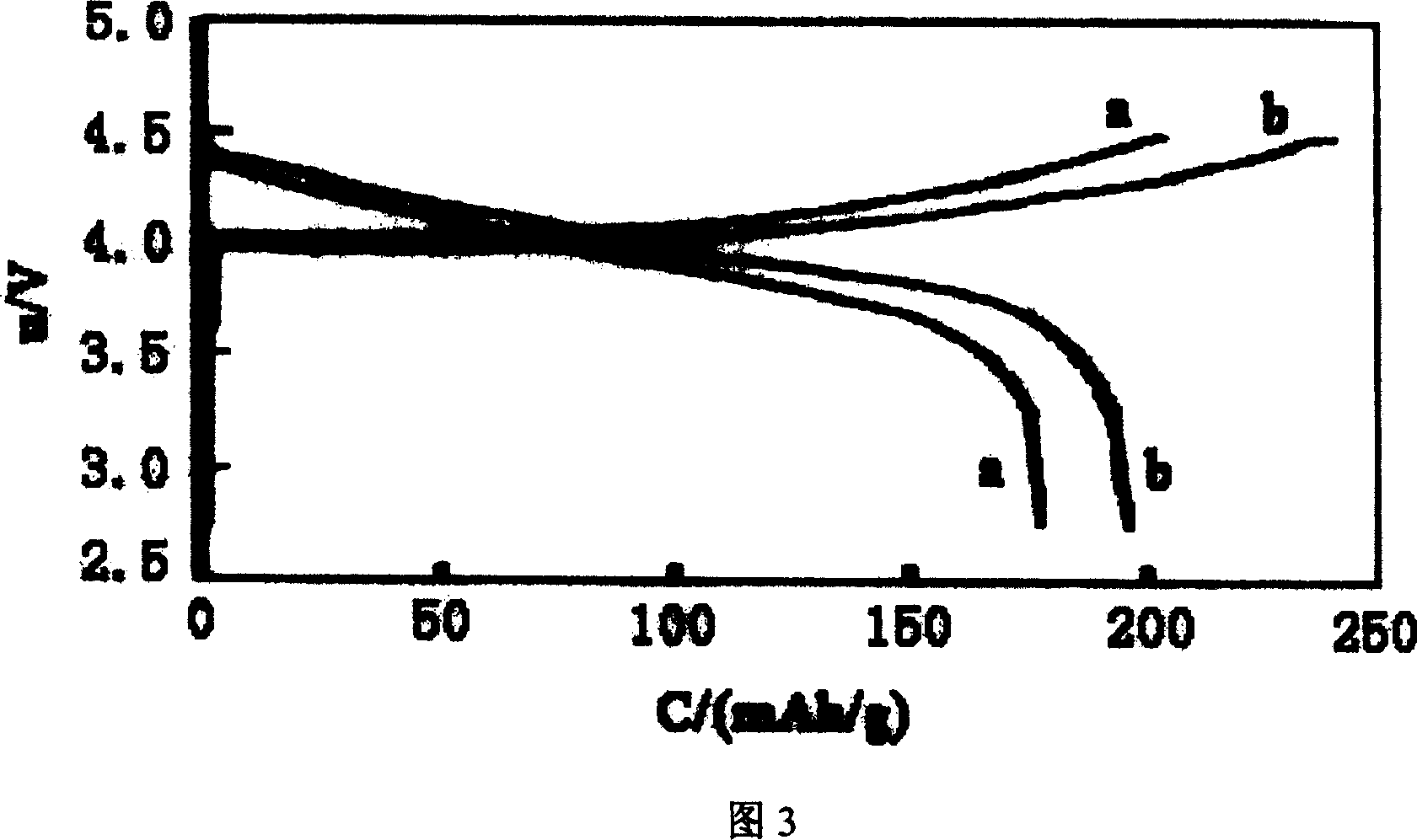

[0047] Take nickel (Ni), cobalt (Co), and manganese (Mn) sulfates at a molar ratio of 1:1:1 and mix them to prepare 1 L of an aqueous solution with a total metal content of 1 mole. Under nitrogen atmosphere and constant stirring, Slowly drop it into 1L, 2.2M NaOH aqueous solution at 50°C. After 8 hours, the Ni-Co-Mn composite hydroxide was separated, washed several times with distilled water, and then dried in vacuum at 100°C for 10 hours, and its water content was accurately measured. After one part and lithium hydroxide monohydrate (LiOH·H 2 O) Mixed grinding at a molar ratio of 1:1.06, then placed in an intelligent control muffle furnace, under dry air, the temperature was raised to 300°C at 2°C / min and kept at a constant temperature for 6 hours for the first heat treatment, and then heated at 2°C / min to raise the temperature to 750°C and keep the temperature for 16 hours for sintering, then naturally cool the product to room temperature, grind and sieve to obtain the posi...

Embodiment 2

[0052]Mix nickel (Ni) and cobalt (Co) nitrates at a molar ratio of 8:2 to prepare 1L of an aqueous solution with a total metal content of 2 moles, and slowly drop it into 1L under an argon atmosphere and constant stirring. In 4.4M 50°C KOH aqueous solution, the Ni-Co composite hydroxide was separated after 9 hours, washed several times with distilled water and then dried in vacuum at 120°C for 8 hours, and mixed with lithium hydroxide monohydrate (LiOH·H 2 O) After mixing and grinding at a molar ratio of 1:1.05, place it in an intelligent control muffle furnace. Under dry air, heat up to 320°C at 5°C / min and keep the temperature for 5 hours for the first heat treatment, and then heat at 5°C / min The temperature was raised to 750°C and kept at a constant temperature for 18 hours for sintering, and then the product was naturally cooled to room temperature, ground and sieved to obtain the positive electrode active material LiNi 0.8 co 0.2 o 2 , and then carry out surface coating...

Embodiment 3

[0057] Take nickel (Ni), cobalt (Co), and iron (Fe) sulfates in a molar ratio of 5:3:2 and mix them to prepare 1L of an aqueous solution with a total metal content of 0.9 moles. Under nitrogen atmosphere and constant stirring, Slowly drop it into 1L, 2.2M NaOH aqueous solution at 40°C. After 10 hours, the Ni-Co-Fe composite hydroxide was separated, washed several times with distilled water, dried in vacuum at 120°C for 10 hours, and mixed with hydrogen monohydrate Lithium oxide (LiOH·H 2 O) After mixing and grinding at a molar ratio of 1:1.04, place it in an intelligently controlled muffle furnace. In dry air, heat up to 360°C at 5°C / min and keep the temperature for 7 hours for the first heat treatment, and then heat at 5°C / min. The temperature was raised to 750°C and kept at a constant temperature for 20 hours for sintering, then the product was naturally cooled to room temperature, ground and sieved to obtain the positive electrode active material LiNi 0.5 co 0.3 Fe 0.2 o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com