Heating unit of infrared electric heating plate and producing method

A heating element and electric heater technology, applied in the direction of electric heating devices, ohmic resistance heating, electrical components, etc., can solve the problems of low efficiency of infrared radiation energy, energy loss, etc., to increase the radiation area, high energy conversion efficiency, and improve heating efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

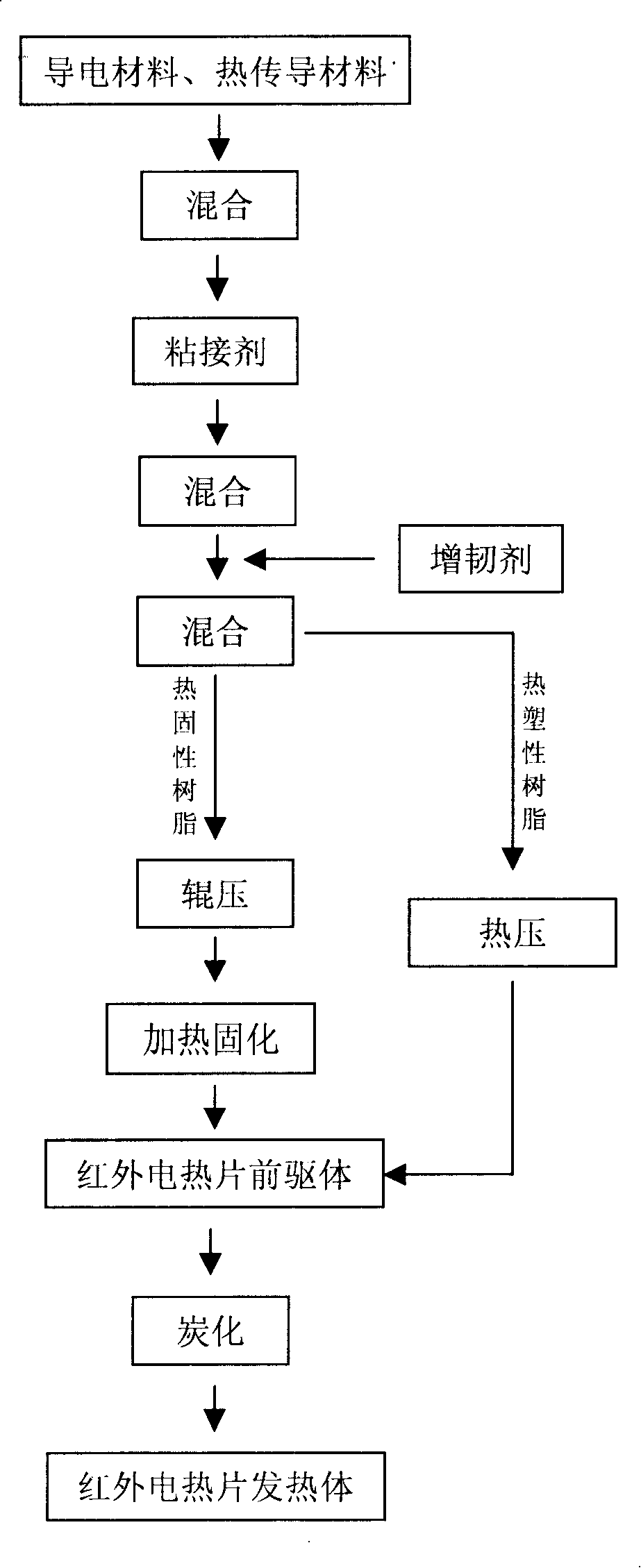

[0023] The preparation process of the infrared heating element heating element of the present invention is as follows:

[0024] 1. Preparation of infrared heater precursor

[0025] When thermosetting resin is used as adhesive, heat curing method is used: first, make a uniform mixture of conductive material and thermal conductive material in a mixer, then add it to the adhesive being stirred, after stirring evenly, add toughening agent , continue stirring to form a homogeneous mixture. The above mixture is made into a thin sheet on a twin-roll machine, and then solidified on a flat vulcanizer at 65-150° C. for 0.5-5 hours, and cooled naturally to room temperature to obtain an infrared heater precursor.

[0026] When using thermoplastic resin, use hot pressing method: first make a uniform mixture of conductive material and heat conductive material in a mixer, then add it to the adhesive, and after stirring evenly, add a toughening agent and continue stirring to make a uniform m...

Embodiment 1

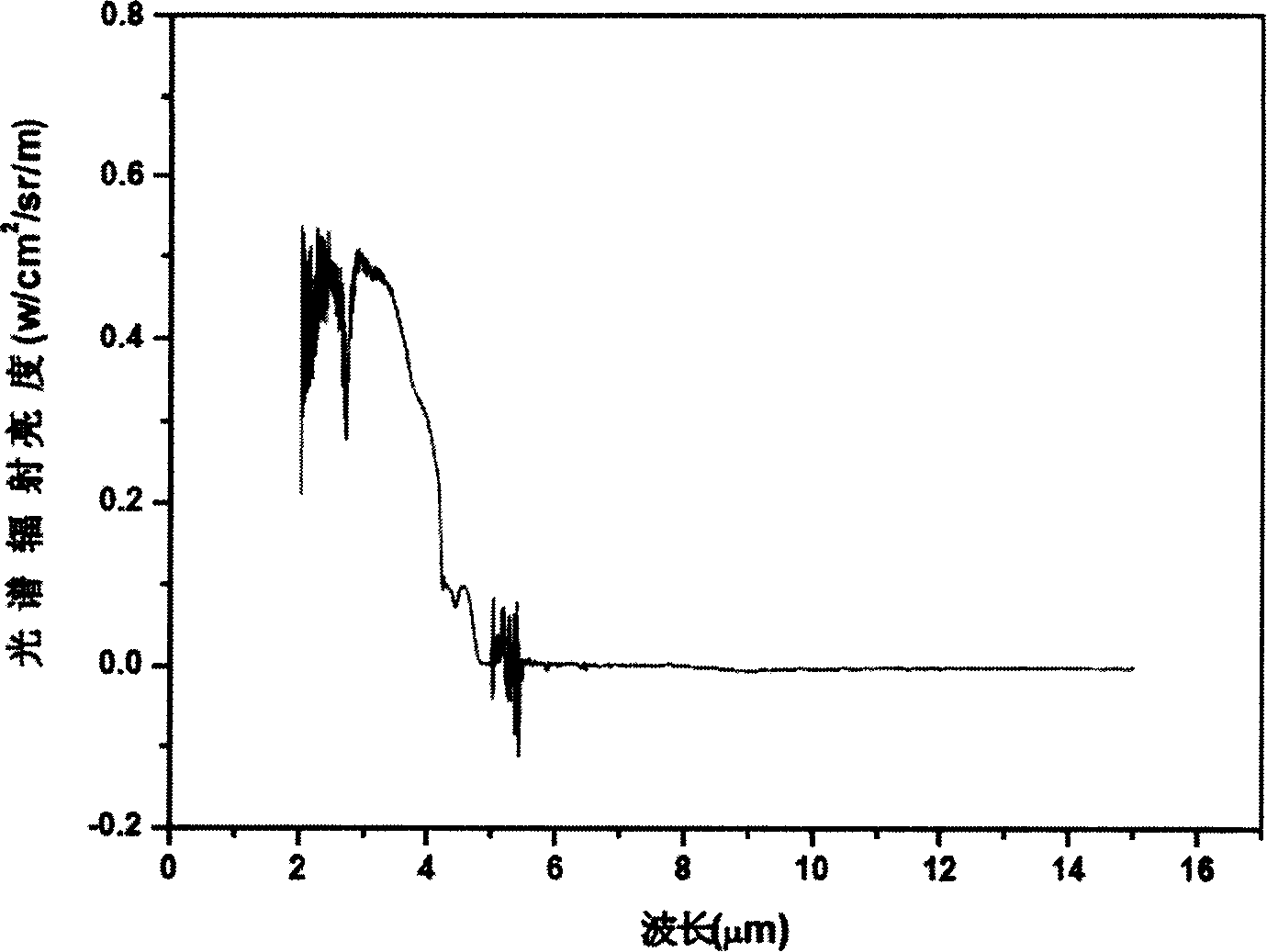

[0029] Embodiment 1 flake graphite (particle size is 45 μ m), silicon carbide (particle size is 15 μ m), epoxy resin, ethanol is 2.5: 88: 7.5: 2 mix homogeneously according to weight ratio, after making 1mm flake on the two-roller machine, on flat plate Heat and solidify at 65°C on a vulcanizer for 3 hours, and cool naturally to room temperature to obtain the precursor of the infrared heater. The infrared heater precursor was carbonized at 900° C. for 6 hours under a nitrogen atmosphere to obtain an infrared heater heater. The maximum spectral radiance of the surface measured by infrared emission spectroscopy is 0.49w / cm 2 / sr / m, the corresponding wavelength is 2.41μm, and the maximum radiation temperature of the heating element of the infrared heater is 929.3℃ (see figure 2 ).

Embodiment 2

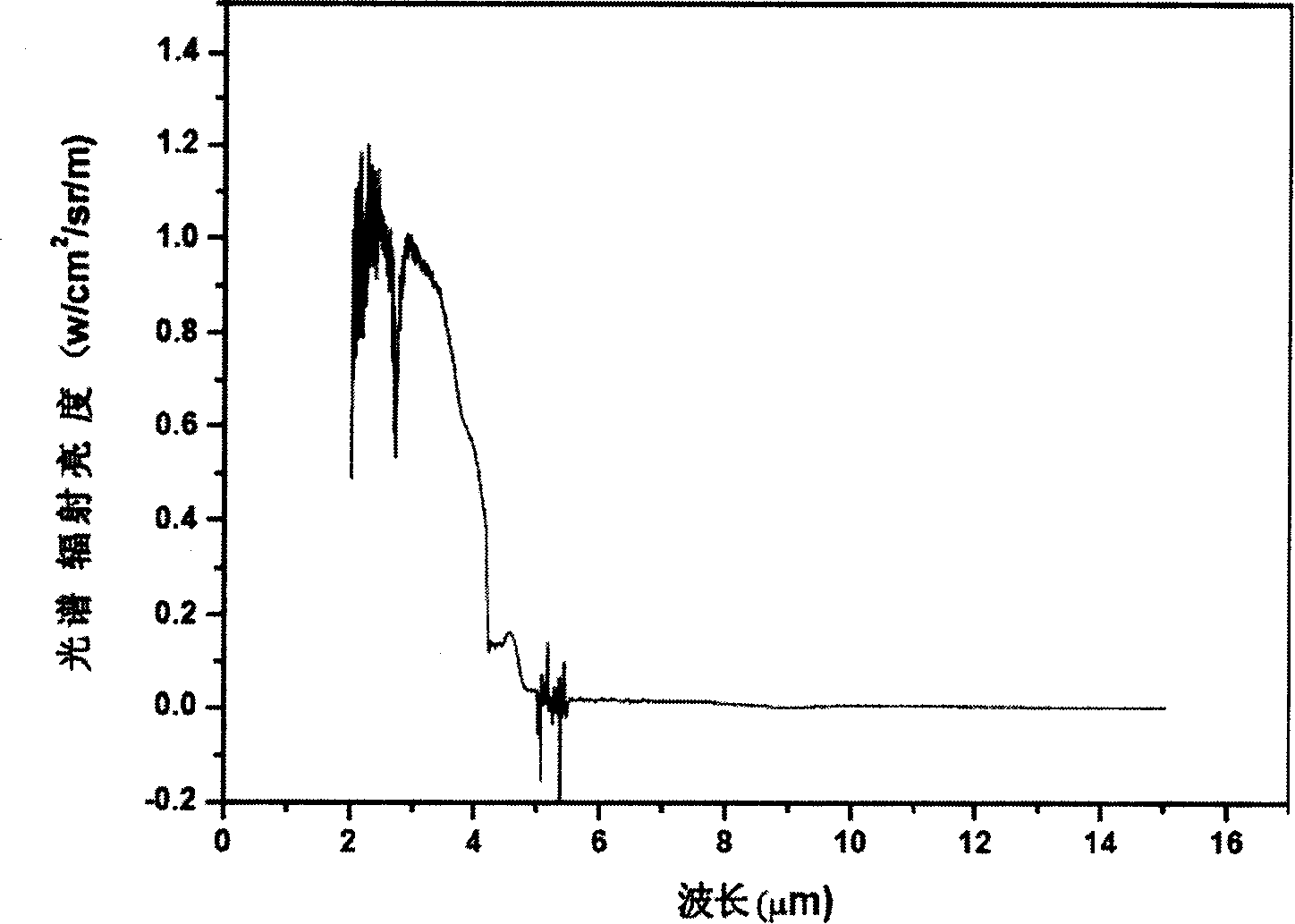

[0030] Example 2 Conductive carbon black (particle size is 20mm), silicon dioxide (particle size is 25 μm), ABS resin and glycerol are mixed uniformly by weight 3: 14: 2: 1, then on a flat vulcanizer, heat under 300 ℃ and 15MPa Press for 15 minutes to make a hot-pressed sheet with a thickness of 1 mm, and cool it down to room temperature naturally to obtain an infrared heater precursor. The infrared heater precursor was carbonized at 1000° C. for 9 hours under an argon atmosphere to obtain an infrared heater heater. The maximum spectral radiance of the surface measured by infrared emission spectroscopy is 1.05w / cm 2 / sr / m, the corresponding wavelength is 2.37μm, and the maximum radiation temperature of the heating element of the infrared heater is 949.6°C (see image 3 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com