Ultrasonic microvesicle as immuno adjuvant and vaccine carrier

A technology of ultrasonic microbubbles and vaccine carriers, applied in the field of biomedical engineering, can solve the problems that it is difficult to meet the needs of the development of new peptide vaccines and fail to stimulate immune responses, achieve safe repeatability, improve nucleic acid expression levels, and target good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

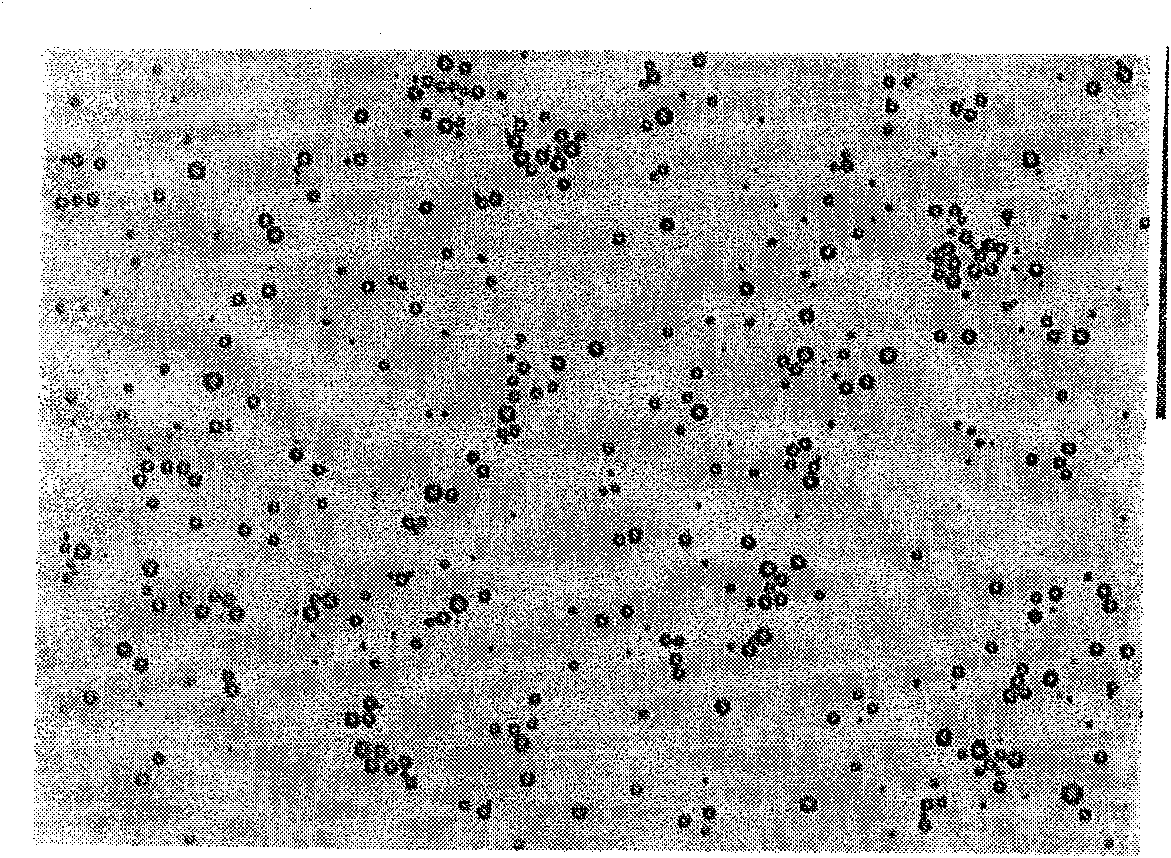

[0017] Example 1: Preparation of Surfactant-like Microbubbles

[0018] Mix the surfactant Span60; Tween 80 in a ratio of 1:1, and at the same time use NaCl:KCl:Na 2 HPO 4 :KH 2 PO 4According to the mass ratio of 200:30:5:1, add 100ml of deionized water, and use NaOH to adjust the pH value of the mixture to 7.36, which is used as the medium; add 100ml of the medium into the mixture of Span60 and Tween 80 , the mixture obtained above was heated on a magnetic stirrer, the temperature was heated to 120 ° C, and the time was 10 minutes, and it was fully mixed to make it a milky suspension system; At the same time, add 0.6ml of perfluoropropane gas at a rate of 0.5ml / s; place the probe of the vibrometer at 0.5-2.0cm below the liquid surface for acoustic vibration treatment, and vibrate at 30% of the maximum output power for 3 minutes. The emulsified mixed solution after sonication is divided into 3 layers after standing for 35 minutes, and the middle layer is taken out and dilut...

example 2

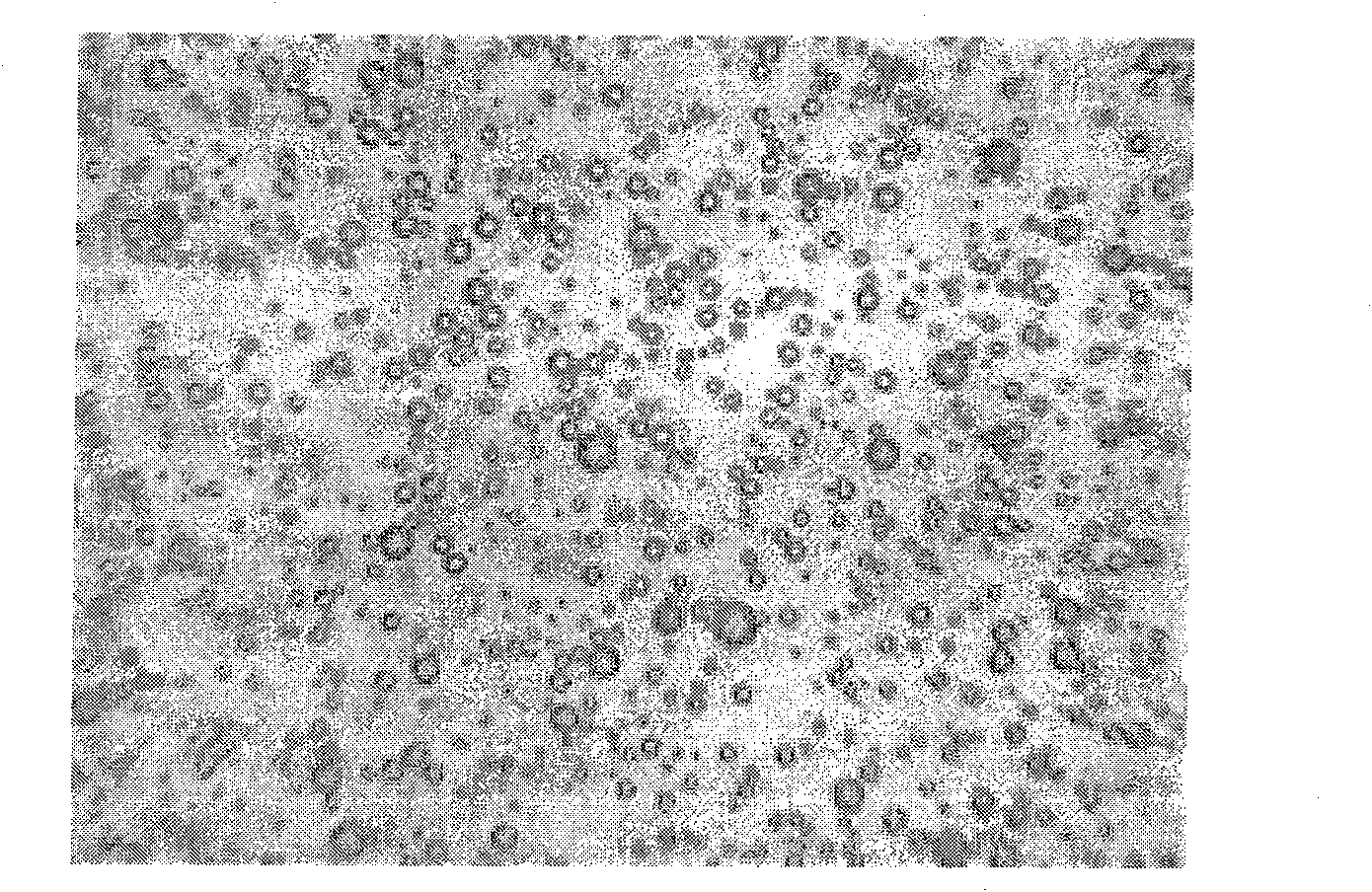

[0019] Example 2: Preparation of Lipid Microvesicles

[0020] Lecithin, cholesterol, polyethylene glycol stearyl ethanolamine were dissolved in chloroform at a mass ratio of 1:3:3, and evaporated in a rotary vacuum to form a film; 0.9% sodium chloride solution, propylene glycol and glycerin (0.9% chlorine Sodium chloride solution: propylene glycol: glycerin = 8:1:1), shake to wash the membrane to form a liposome suspension. Freeze overnight. After thawing, vibrate for 80s with a sonicator at 30% of the maximum output power, and at the same time slowly fill in 0.6ml of perfluoropropane gas below through the tee tube to form lipid fluorocarbon microbubbles (such as figure 2 ).

example 3

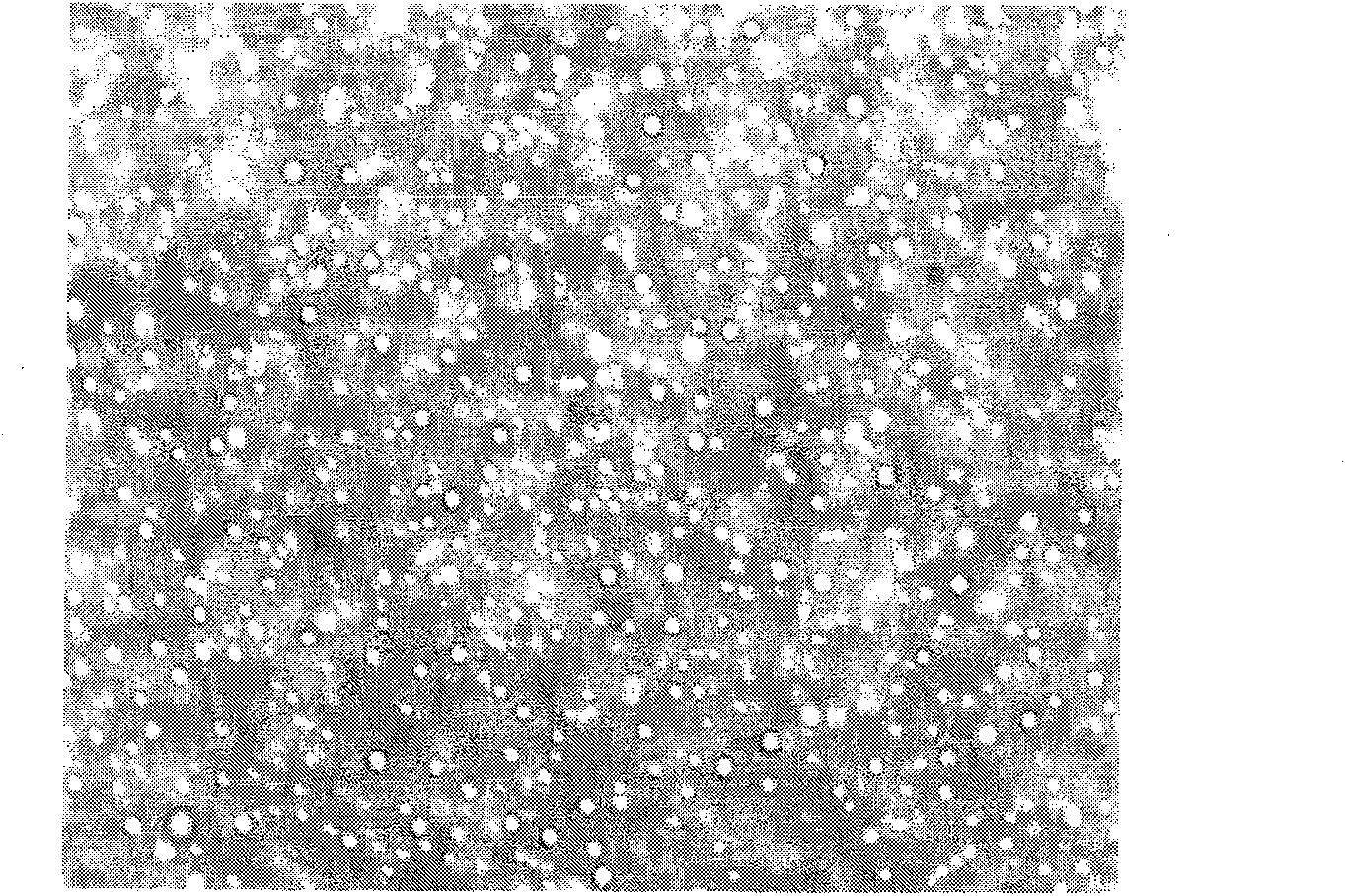

[0021] Example 3: Preparation of polymer material-polylactic acid / glycolic acid (PLGA) microbubbles

[0022] Add 0.1g of camphor into 20ml of dichloromethane, stir fully to make it completely dissolved; add 1.0g of high molecular material polylactic acid / glycolic acid polymer (PLGA) into the above solution, stir until it is completely dissolved, and then add 5% After 3ml of ammonium chloride is added, vibrate for 40s with a vibrator at 30% of the maximum output power to form a milky white emulsion; add the emulsion to 3% polyvinyl alcohol and homogenize it for 5 minutes, then add 2% isopropanol solution, stirred with a magnetic stirrer at room temperature for 2-5 hours, centrifuged at a high speed for 5 minutes (3000-5000 rpm), repeated 3 times; added 5% mannitol and fully mixed into a milky white solution to obtain PLGA microbubbles (such as image 3 )

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com