Method of preparing waterless lithium terafluoroborate

A technology of lithium tetrafluoroborate and tetrafluoroborate, which is applied in the directions of tetrafluoroborate and boron halide compounds, can solve the problems of reducing the purity of lithium tetrafluoroborate, affecting the effect of dehydration, and increasing costs, achieving complete crystal form and improving The effect of purity, low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

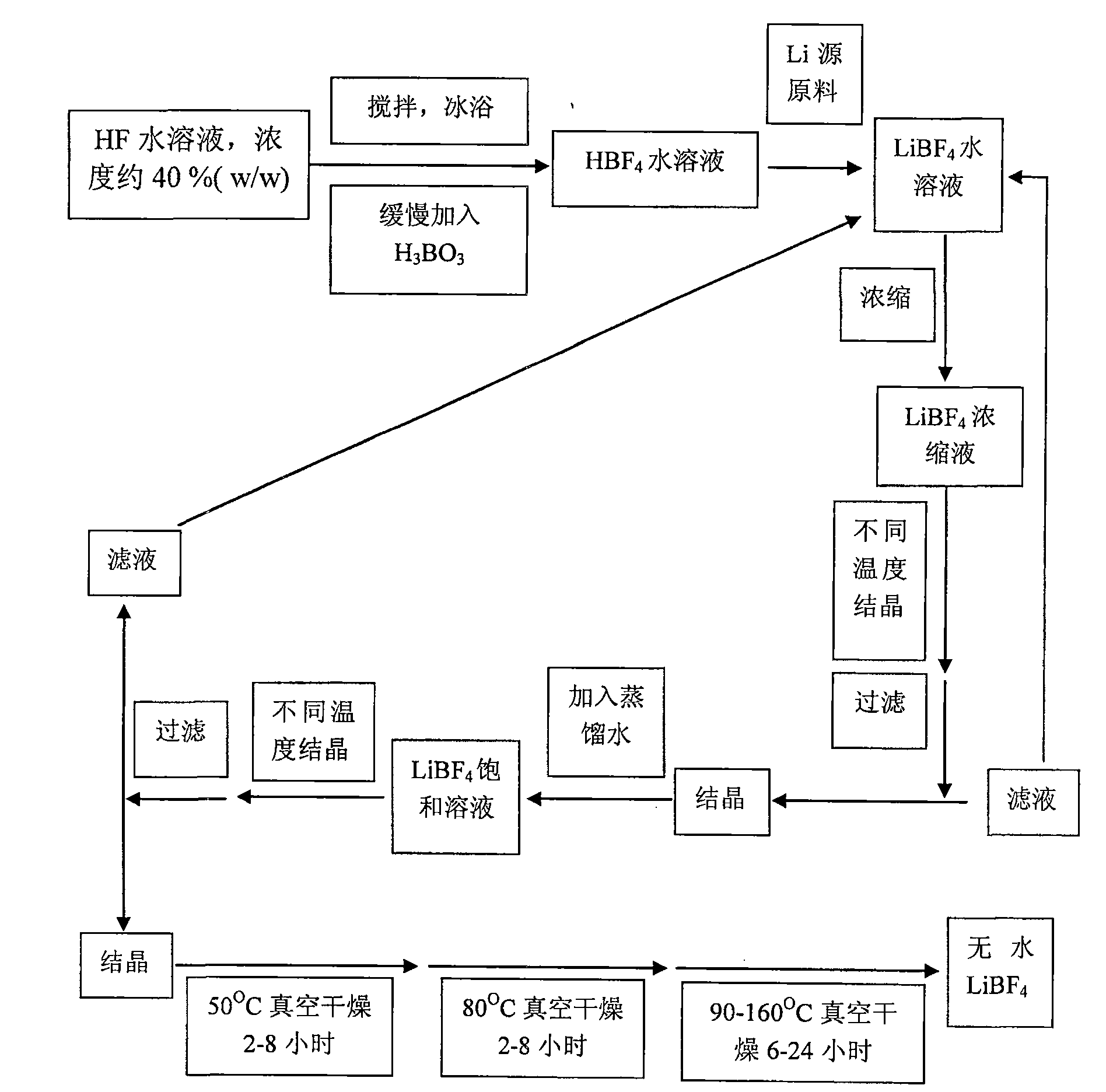

Method used

Image

Examples

Embodiment 1

[0021] Weigh the mass fraction to be about 40% (the analytically pure hydrofluoric acid purchased is calibrated by the national standard GB620-93, and its mass fraction is about 40.87%. When hydrofluoric acid is used in foreign literature, it is generally said that the mass fraction is 48% %, the same below), put 209g of hydrogen fluoride aqueous solution into an ice bath, and stir with a magnetic stirrer. After 10 minutes, slowly add 66.1g of boric acid, and finish adding in about 50 minutes. Continue to stir for 30 minutes after the addition, then slowly add 40.6g of lithium carbonate to the above mixed solution, finish adding in about 30 minutes, filter, and concentrate the filtrate under an infrared lamp to make the content of lithium tetrafluoroborate about 70% . Put the concentrated solution in a constant temperature water bath at about 40°C, filter it after 12 hours, and return the filtrate to the mother liquor. Dissolve the solid phase with an appropriate amount of di...

Embodiment 2

[0023] Weigh 104.4g of hydrogen fluoride aqueous solution with a mass fraction of about 40%, put it in an ice bath, and stir it with a magnetic stirrer. After 10 minutes, slowly add 33g of boric acid, and finish adding in about 50 minutes. Continue to stir for 30 minutes after adding, then slowly add 20.3g of lithium carbonate to the above mixed solution, finish adding in about 30 minutes, filter, and concentrate the filtrate under an infrared lamp to make the content of lithium tetrafluoroborate about 70% . Put the concentrated solution in a constant temperature water bath at about 5°C, filter after 2 hours, and return the filtrate to the mother liquor. The solid phase was placed in a vacuum oven. Dry at about 50°C and 560mmHg for 5 hours, then raise the temperature to about 80°C, continue to dry for 5 hours, take the solid out of the vacuum drying oven, grind it, and then put it in the vacuum drying oven again, and dry it at about 140°C and 560mmHg for 10 hours hour, the w...

Embodiment 3

[0025] Weigh 105g of hydrogen fluoride aqueous solution with a mass fraction of about 40%, put it in an ice bath, and stir with a magnetic stirrer. After 10 minutes, slowly add 33g of boric acid, and finish adding in about 50 minutes. Stirring was continued for 30 minutes after the addition, and then 20.9gLiOH·H 2 O was slowly added to the above mixed solution, and the addition was completed in about 30 minutes, filtered, and the filtrate was concentrated under an infrared lamp, so that the content of lithium tetrafluoroborate was about 70%. Put the concentrated solution in a constant temperature water bath at about 40°C, filter it after 12 hours, and return the filtrate to the mother liquor. Dissolve the solid phase with an appropriate amount of distilled water to completely dissolve the crystals, and place the solution again in a constant temperature water bath at about 30°C. Filter after 72 hours, return the filtrate to the mother liquor, and put the solid phase into a vac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com