Method for preparing L-arabinose

A technology of arabinose and supernatant, which is applied in the direction of fermentation, etc., can solve the problems of low production efficiency, no indication of refining and purification, and high production cost, and achieve the effects of improving production efficiency, reducing filtration difficulty, and reducing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

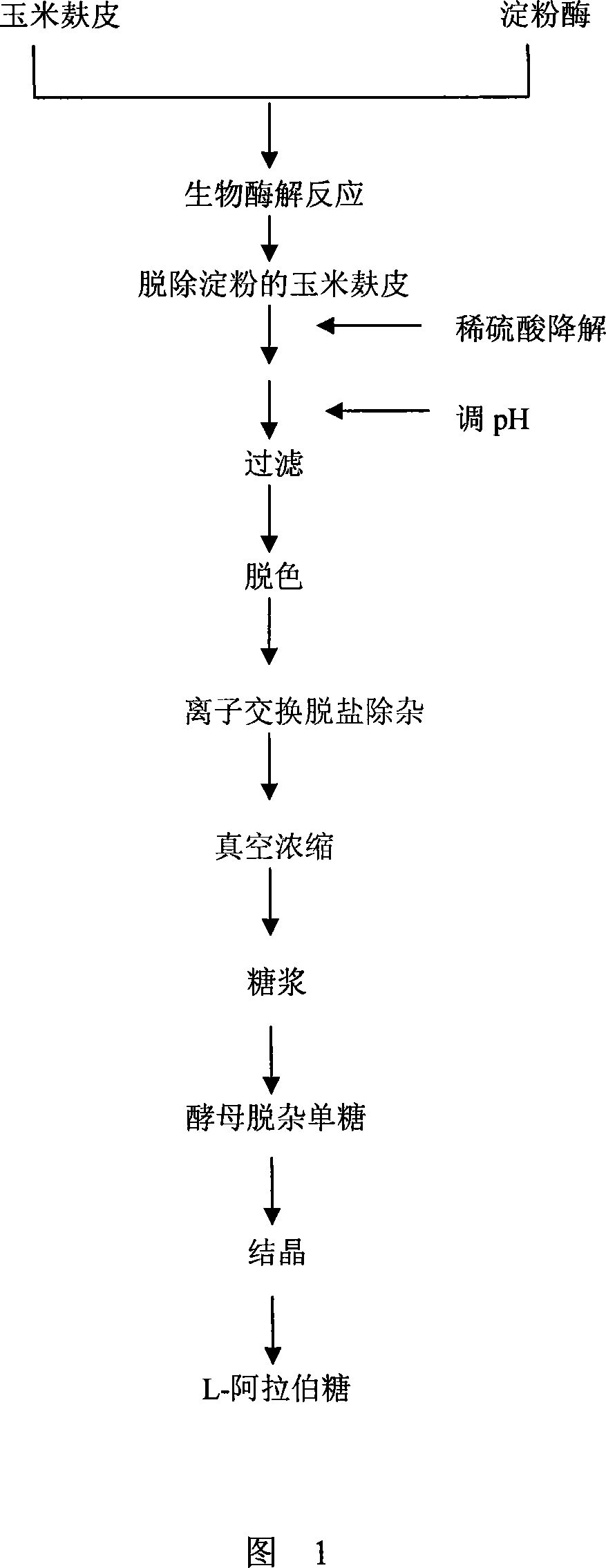

Image

Examples

Embodiment 1

[0028] Embodiment 1, prepare L-arabinose with the method of the present invention

[0029] Take by weighing 100kg of corn bran after pulverizing, add water and allocate to 5% corn bran material, add 2kg amylase (amylase is made up of α-amylase and β-amylase that the weight and number ratio is 1: 1), 35 Stir the reaction at ℃ for 12h, and filter by centrifugation. The filter cake is washed 2-3 times with water, and the water consumption for each washing is 200L. Add 2000L 1.5% sulfuric acid solution to the reaction kettle containing the above filter cake, reflux at 100°C for 4 hours, stop the reaction, adjust the pH of the reaction solution to 4.5 with calcium carbonate with a pH value of 7, filter, and use 200L 2% ammonia water Wash the filter cake 2 times. Combine the filtrates, add activated carbon with a mass percentage of 1% of the filtrate, decolorize at 100°C for 45 minutes, and filter with a plate frame. Gained filtrate passes through 732 cation exchange resin-721 an...

Embodiment 2

[0030] Embodiment 2, prepare L-arabinose with the method of the present invention

[0031] Take by weighing 150kg of corn bran after pulverizing, add water and allocate into 4% corn bran material, add 2kg amylase (amylase is made up of α-amylase and β-amylase that the weight and number ratio is 0.5: 1), 45 Stir the reaction at ℃ for 8h, and filter by centrifugation. The filter cake is washed 2-3 times with water, and the water consumption for each washing is 220L. Add 2500L 1% hydrochloric acid solution to the reaction kettle containing the above filter cake, reflux at 110°C for 8 hours, stop the reaction, adjust the pH of the reaction solution to 3.5 with calcium hydroxide with a pH value of 8, filter, and use 250L 2% Wash the filter cake with ammonia water 2 times. Combine the filtrates. Add activated carbon with a mass percentage of 2% of the filtrate, decolorize at 105°C for 60 minutes, and filter with a plate and frame filter. Gained filtrate passes through 732 cation...

Embodiment 3

[0032] Embodiment 3, prepare L-arabinose with the method of the present invention

[0033]Take by weighing 100kg of corn bran after pulverizing, add water and allocate to 6% corn bran material, add 3kg amylase (amylase is made up of α-amylase and β-amylase that the weight and number ratio is 1.5:1), 40 Stir the reaction at around ℃ for 12h, and filter by centrifugation. The filter cake is washed 2-3 times with water, and the water consumption for each washing is 200L. Add 2000L 5% acetic acid solution to the reaction kettle containing the above filter cake, reflux at 110°C for 6 hours, stop the reaction, adjust the pH of the reaction solution to 5.5 with sodium hydroxide with a pH value of 8, filter, and use 200L 2% Wash the filter cake with ammonia water 2 times. Combine the filtrates. Add activated carbon with a mass percentage of 1.5% of the filtrate, decolorize at 100°C for 90 minutes, and filter with a plate and frame filter. Gained filtrate passes through 732 cation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com