Method for high concentration mass-synthesis of silver nano-wire

A silver nanowire and high-concentration technology, applied in the field of nanomaterials, can solve the problems of difficulty in large-scale industrial application, easy aggregation of nanomaterials, unfavorable single operation or measurement, etc., to achieve rich functions, strong controllability, superiority The effect of optical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

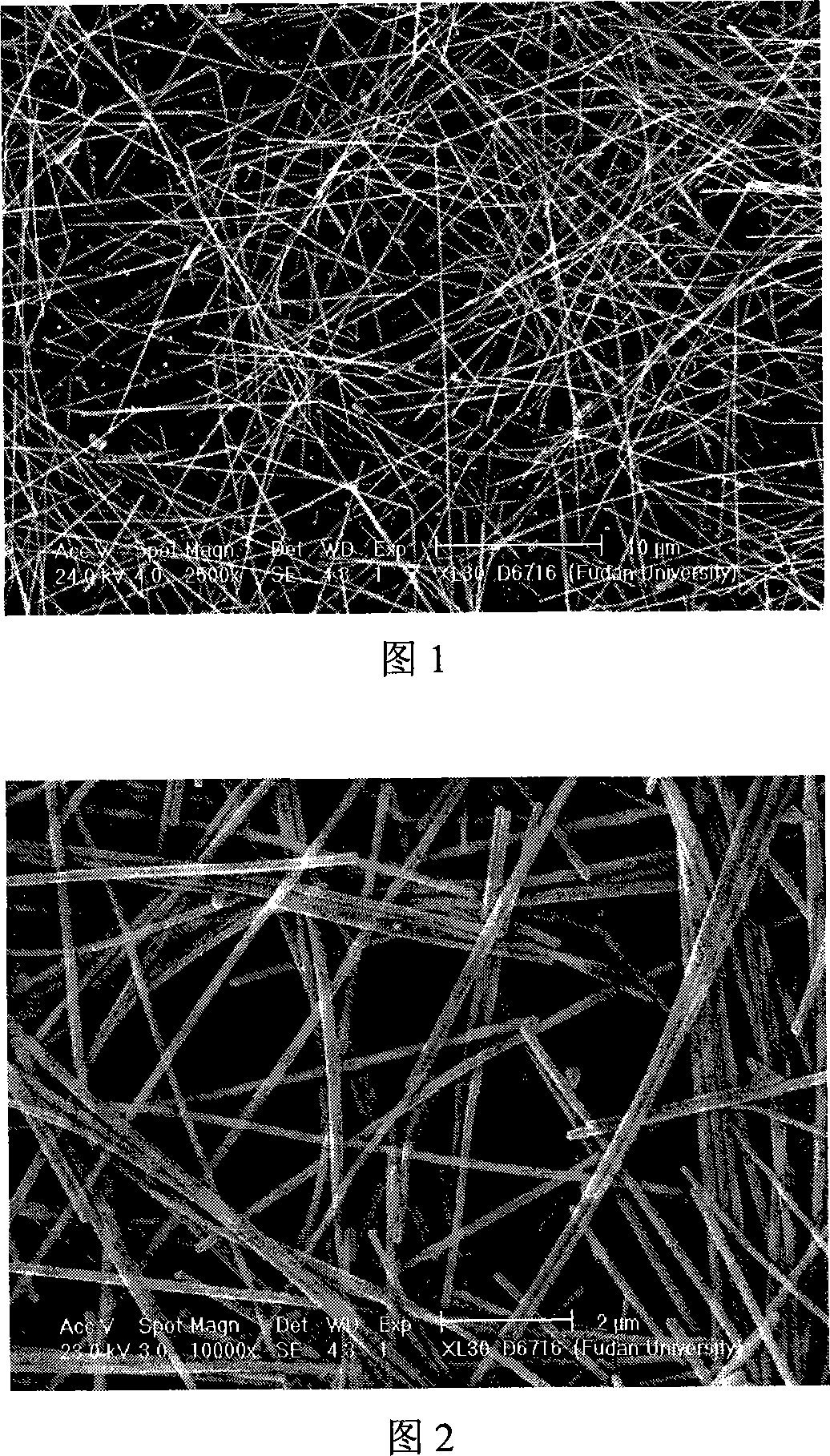

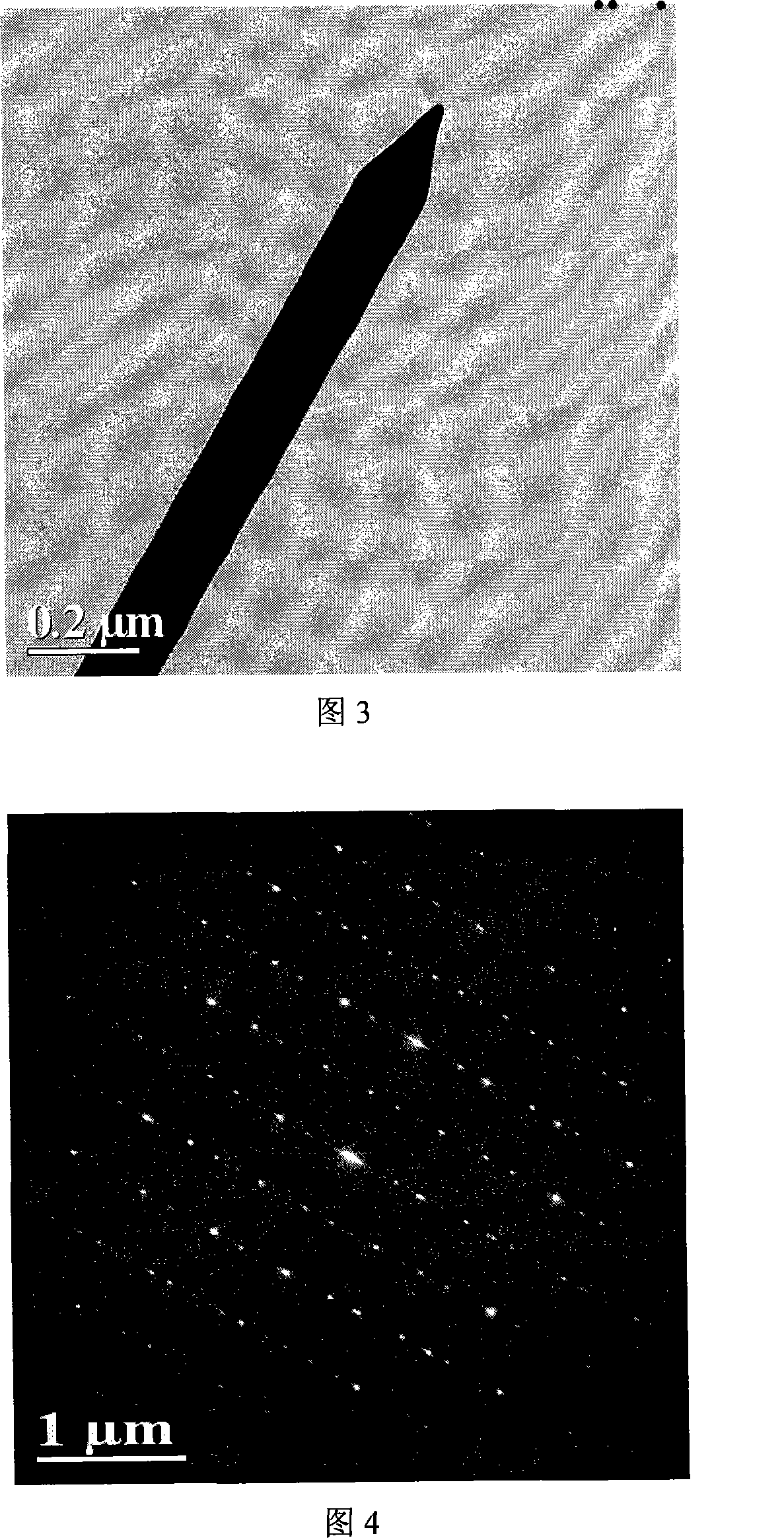

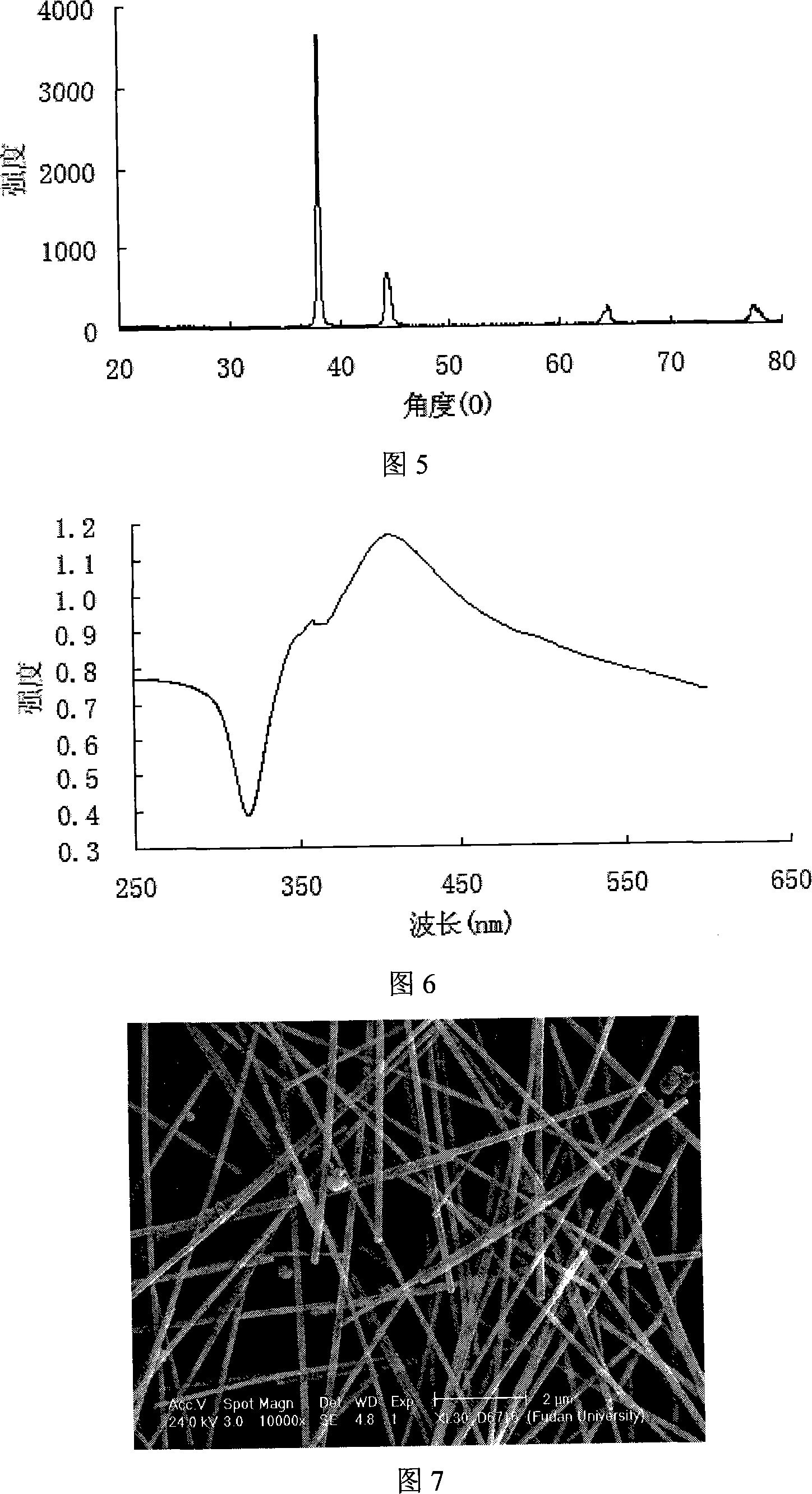

[0032] Mix silver nitrate, ethylene glycol, and polyvinylpyrrolidone and dissolve them with stirring or ultrasonic waves; pour the mixed solution and stainless steel pieces into a flask, and use a reflux device to react in an oil bath at 100-200°C. The reaction time is 30-200°C. For 300 minutes, a nitrogen gas stream with a gas velocity of 100 cubic centimeters per minute was introduced during the process; after the reacted gray liquid was separated from the stainless steel sheet, the liquid was separated by centrifugation, washed with ethanol three times, and dried at 40-50°C for 8-12 hour to get product

[0033] Dissolve 0.54g of silver nitrate, 0.54g of polyvinylpyrrolidone and 12g of ethylene glycol under ultrasonic waves, put them into a 100ml reaction flask together with 1.0g of stainless steel sheet (grade 304), condense the condensed water in an oil bath at 180°C, and react for 120 minutes , the liquid product was separated from the stainless steel sheet, centrifuged a...

Embodiment 2

[0035] Carry out experiment with the method identical with embodiment 1, but reduce silver nitrate amount to be 0.17g and polyvinylpyrrolidone to be 0.17g., available product B.

Embodiment 3

[0037] Carry out experiment with the method identical with embodiment 1, but increase silver nitrate amount to be 0.68g and polyvinylpyrrolidone to be 0.68g., available product C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com