Preparation method of highly magnesium-doped strontium plumbum titanate high dielectric adjustable film material

A technology for strontium lead titanate and thin film materials, which is applied in the field of preparation of strontium lead titanate high dielectric tunable thin film materials, can solve the problems of inability to form crystalline content, reduce the crystalline phase content of thin films, high PST thin films, etc. Good market prospect, improved dielectric constant, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

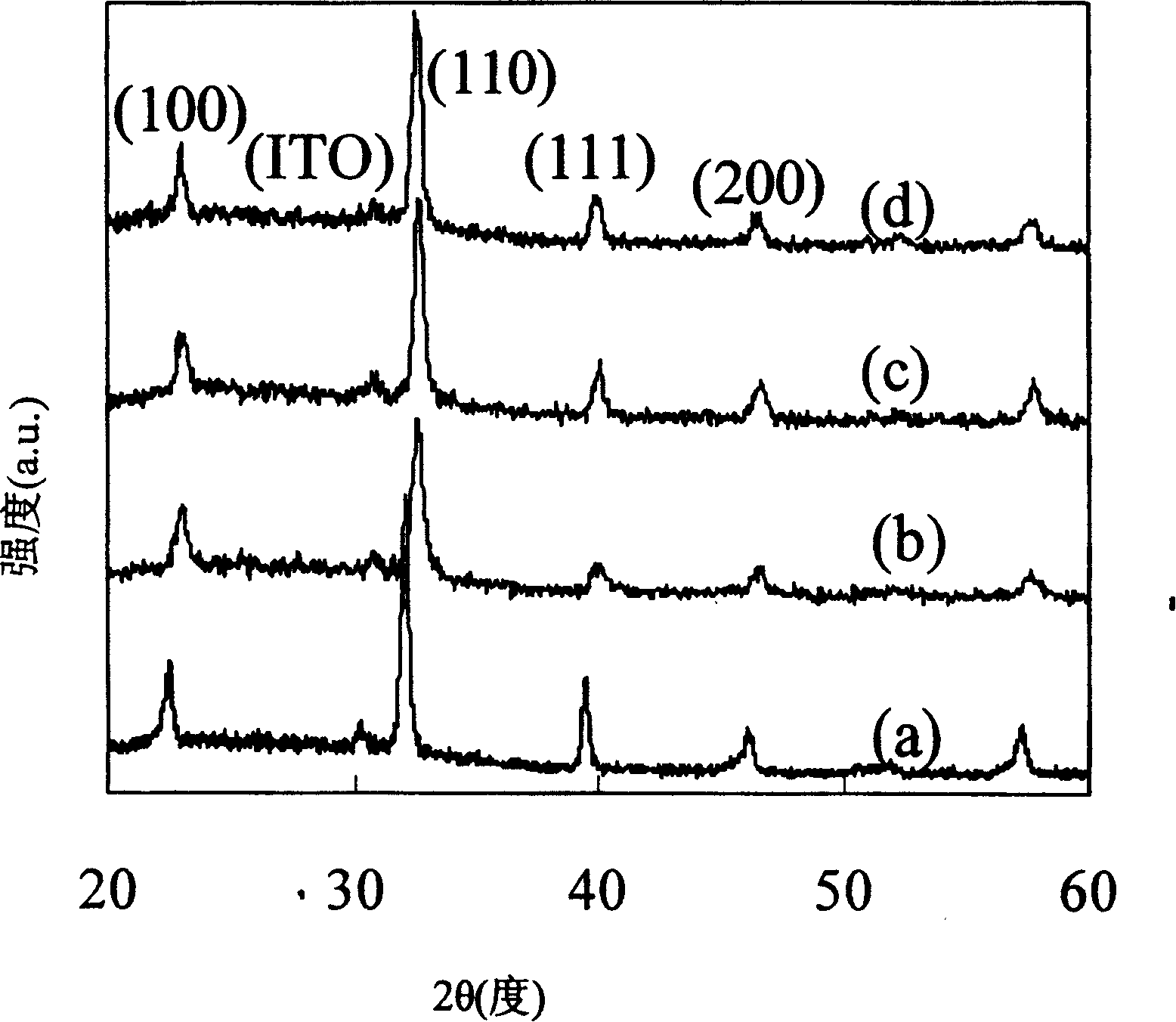

[0024] Lead acetate and strontium carbonate were dissolved in acetic acid by adding a small amount of deionized water, and the reaction was heated to obtain a colorless transparent solution; butyl titanate was dissolved in ethylene glycol methyl ether, and stirred until uniformly mixed. Mix the two solutions to obtain a Pb-Sr-Ti precursor sol, in which the concentrations of Pb, Sr, and Ti are: Pb: 0.22mol / L, Sr: 0.12mol / L, Ti: 0.35mol / L L. Immerse the glass substrate in the prepared sol system at a constant speed (4cm / min), place it for 10 seconds to make the glass substrate in a stable state, and then lift it at the same speed (4cm / min) until all the glass pieces are lifted out of the liquid surface, Then dry naturally in the air. Then put it into a high-temperature furnace, perform a rapid heat treatment at a temperature of 560° C. for 5 minutes, and after cooling, repeat the above operations to prepare a multilayer film. The prepared multilayer film was heat-treated at 59...

Embodiment 2

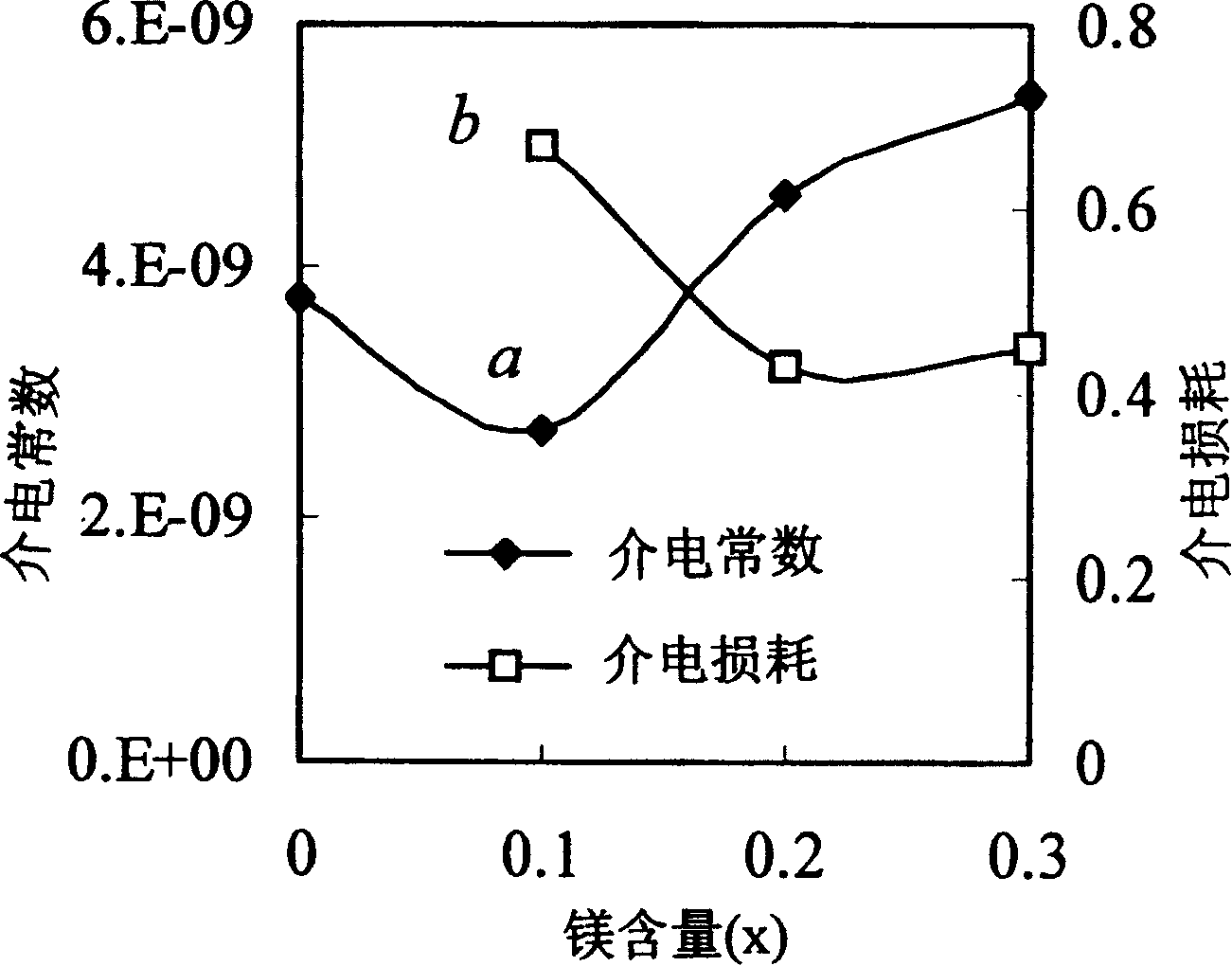

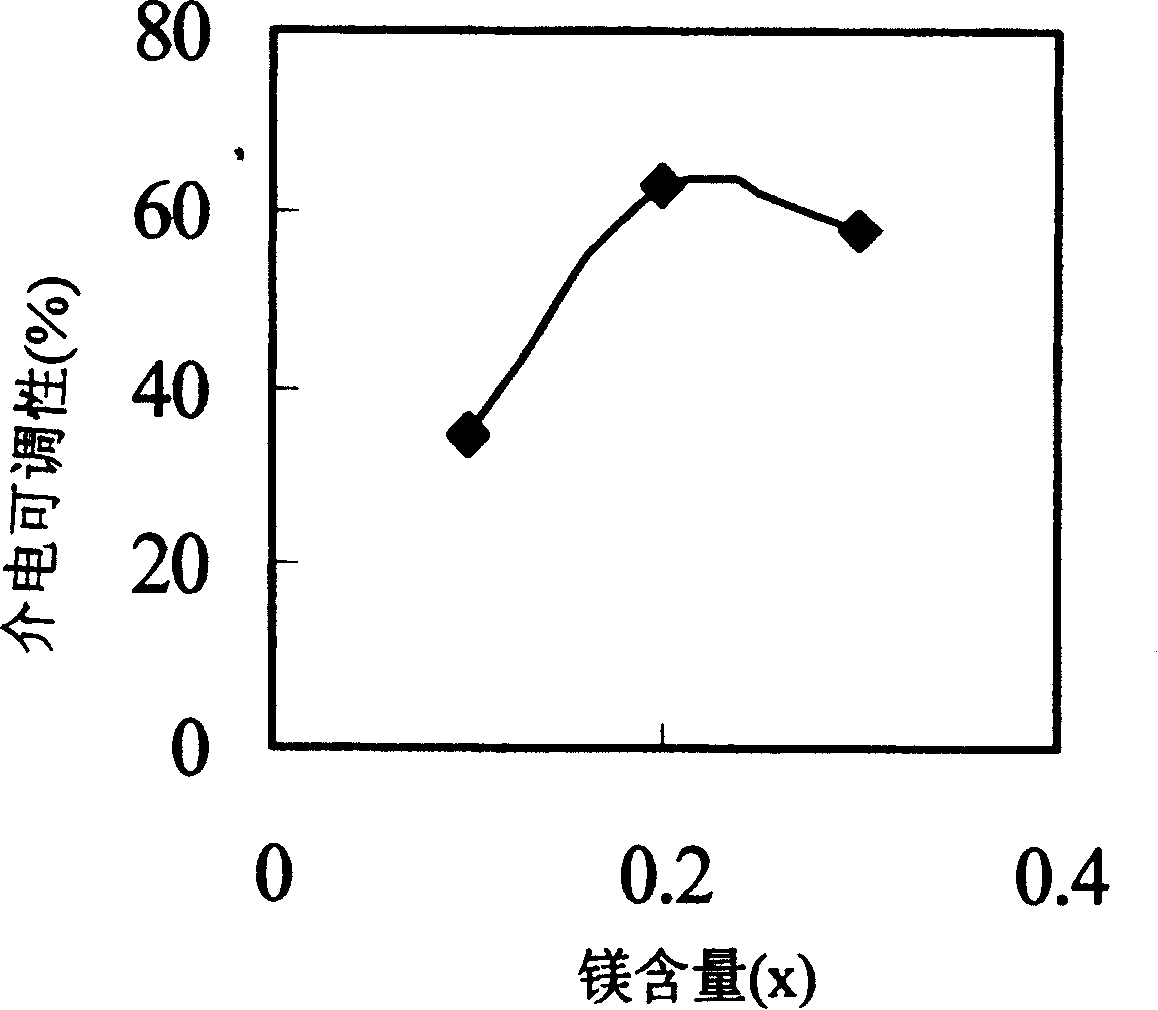

[0026] Add a small amount of deionized water to dissolve lead acetate, strontium carbonate, and magnesium carbonate into acetic acid, and heat to obtain a colorless and transparent solution; dissolve butyl titanate into ethylene glycol methyl ether, and stir until they are evenly mixed. Mix the two solutions to obtain a Pb-Sr-Mg-Ti precursor sol, in which the concentrations of the four components of Pb, Sr, Mg, and Ti are: Pb: 0.26mol / L, Sr: 0.08mol / L, Mg : 0.035mol / L, Ti: 0.315mol / L. Immerse the ITO glass slide in the prepared sol system at a constant speed (5cm / min), and place it for 15 seconds to keep the ITO glass slide in a stable state, and then lift it at the same speed (5cm / min) until the substrate is completely lifted out of the liquid surface , and then dry naturally in the air. Then put it into a high-temperature furnace, perform rapid heat treatment at 550° C. for 5 minutes, and after cooling, repeat the above operations to prepare a multilayer film. The prepared...

Embodiment 3

[0028]Add a small amount of deionized water to dissolve lead acetate, strontium carbonate, and magnesium carbonate into acetic acid, and heat to obtain a colorless and transparent solution; dissolve butyl titanate into ethylene glycol methyl ether, and stir until they are evenly mixed. Mix the two solutions to obtain a Pb-Sr-Mg-Ti precursor sol, in which the concentrations of the four components of Pb, Sr, Mg, and Ti are: Pb: 0.24mol / L, Sr: 0.10mol / L, Mg : 0.035mol / L, Ti: 0.315mol / L. Dip the Si substrate into the prepared sol system at a constant speed (5cm / min), place it for 12 seconds to keep the Si substrate in a stable state, and then lift it up at the same speed (5cm / min) until the substrate is completely lifted out of the liquid surface, and then Dry naturally in the air. Then put it into a high-temperature furnace, perform a rapid heat treatment at a temperature of 580° C. for 5 minutes, and after cooling, repeat the above operations to prepare a multilayer film. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com