Water-soluble chitosan microsphere for carrying medicament and preparation thereof

A water-soluble chitosan, drug-loading technology, applied in pharmaceutical formulations, medical preparations with inactive ingredients, bulk delivery, etc., can solve the problem of poor strength, easy drug elution, and low drug encapsulation rate. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

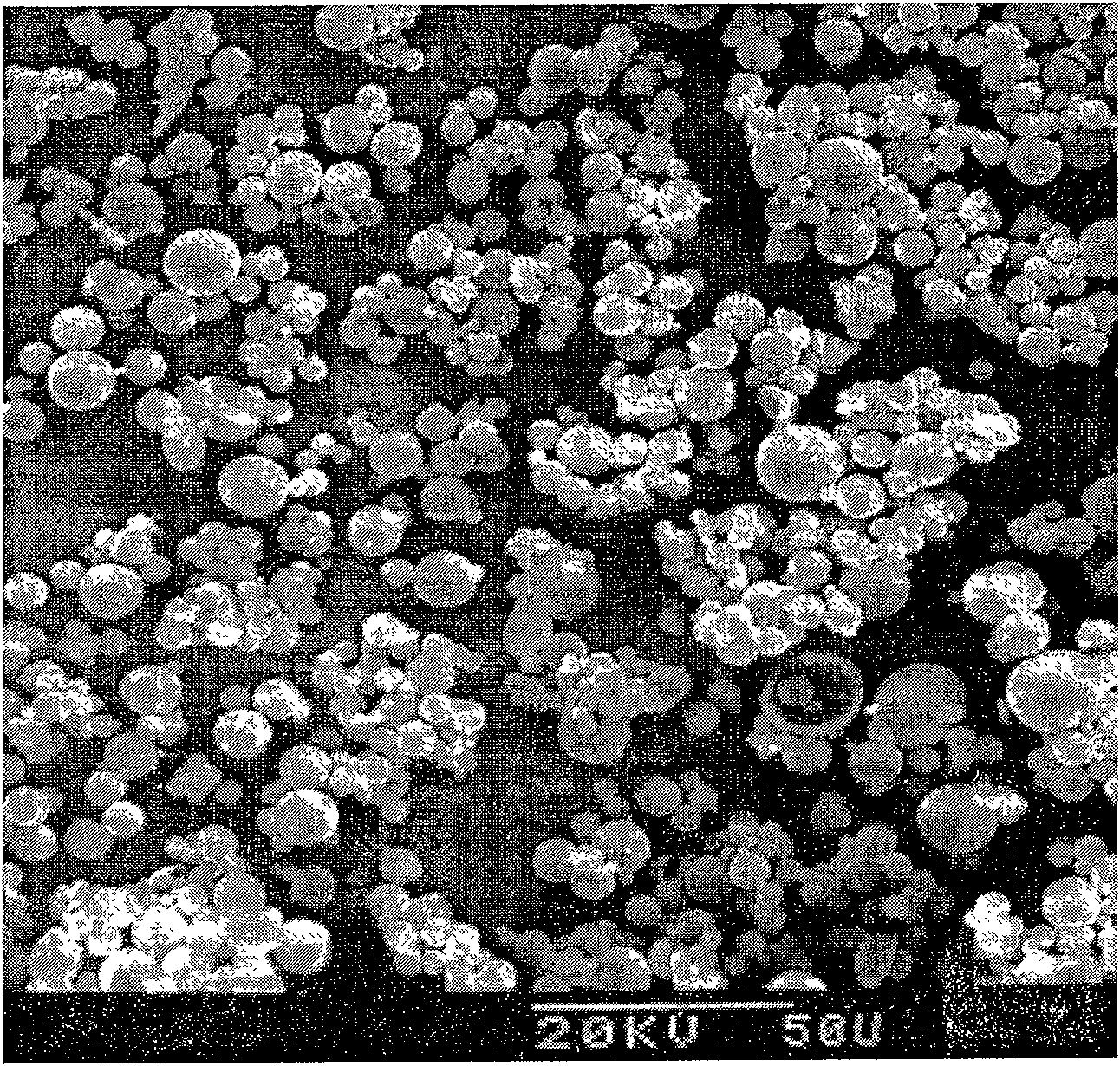

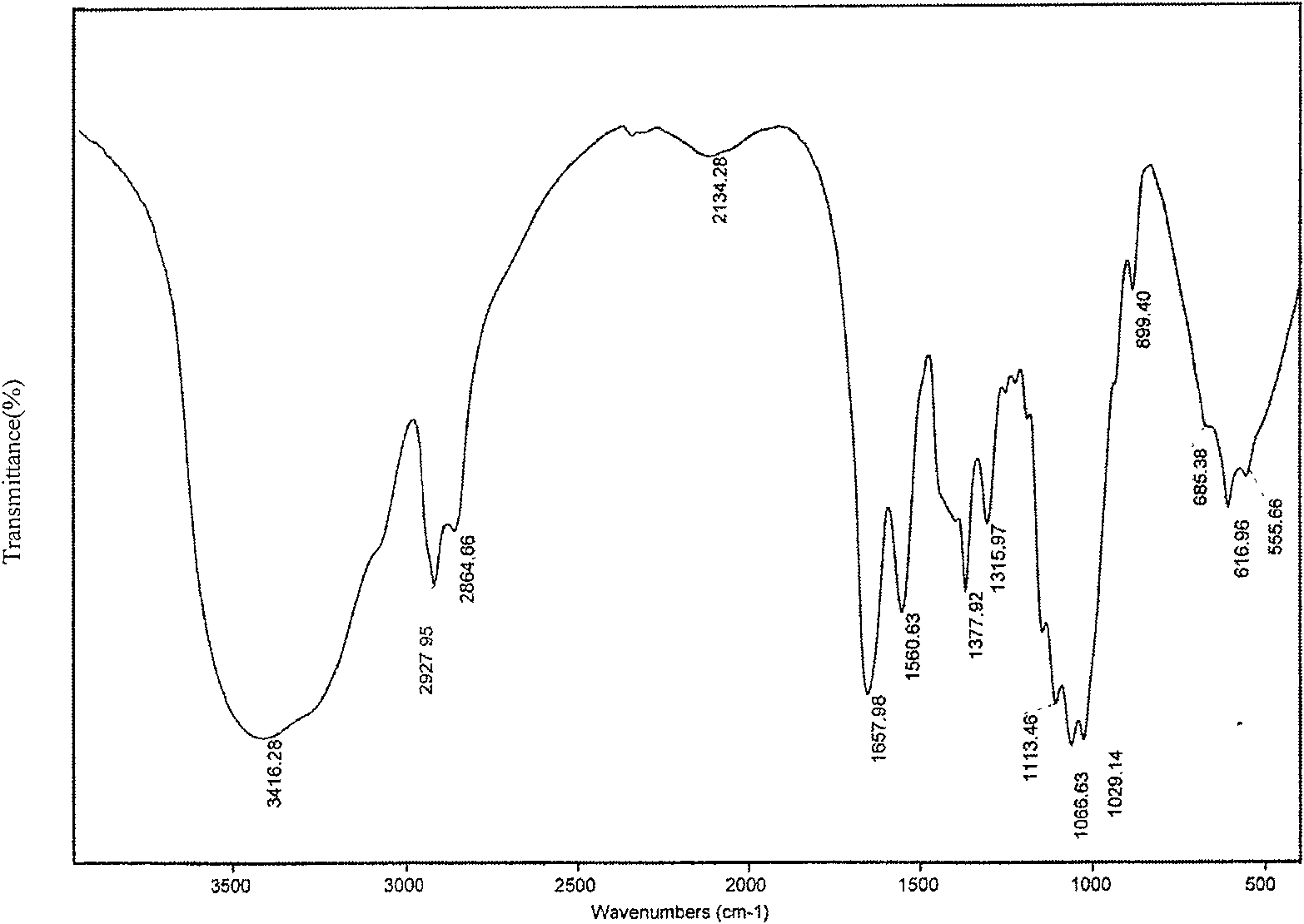

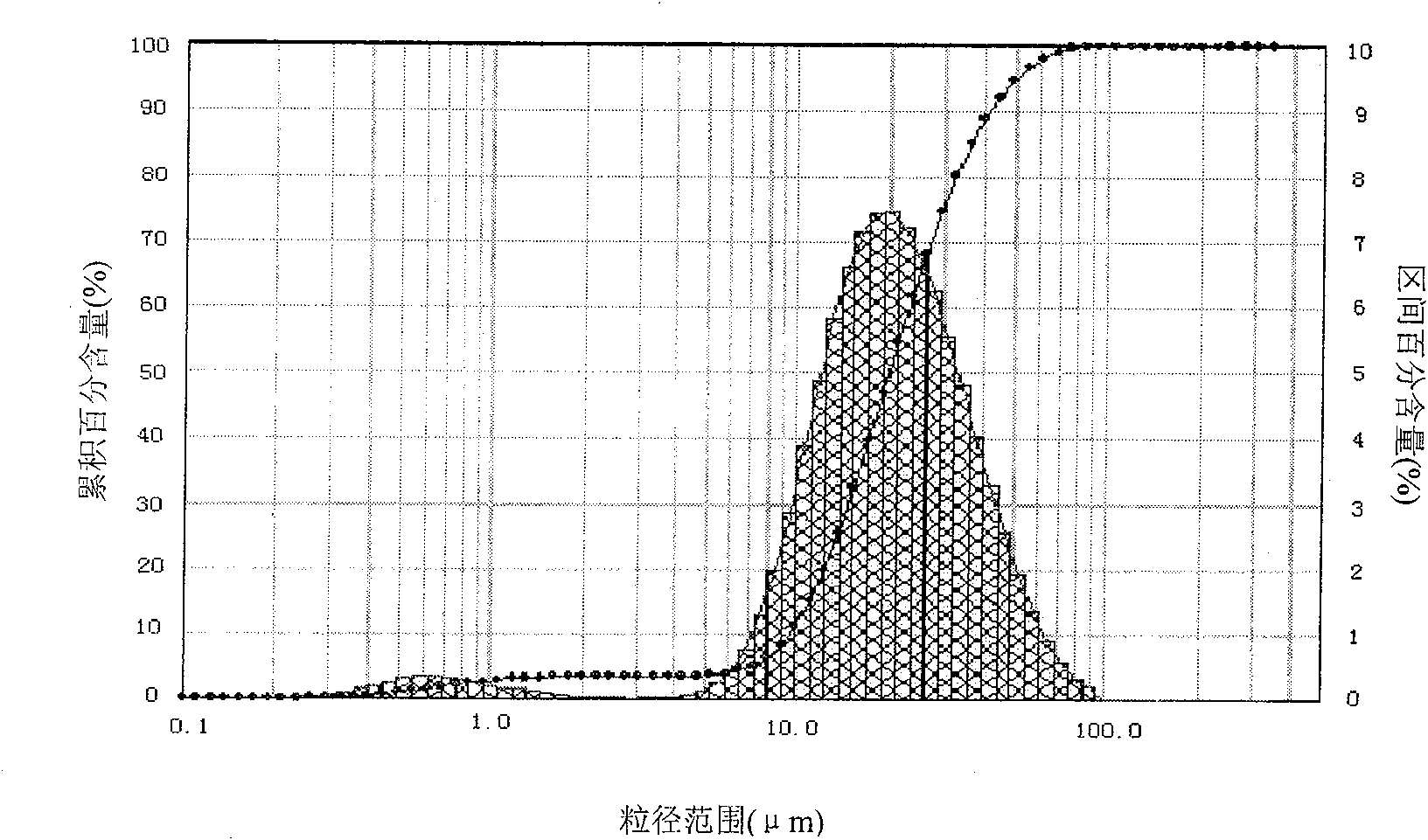

[0030] The deacetylation degree is 95% chitosan 2g, is configured in the acetic acid solution of 2wt% 2wt% chitosan acetic acid solution 100g in concentration, joins in 100g methanol, drips 0.64g acetic anhydride under stirring, stand Aging for 24 hours, under the condition of stirring at 600 rpm, adding to 500 g of 10wt% KOH absolute ethanol solution, filtering, washing with absolute ethanol until neutral, drying and grinding through a 200-mesh sieve, and taking the undersize It is the raw material of water-soluble chitosan.

[0031] Dissolve 2 g of water-soluble chitosan in 48 g of water to obtain 50 g of water-soluble chitosan solution, get 25 g of water-soluble chitosan solution, and uniformly disperse 0.4 g of the model drug rifampin in it as the water phase; 100 g of liquid paraffin , 1.7g Span80 and 0.3g Tween80 were stirred together uniformly as the oil phase; the water phase was added to the oil phase, and stirred at 1800 rpm for 30 minutes to obtain an emulsion.

[...

Embodiment 2

[0034] 2 g of chitosan with a degree of deacetylation of 90% is configured into 200 g of 1 wt % chitosan acetic acid solution in 2 wt % acetic acid solution, added to 150 g of methanol, and 0.61 g of acetic anhydride is added dropwise under stirring, and left to stand Aging for 24 hours, adding to 700 g of 10wt% KOH absolute ethanol solution with stirring at 500 rpm, filtering, washing with absolute ethanol until neutral, drying and grinding through a 200-mesh sieve, and taking the undersize It is the raw material of water-soluble chitosan.

[0035] 2g of water-soluble chitosan was dissolved in 48g of water to obtain 50g of water-soluble chitosan solution, 25g of water-soluble chitosan solution was taken, and 0.2g of cisplatin as the model drug was uniformly dispersed therein as the water phase; 120g of olive oil, Stir 1.8g of Span60 and 0.2g of Tween80 together to form an oil phase; add the water phase to the oil phase, and stir at 1500 rpm for 30 minutes to obtain an emulsio...

Embodiment 3

[0038] 2g of chitosan with a deacetylation degree of 85% is configured into 100g of 2wt% chitosan acetic acid solution in a 2wt% acetic acid solution, added to 100g of methanol, and 0.58g of acetic anhydride is added dropwise under stirring, and left to stand Aging for 24 hours, under the condition of stirring at 500 rev / min, add it to 1000 g of 5wt% KOH absolute ethanol solution, filter, wash with absolute ethanol until neutral, dry and finely pass through a 200-mesh sieve, and take the undersize It is the raw material of water-soluble chitosan.

[0039] Dissolve 2 g of water-soluble chitosan in 48 g of water to obtain 50 g of water-soluble chitosan solution, take 27.8 g of water-soluble chitosan solution, and uniformly disperse 0.2 g of the model drug secretin in it as the water phase; 150 g of sunflower seeds Stir oil, 1.1g Span65 and 0.4g Tween40 together to form an oil phase; add the water phase to the oil phase, and stir at 1600 rpm for 25 minutes to obtain an emulsion. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com