Handling method for refractory waste water

A treatment method and refractory technology, applied in the field of using acoustic-magnetic coupling to strengthen microorganisms to treat refractory wastewater, can solve the problems of clogging reactor aeration system and pipeline, unsuitable for technology promotion and application, and affecting the formation of sludge flocs, etc. Achieve the effects of shortening the start-up time, preventing swelling and improving microbial activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

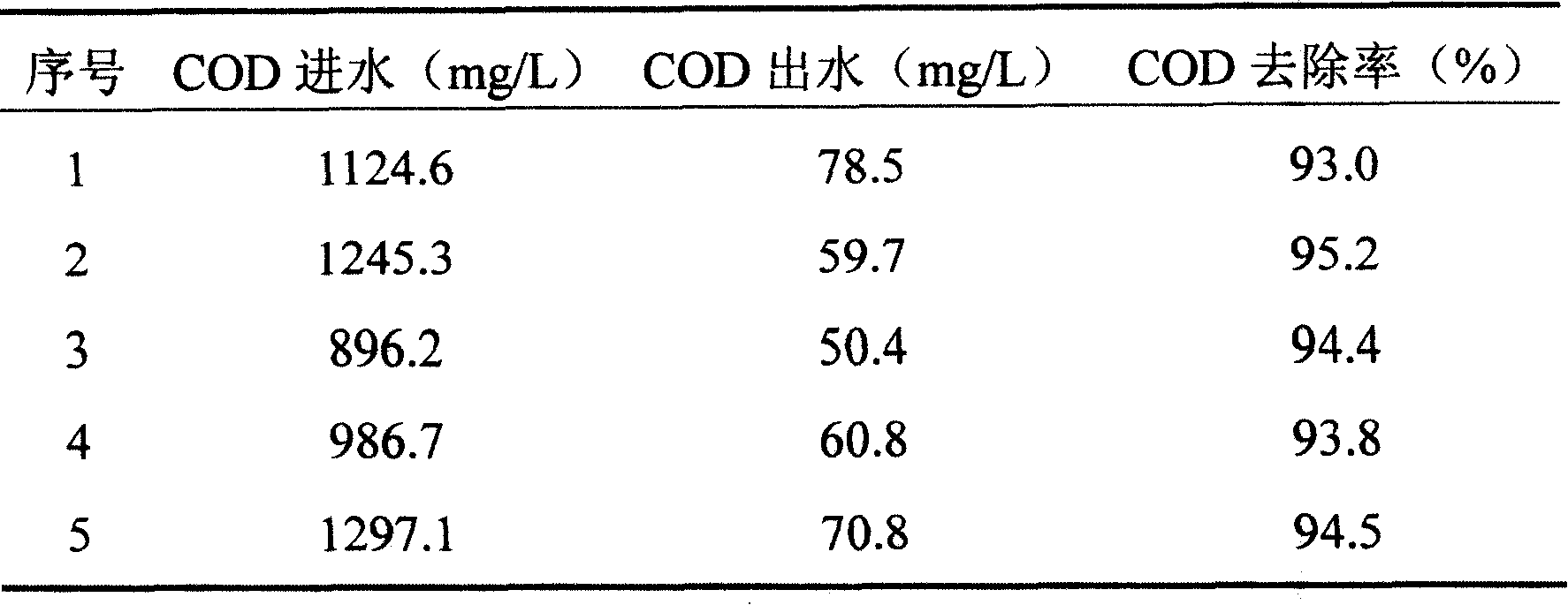

[0022] Example 1: Aerobic biological treatment of refractory substances in oil refinery wastewater

[0023] Refinery wastewater mainly contains pollutants such as alkanes, aromatic hydrocarbons, volatile phenols and ammonia nitrogen, among which long-chain alkanes and diethyl phthalate, benzenesulfonate, 2,4-dichlorotoluene, p-nitrobenzene Aromatics such as formic acid and halogenated aromatics are refractory substances, and whether they are treated thoroughly will directly affect whether the effluent can meet the standard.

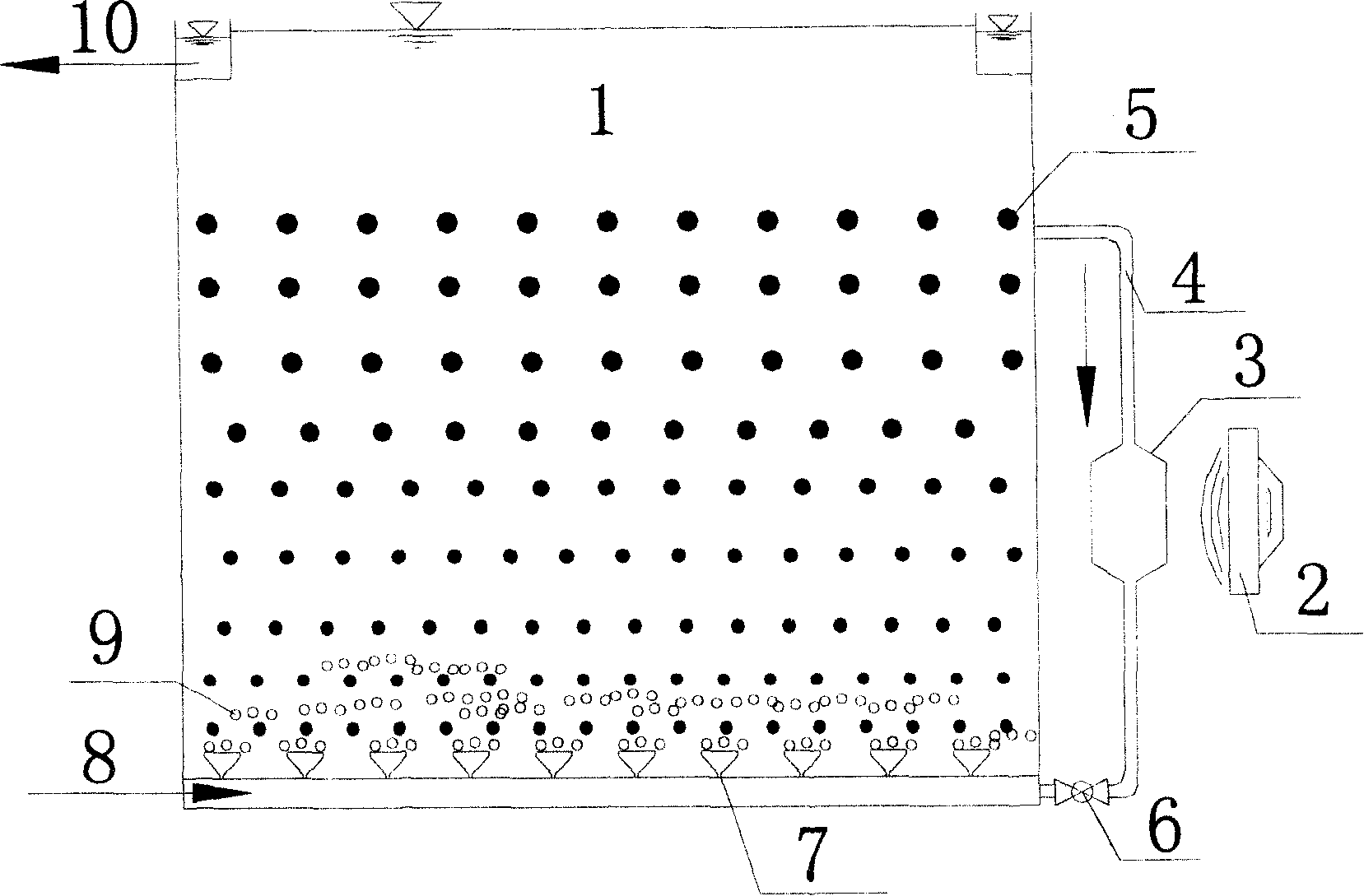

[0024] use figure 1 The shown wastewater biological aerobic treatment reactor, adding 100L COD is 800 ~ 1300mg / L oil refinery wastewater, the reactor adopts the sequence batch operation mode, according to the patent "a microbial agent for oil refinery wastewater treatment, its preparation method and its application "(Patent Publication No.: CN1789406) To prepare the microbial agent, add the liquid microbial agent according to 2% of the effective volume o...

Embodiment 2

[0028] Example 2: Anaerobic treatment of refractory substances in pharmaceutical wastewater

[0029] Pharmaceutical wastewater has the characteristics of high organic matter concentration, high SS concentration, and high sulfate concentration. At the same time, there are difficult biodegradation and toxic substances such as antibacterial, antibacterial, and antibiotics. active. Using acoustic-magnetic coupling physical energy field to strengthen microorganisms for degradation can improve COD removal rate and impact load resistance performance.

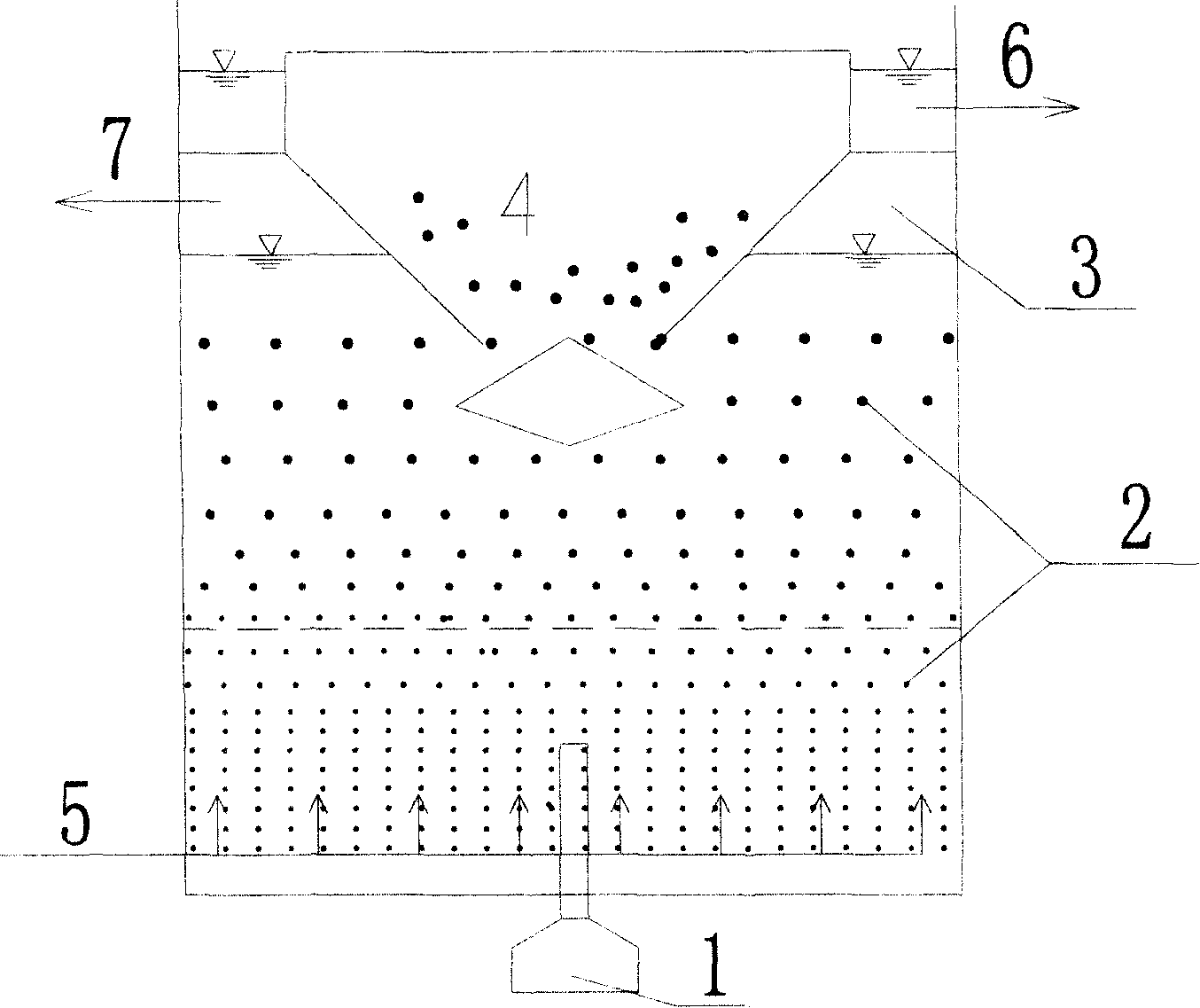

[0030] use figure 2The anaerobic reactor shown is inoculated with anaerobic sludge, and magnetic powder is added at a dosage of 90 mg / L. The magnetic powder is made of oxidized magnets, and the particle size of the magnetic powder is 0.1-15 μm. The magnetic field strength on the surface of the reactor is controlled at 5-15 mT. The device is directly installed at the bottom of the reactor, the ultrasonic frequency is 30KHz, and the u...

Embodiment 3

[0033] Example 3: Aerobic treatment of refractory substances in printing and dyeing wastewater

[0034] The complex organic compounds containing azo bonds and polyaromatic rings in printing and dyeing wastewater, most of the dyes are toxic and refractory organic compounds, with strong chemical stability and three effects. Among them, compounds such as PVA are difficult to degrade.

[0035] use figure 1 The shown wastewater biological aerobic treatment reactor, add 100L COD to 2100 ~ 2500mg / L printing and dyeing wastewater, the reactor adopts the sequential batch operation mode, inoculate the sludge, and at the same time add microbial agents according to 2% of the effective volume of the reactor ( Contains PVA degrading bacteria, decolorizing bacteria, aromatics degrading bacteria and other high-efficiency microorganisms), adopts two-stage aerobic treatment process, the first stage adopts granular sludge treatment, the hydraulic retention time is 16h, and the second stage adop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com