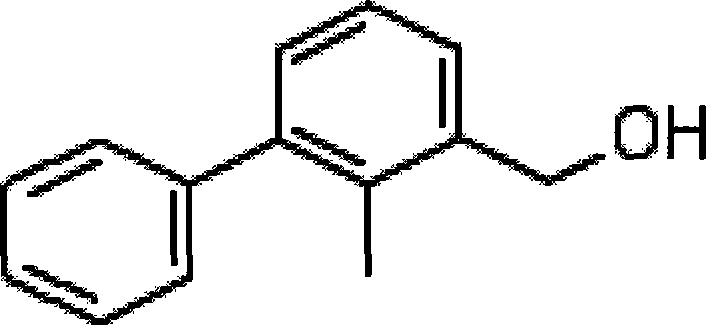

Process for producing 2- methyl group -3- phenylbenzene methanol cleanly

A technology of phenylbenzyl alcohol and clean production, applied in hydrolysis preparation, organic chemistry, etc., can solve problems such as difficult water purification, no application value, difficult separation by biochemical or physical and chemical methods, and achieve the effect of eliminating emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is further illustrated below by way of examples.

[0035] (1) Add 1050Kg of tetrahydrofuran, 120Kg of magnesium powder, and 10Kg of ethyl bromide into the reaction kettle, and stir. After the reaction is triggered, add 2,6-dichlorotoluene dropwise under reflux to a total of 750Kg. After the Grignard reaction is completed, keep the temperature below 60°C for 2 hours , get the first grignard material, and transfer it to the header tank.

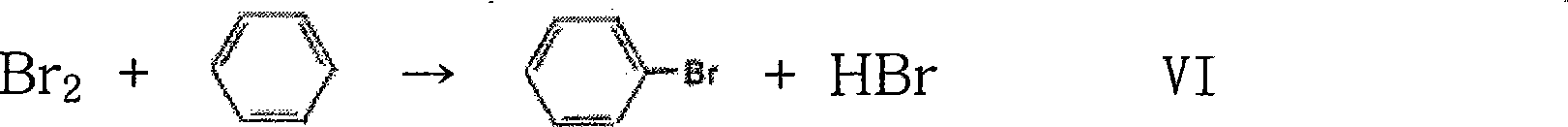

[0036] Add 750Kg of bromobenzene, 2.5kg of catalyst, and 40Kg of tetrahydrofuran into the coupling reaction kettle, stir, add the first Grignard material dropwise under reflux at 110-120°C, and drop it in 3-5 hours to obtain the coupling material, adjust it with hydrobromic acid To pH2-3, hydrolysis reaction, then gradually increase the temperature to 90-110°C, recover the distilled tetrahydrofuran, cool down the feed liquid, add 300Kg water, separate the water phase and the oil phase, separate the oil layer, wash w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com