Method for preparing S-adenomethionine

A technology of adenosylmethionine and methionine, which is applied in the field of preparation of S-adenosylmethionine, can solve the problems of increasing the difficulty of separation process, long fermentation period, cumbersome process and the like, and achieves simplified operation, easy regeneration and good enzyme stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

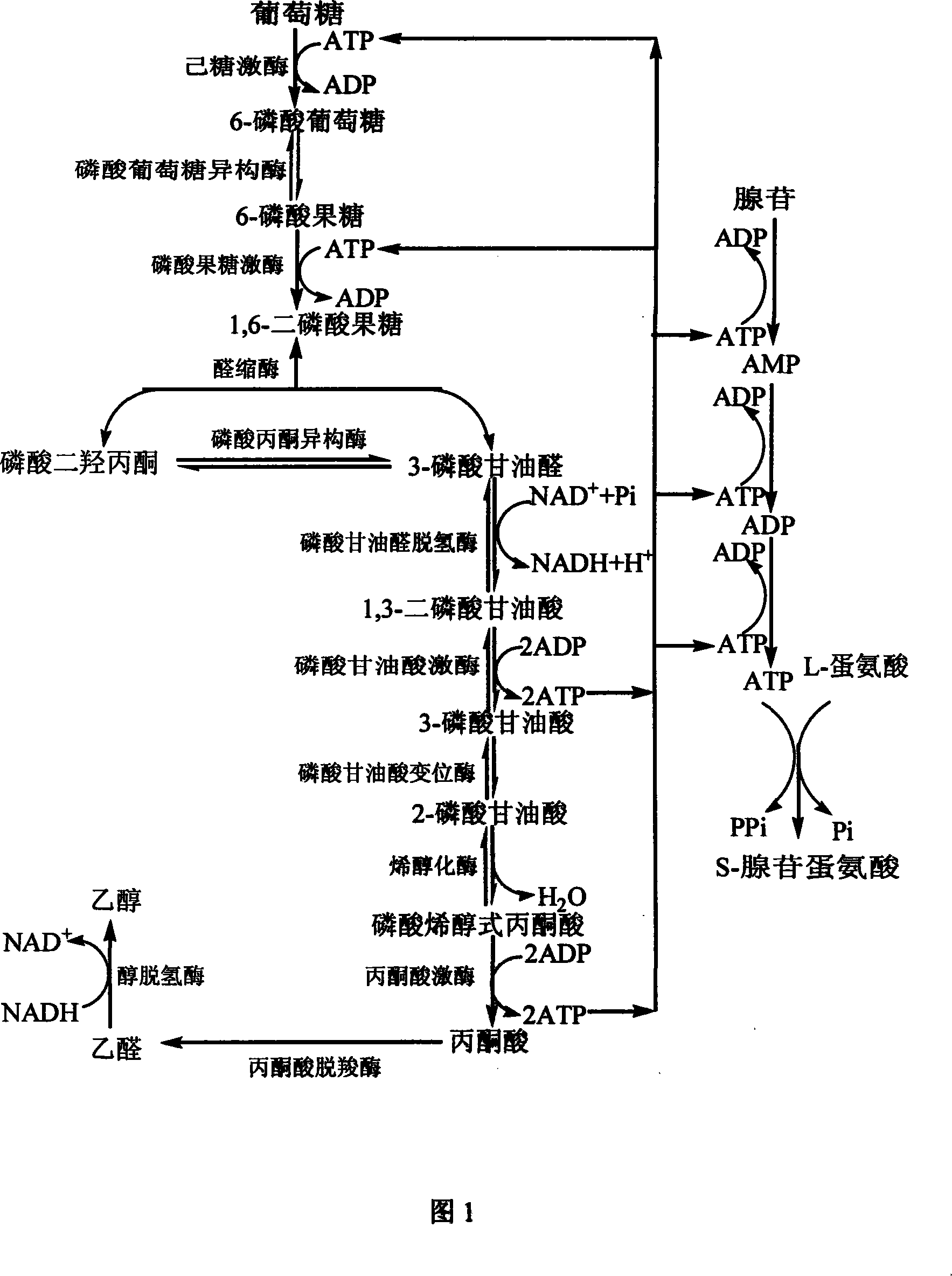

Method used

Image

Examples

Embodiment 1

[0029] Yeast medium: glucose 40g / L, urea 2.0g / L, potassium dihydrogen phosphate 1.5g / L, magnesium sulfate heptahydrate 0.5g / L, zinc sulfate heptahydrate 4.0×10 -3 g / L, ferrous sulfate heptahydrate 3.0×10 -3 g / L, manganese chloride tetrahydrate 0.3×10 -3 g / L, anhydrous calcium chloride 1.0×10 -3 g / L, biotin 0.05×10 -3 g / L.

[0030] The inoculum amount of yeast was 10%, cultured on a shaker at 120 rpm at 30°C for 24 hours, and centrifuged at 4000 rpm for 20 minutes. Take the yeast paste and store it at -7°C for later use.

Embodiment 2

[0031] Example 2: Using glucose as an energy donor, using AMP to synthesize SAM.

[0032] Take a 500ml shake flask, prepare 49mM AMP, 0.14M glucose, 100g Saccharomyces cerevisiae mud, 0.22M potassium dihydrogen phosphate, 157.5mM MgCl 2 , 16.5mM MgSO 4 , 5mM NH 4 Cl, 40.2mM L-Met, 4.5mL toluene, 35mM mannitol, 10mM xylitol, and 300mL reaction liquid, adjust the pH to 6.8 with sodium hydroxide, and stir at 33°C for 4 hours at a low speed. , precipitated with 40% trichloroacetic acid, quantitatively analyzed SAM by HPLC, and contained SAM 4.5g / L in the conversion solution.

Embodiment 3

[0033] Example 3: Using glucose as an energy donor to synthesize SAM using AR.

[0034] Take a 500ml shake flask, prepare 45mM adenosine (AR), 0.2M glucose, 120g air-dried Candida parapsilosis, 0.17M potassium dihydrogen phosphate, 0.044M dipotassium hydrogen phosphate, 210mM MgCl 2 , 3.7mM NH 4 Cl, 40mM L-Met, 30mM glycerol, 54mM mannitol and 300ml of reaction liquid, adjusted pH to 7.0 with potassium hydroxide, stirred at 37°C for 8h at low speed, after the reaction, precipitated with 40% trichloroacetic acid , carry out quantitative analysis to SAM by HPLC, contain SAM 6.5g / L in the conversion liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com