High-effective clean method for preparing soybean isoflavone aglycone

A technology of isoflavone aglycone and soybean, which is applied in the field of preparation of functional soybean isoflavones, to achieve the effect of accelerating the reaction speed, short production cycle, simple and easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: the preparation of β-glucosidase:

[0032] The preparation of β-glucosidase in the present invention can be Thermotoga maritima (specific operation reference Yu Jiang, Qing Zhou, Kang Wu, Xiangqian Li, and Weilan Shao.A highly efficient method for liquid and solid cultivation of the anaerobic hyperthermophilic eubacterium Thermotogamaritima.FEMS Microbiol Lett, 2006, 259: 254-259) in a medium containing 1.0% glucose, 0.5g% yeast powder, 2.7% NaCl, filled with CO at a temperature of 80°C 2 and N 2 Cells were collected and broken after static culture for 8-10 hours under the condition, and the supernatant was collected by centrifugation, and the enzyme protein was precipitated with 65% saturated ammonium sulfate, and then dialyzed with 0.02M, pH5.5 phosphate buffer solution and freeze-dried to obtain β- Glucosidase.

Embodiment 2

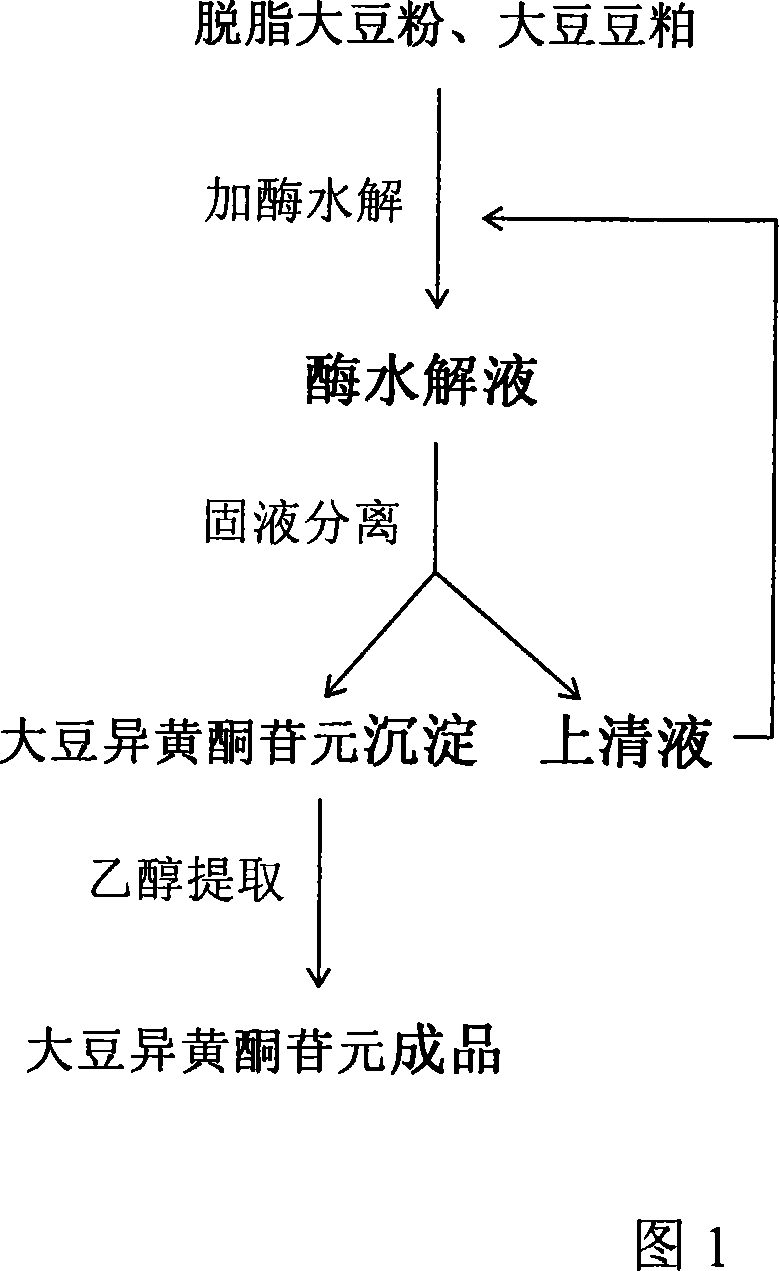

[0034] The process shown in Figure 1, the specific operations are as follows:

[0035] (1) Grinding the mildew-free soybeans into 80-mesh soybean powder after removing impurities, and then extracting and removing fat with n-hexane to obtain defatted soybean powder;

[0036] (2) Dissolve the defatted soybean powder in pH 6.2 100mM sodium phosphate buffer solution at a material-to-water ratio of 1:4, heat to 90°C while stirring, add 800U / g Thermotoga maritima β-glucosidase, keep warm and Stir at low speed for 3 hours;

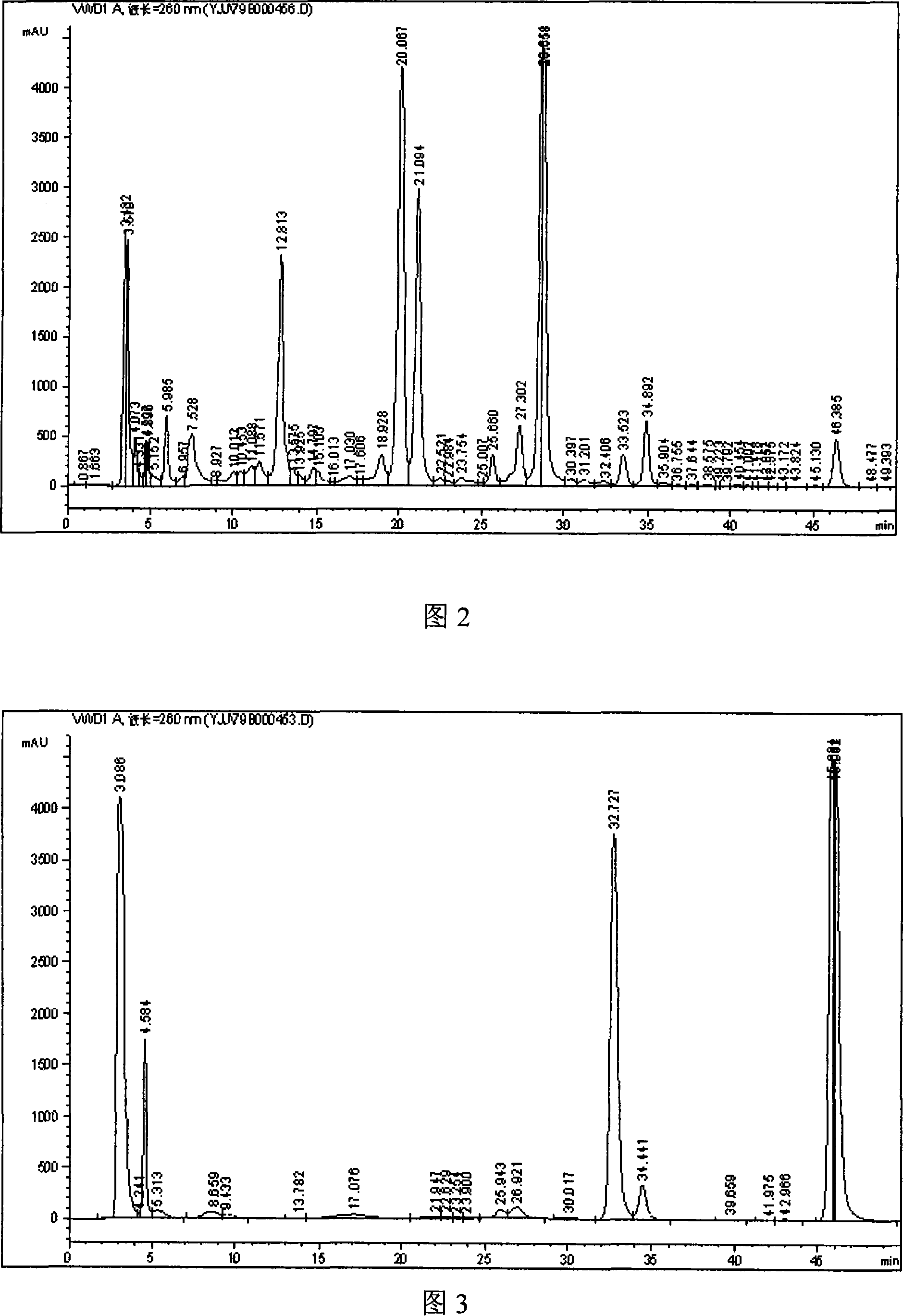

[0037] (3) The obtained enzymolysis solution was separated by centrifugation, and the precipitate was extracted with 10 times the volume of 80% ethanol at 80°C for 2 hours, then suction filtered to remove the residue, and the filtrate was further vacuum freeze-dried, and the obtained product was detected by HPLC. The composition of isoflavones is shown in Figure 3; HPLC analysis conditions: chromatographic column: Agilent HC-C 18 (4.6mm×250mm ID, 5μm); column t...

Embodiment 3

[0038] Embodiment 3: It is basically the same as Embodiment 1, except that the raw material used is soybean meal purchased from a domestic biotechnology company. The feed solution was prepared by dissolving soybean meal in pH 5 citric acid buffer solution with a feed-to-water ratio of 1:3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com