Catalyst for synthesizing melamine and preparing method

A melamine and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic chemistry, etc., can solve the problems of harsh reaction conditions, high investment cost, long reaction process, etc., and achieve short induction period and high catalyst strength. , the effect of high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

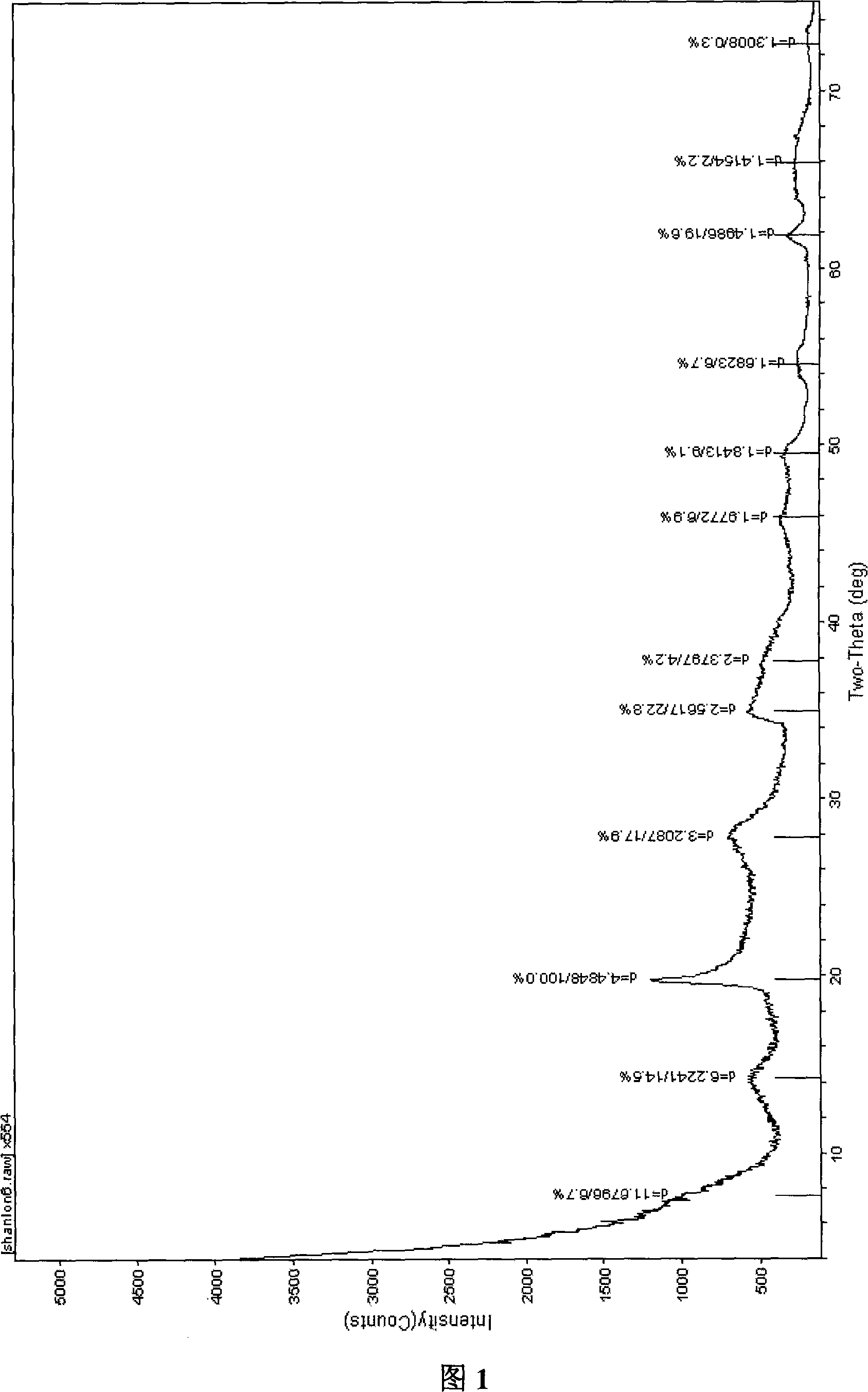

[0028] Add commercially available aluminum silicate [Hz][Al 2-x h x ][Si 4-y al y ]O 12 Wherein x=0.15, y=0.07, z=0.22, 70kg mix well, then add 3% dilute nitric acid 65kg, carry out kneading, knead about 40 minutes, extrude in extruder after, extruding pressure is 5Mpa, bar diameter 3mm, strips were dried at 105°C, crushed by a crusher, sieved through a 60-120 mesh vibrating sieve, and activated at 480°C for 3 hours to obtain a melamine catalyst. The obtained catalyst stack has a specific gravity of 0.66g / ml and a specific surface area of 215.8m 2 / g, pore volume 0.305ml / g, abrasion 0.9%. Description of drawings: Fig. 1 is the X-ray diffraction spectrogram of obtained catalyst. The application results of this catalyst on a 1000t / a melamine industrial production plant: when the reaction temperature is 390°C, and the urea feeding amount is 71.5kg / tCat×, the total feeding amount of urea is 198.5 tons, melamine is obtained 63.016 tons, and the reaction conversion rate is 3....

Embodiment 2

[0030] With commercially available aluminum silicon oxide [Hz] [Al 2-x h x ][Si 4-y al y ]O 12 Wherein x=0.15, y=0.07, z=0.22, 700g, add 300g of commercially available pseudo-thin alumina and mix evenly, then add 3% dilute phosphoric acid and knead, the consumption of dilute phosphoric acid is 700ml; knead about 40 minutes, then Extrude the rod in the extruder, the pressure is 5Mpa, the diameter of the rod is 3mm. The strips were dried at 105°C, crushed by a crusher, sieved through a 60-120 mesh vibrating sieve, and activated at 480°C for 3 hours to obtain a melamine catalyst. The obtained catalyst: bulk specific gravity 0.73g / ml, specific surface 182.7m 2 / g, pore volume 0.309ml / g, abrasion 1.62%. The evaluation result of the agent when the reaction temperature is 370°C on the small-scale fluidized bed activity evaluation device: when the urea dosage is 160.4g / kgCat×, the reaction conversion rate is 3.14g urea / g melamine. The results are shown in Table 1 and Table 2. ...

Embodiment 3

[0032] Use commercially available carbonized dry rubber powder 400g, add commercially available aluminum silicon oxide 600g, [Hz][Al 2-x h x ][Si 4-y al y ]O 12 Among them, x=0.16, y=0.08, z=0.24 and 30g of safflower powder are mixed evenly, and then kneaded by adding water, the amount of water added is 700g, kneaded for about 40 minutes, and the pressure is 5Mpa, extruded in the extruder, the diameter of the strip 3-5mm. The strips are dried at 100°C, crushed by a crusher, sieved through a 60-120 mesh vibrating sieve, activated at 500°C for 2.5 hours to obtain a melamine catalyst. The obtained catalyst: bulk specific gravity 0.69g / ml, specific surface 201.5m 2 / g, pore volume 0.321ml / g, abrasion 1.2%. The evaluation result of the catalyst when the reaction temperature is 370° C. on a small-scale fluidized bed activity evaluation device: when the urea dosage is 135.4 g / kgCat×, the reaction conversion rate is 3.26 g urea / g melamine. The results are shown in Table 1 and T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com