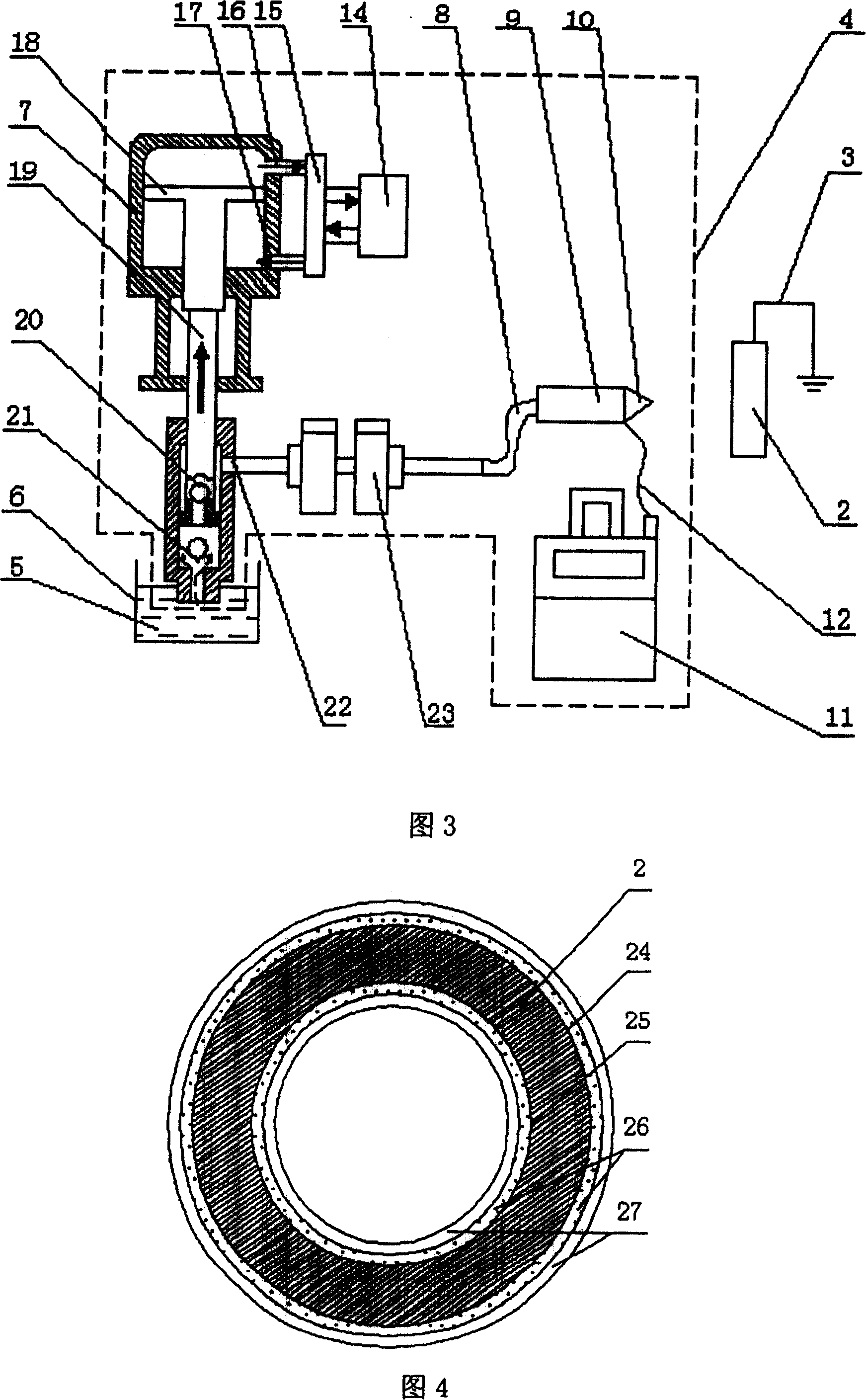

Medicinal coating production for vascular stand and electrostatic spraying apparatus

A vascular stent and drug coating technology, applied in the field of medical devices, can solve the problems of loss of paint, low paint atomization rate, difficult gas pressure control, etc., and achieve the effects of improved utilization, uniform coating, and increased rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In order to meet the clinical needs of XX Hospital, and to prepare small-sized drug-coated vascular stents, the technical solution of the present invention is adopted, and the preparation steps are as follows: the first step is to place the vascular stents in acetone, ethanol and distilled water for ultrasonic vibration cleaning for 15 minutes , dried in a vacuum oven at 80°C for 20 minutes; the second step is to prepare the coating, the ratio of the drug to the polymer carrier is 1:1 (mass ratio), and the concentration of the polymer carrier in its solvent is 1%, wherein the drug Be paclitaxel, polymer carrier be poly(lactide-glycolide) and solvent be chloroform; The preparation of the 3rd step drug coating, high pressure pump pressure is 0.4MPa, the voltage of electrostatic generator is 1kv, nozzle and The distance between the stents is 1cm. After the coating is atomized, the charged droplets are deposited on the surface of the stent under the joint action of high-volt...

Embodiment 2

[0040] The drug-eluting vascular stents prepared in Dalian ×× Hospital for animal experiments are as follows: the first step is to select 32 316L stainless steel balloon-expandable vascular stents (3.0×20cm), and place the vascular stents in acetone , ethanol and distilled water for 20 minutes, and dried in a vacuum oven at 70°C for 25 minutes; the second step is to prepare the coating, the ratio of drug to polymer carrier is 1:10 (mass ratio), and the polymer carrier is in the The concentration in the solvent is 5%, wherein the drug is rapamycin, the polymer carrier is poly(lactide-glycolide) and the solvent is tetrahydrofuran; the preparation of the third step drug coating is divided into 32 vascular stents Two batches, one batch of 16, the distance between each vascular stent in each batch is 2cm, the pressure of the high-pressure pump is 1MPa, the voltage of the electrostatic generator is 25kv, the distance between the nozzle and the stent is 10cm, after the paint is atomiz...

Embodiment 3

[0042] For the treatment of peripheral vascular lesions, a NiTi shape memory alloy self-expanding vascular stent was selected, and a total of 10 preparation steps were as follows: the first step was to place the NiTi shape memory alloy self-expanding vascular stent in acetone, ethanol and distilled water for ultrasonic vibration cleaning for 20 minutes. , dry in a vacuum oven at 60°C for 30 minutes; the second step is to prepare the coating, the ratio of the drug to the polymer carrier is 1:100 (mass ratio), and the concentration of the polymer carrier in its solvent is 15%, wherein the drug It is rapamycin, the polymer carrier is polylactide and the solvent is methylene chloride; the preparation of the third step drug coating, 10 vascular stents are connected in series with a distance of 5cm, the pressure of the high-pressure pump is 7MPa, and the voltage of the electrostatic generator It is 60kv, and the distance between the nozzle and the bracket is 20cm. After the paint is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com