Nanometer porous tungsten trioxide material and its Preparation and application

A tungsten trioxide and nanomaterial technology, which is applied in the growth of polycrystalline materials, chemical instruments and methods, crystal growth, etc., can solve the problem that the photoelectric properties of porous tungsten trioxide nanomaterials have not been better applied, and achieve good results. Photoelectrochemical properties, uniform distribution of pores, and easy manipulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

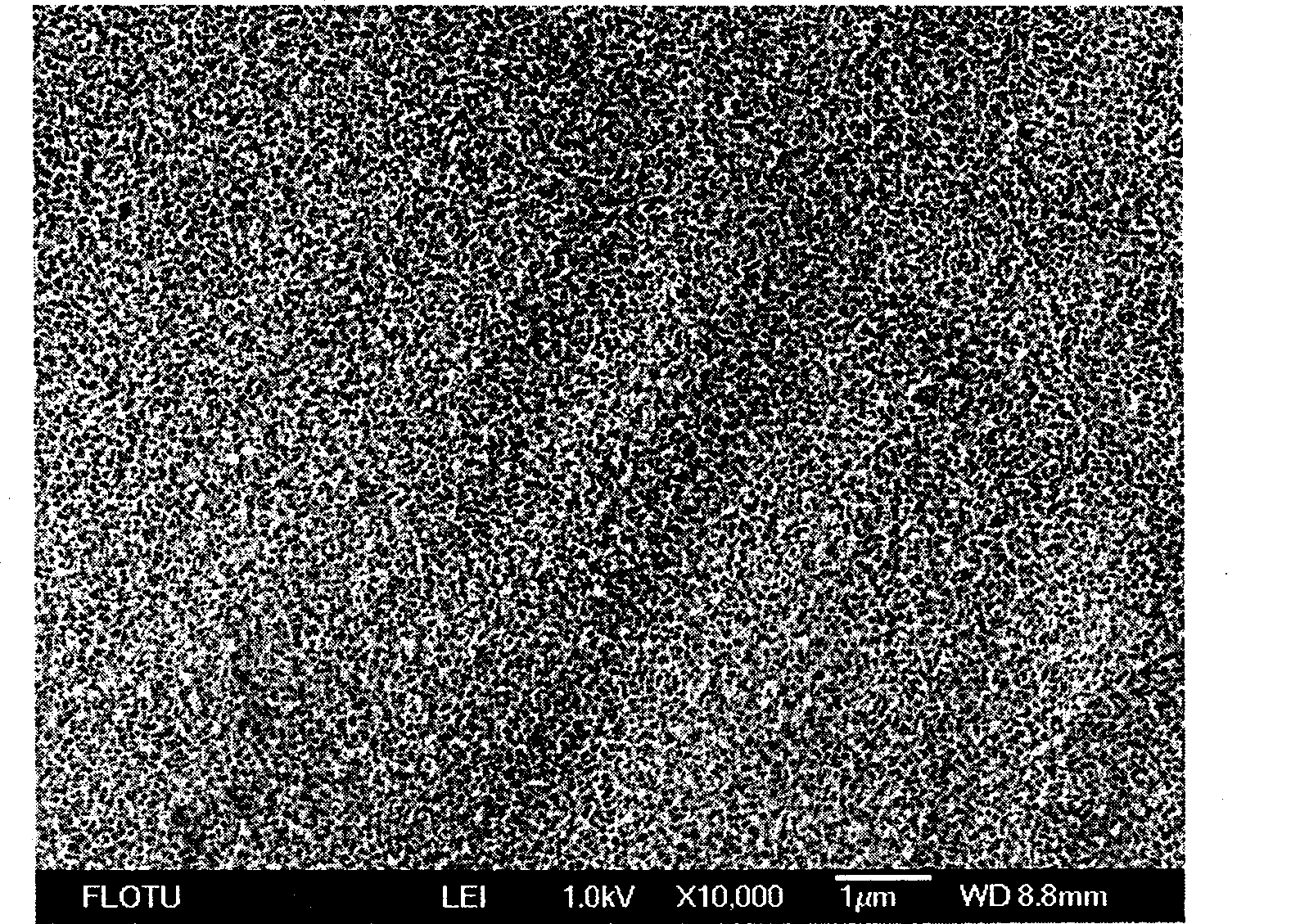

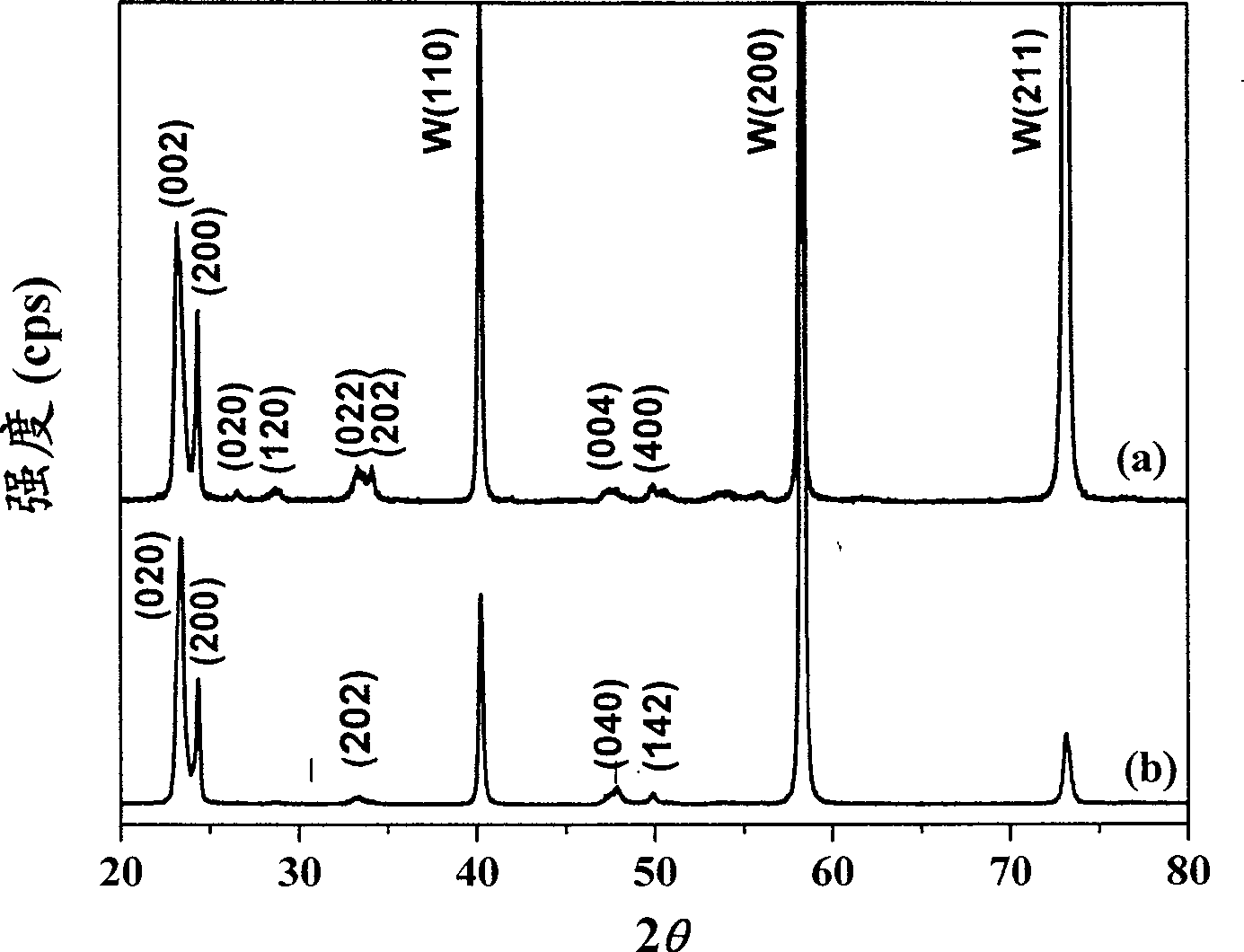

[0029]Example 1 Cut the tungsten sheet into a size of 25×50mm, and then polish it successively with sandpaper of 400 mesh, 600 mesh, 800 mesh, 1000 mesh and 1200 mesh respectively, and connect it with a wire to make an electrode; place the tungsten sheet in acetone, Ultrasonic cleaning in isopropanol, methanol and deionized water, and drying with nitrogen; mix 0.2wt% sodium fluoride (NaF) and 0.3% (V / V) hydrofluoric acid (HF) in a ratio of 1:1 After pouring into the electrolytic cell, the concentration of fluoride ion in the electrolyte is 0.11mol / L, and the concentration of hydrogen ion is 0.086mol / L. With tungsten sheet as anode and platinum electrode as cathode, control the temperature of the electrolyte at 20±1°C, first oxidize at 60V for 60 minutes, and then oxidize at 40V for 30 minutes; oxidize the tungsten sheet with diluted Soak in hydrofluoric acid for a few seconds and rinse with deionized water; finally calcined at 450°C for 4h in an oxygen atmosphere. The scannin...

Embodiment 2

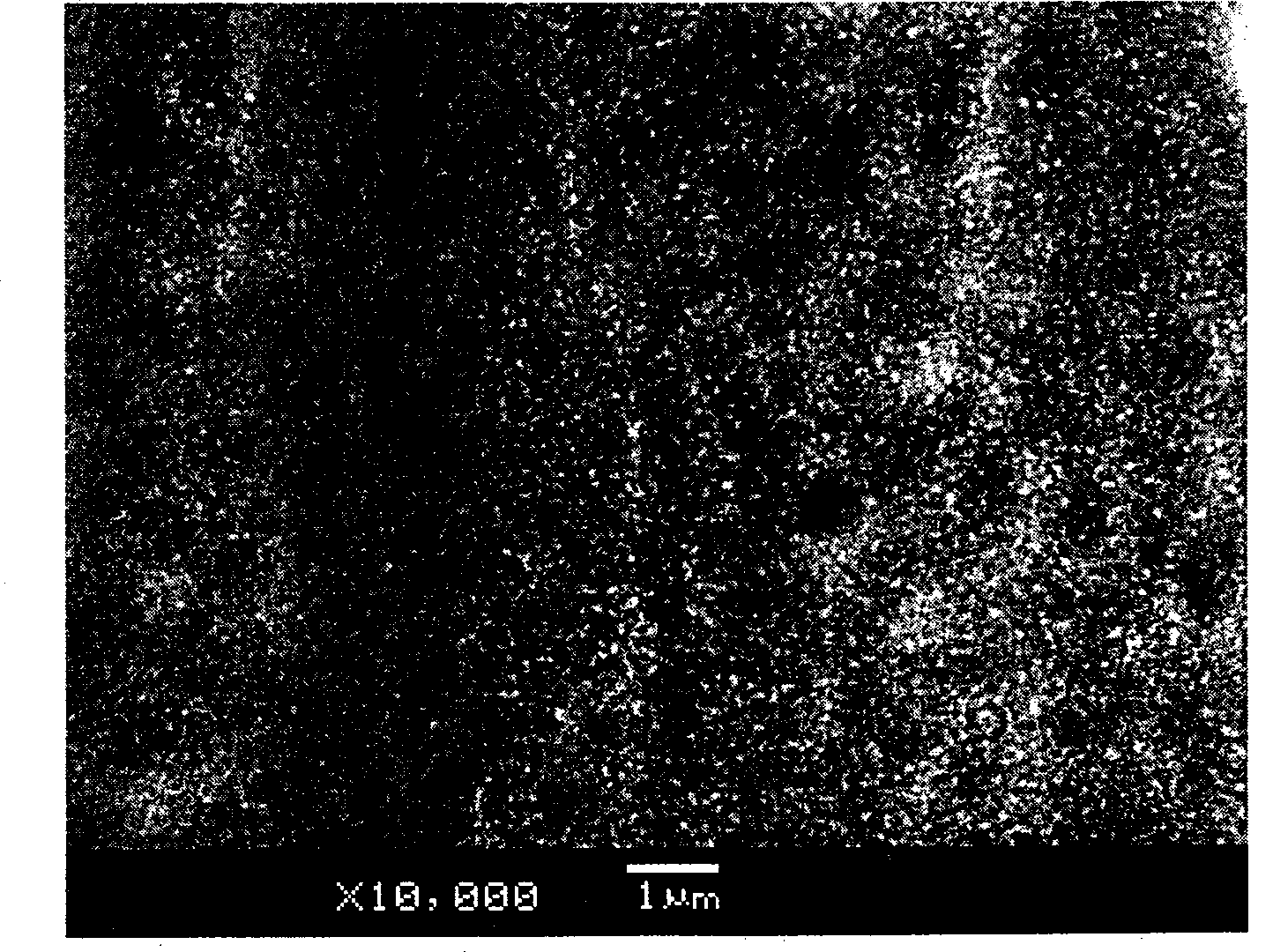

[0031] Embodiment 2 By the preparation method of the present invention of embodiment 1, just change electrolytic solution into 0.6wt% sodium fluoride (NaF) and 0.5mol / L sulfuric acid (H 2 SO 4 ) in a ratio of 1:1, that is, the concentration of fluoride ions is 0.07mol / L, and the concentration of hydrogen ions is 0.5mol / L. Porous tungsten trioxide nanomaterials with a self-assembled structure were obtained, the average pore diameter was about 100 nm, and the crystal structure was the same as in Example 1.

Embodiment 3

[0032] Embodiment 3 According to the preparation method of the present invention of embodiment 1, just change electrolytic solution into 1.0wt% ammonium fluoride (NH 4 F) Mix with 0.5mol / L hydrochloric acid (HCl) at a ratio of 1:1, that is, the concentration of fluoride ion is 0.24mol / L, and the concentration of hydrogen ion is 0.25mol / L. Porous tungsten trioxide nanomaterials with a self-assembled structure were obtained, the average pore diameter was about 120 nm, and the crystal structure was the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com