Novel method for manufacturing nano gallium acid magnesium

A kind of gallium acid and nanotechnology, applied in the direction of nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems that cannot meet the actual needs, the precursors are difficult to wash, and easy to form hard agglomerates, so as to meet the needs of green production and avoid products The effect of sintering and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1 (with urea as organic fuel):

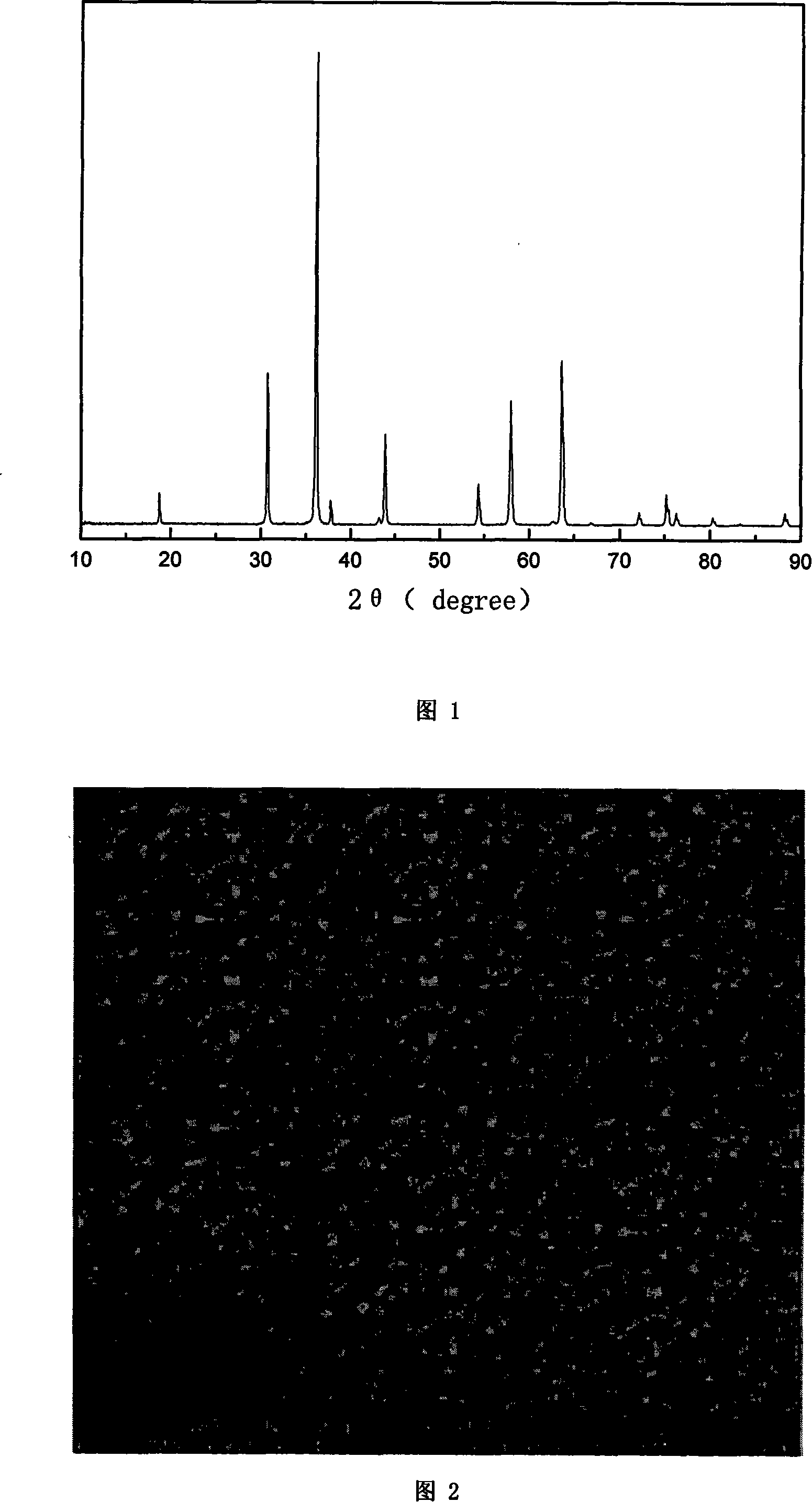

[0021] Put a heat-resistant crucible in the reaction furnace in advance, and raise the temperature of the reaction furnace to 550°C. Accurately weigh 2.1440g (0.01mol) of magnesium acetate, 6.1960g (0.02mol) of gallium nitrate, 3.0415g (0.038mol) of ammonium nitrate, and 2.1622g (0.036mol) of urea. Put the four raw materials into a mortar and grind until a uniform precursor paste is formed, then move the paste into a crucible in the reaction furnace and ignite it, and after burning for 15 seconds, nano-magnesium gallate powder is obtained. According to SEM and XRD analysis, the product is high-purity MgGa with particle size below 45nm 2 o 4 crystals.

Embodiment 2

[0022] Embodiment 2 (with citric acid as organic fuel):

[0023] Put a heat-resistant crucible in the reaction furnace in advance, and raise the temperature of the reaction furnace to 500°C. Accurately weigh 3.2160g (0.015mol) of magnesium acetate, 9.2939g (0.03mol) of gallium nitrate, 7.8039g (0.0975mol) of ammonium nitrate, and 4.7282g (0.0225mol) of citric acid. Put the four raw materials into a mortar and grind until a uniform precursor paste is formed, then move the paste into a crucible in the reaction furnace and ignite it, and after burning for 24 seconds, nano-magnesium gallate powder is obtained. According to SEM and XRD analysis, the product is high-purity MgGa with particle size below 50nm 2 o 4 crystals.

Embodiment 3

[0024] Embodiment 3 (using urea as organic fuel)

[0025] Put a heat-resistant crucible in the reaction furnace in advance, and raise the temperature of the reaction furnace to 400°C. Accurately weigh 2.1440g (0.01mol) of magnesium acetate, 6.1960g (0.02mol) of gallium nitrate, 4.9625g (0.062mol) of ammonium nitrate, and 2.6426g (0.044mol) of urea. Put the four raw materials into a mortar and grind until a uniform precursor paste is formed, then move the paste into a crucible in the reaction furnace and ignite it, and after burning for 20 seconds, nano-magnesium gallate powder is obtained. According to SEM and XRD analysis, the product is high-purity MgGa with particle size below 40nm 2 o 4 crystals.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com