Method for preparing resin used for metal corsslinking molecular film-forming bi-component water carpentry paint

A water-based wood paint and metal cross-linking technology, applied in coatings, liquid spraying devices, spraying devices, etc., can solve the problems of poor storage stability, cross-linking density and low mechanical strength of the paint film, and achieve low production costs and fullness Good degree and easy sanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

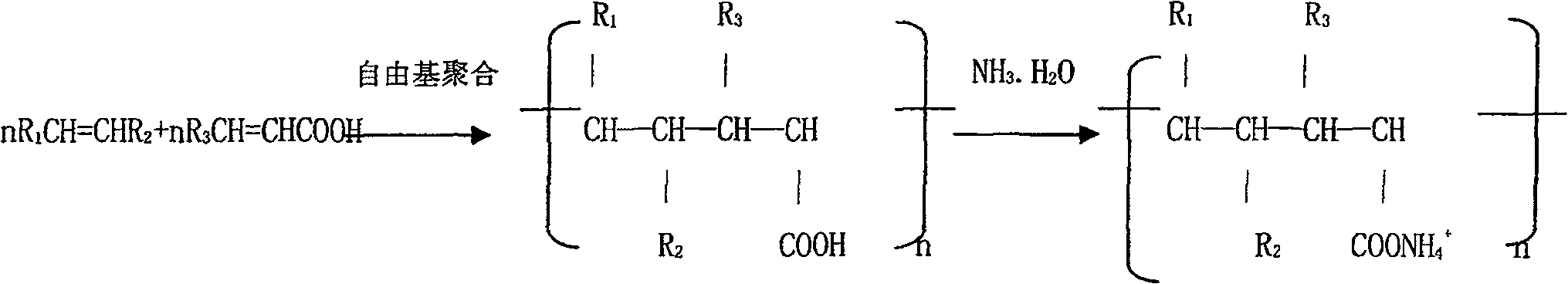

Method used

Image

Examples

Embodiment 1

[0057] The monomer composition of present embodiment resin copolymer is as follows:

[0058] components

Percentage (weight), %

10.18

9.82

20.00

[0059] 10% by weight of N-methylpyrrolidone was added to the reaction flask, protected by nitrogen gas, stirred, heated to 140°C, and the above monomer mixture, 2% by weight of benzoyl peroxide and 1% by weight of 2-mercapto Add ethanol dropwise into the bottle for 4 hours, then react at 150°C for 4h, and carry out vacuum distillation on the obtained product, then cool down to 60°C, add 10% by weight of ammonia water and 37% by weight of tap water, and quickly Stir for 3h.

[0060] The water-based resin obtained in this embodiment has the following properties:

[0061] project

technical indicators

Exterior

Transparent homogeneous solution

solid content

39.5%

Volatile Organic Comp...

Embodiment 2

[0065] The copolymer composition of present embodiment resin is as follows:

[0066] components

Percentage (weight), %

25.22

2-Ethylhexyl Acrylate,

17.31

7.47

acrylic

5.00

[0067] 5% by weight of isopropanol and 0.5% by weight of antioxidants were added to the reaction flask, stirred, heated to 70 ° C, the above-mentioned monomer mixture and 0.5% by weight of azobisisobutyronitrile and 2% by weight of Dodecyl mercaptan was added dropwise into the bottle for 1 hour, and then reacted at 70°C for 1 hour. After the product is distilled under reduced pressure, the temperature is lowered to below 10° C., 0.5% by weight of ethylenediamine and 36.5% by weight of distilled water are added, and the mixture is rapidly stirred for 0.5 h.

[0068] The resin obtained in this embodiment has the following properties:

[0069] project

Embodiment 3

[0071] The copolymer composition of present embodiment resin is as follows:

[0072] components

Percentage (weight), %

6.29

Decyl acrylate

27.21

1.50

12.50

[0073] Add 7.5% by weight ethylene glycol monobutyl ether and 0.25% by weight antioxidant to the reaction flask, stir, and heat to 105°C, dropwise add the above monomer mixture and 1.25% by weight of azobisisobutyronitrile In the bottle, the dropwise addition time is 2.5h, and then react at 110°C for 2.5h. After the product was distilled under reduced pressure, the temperature was lowered to below 35° C., 5.25% by weight of ethanolamine and 38.25% by weight of deionized water were added, and the mixture was stirred rapidly for 1.75 hours.

[0074] The resin obtained in this embodiment has the following properties:

[0075] project

technical indicators

Exterior

Trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com