Method and device for producing carbon nano-tube or nitrogen doping carbon nano-tube with liquid phase forerunner article

A technology of carbon nanotubes and nitrogen-doped carbon, which is applied in the direction of nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems of inconstant material quantity, inability to achieve flow sampling, unfavorable and other problems, and achieve easy control of reaction conditions, Expanded range of options, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

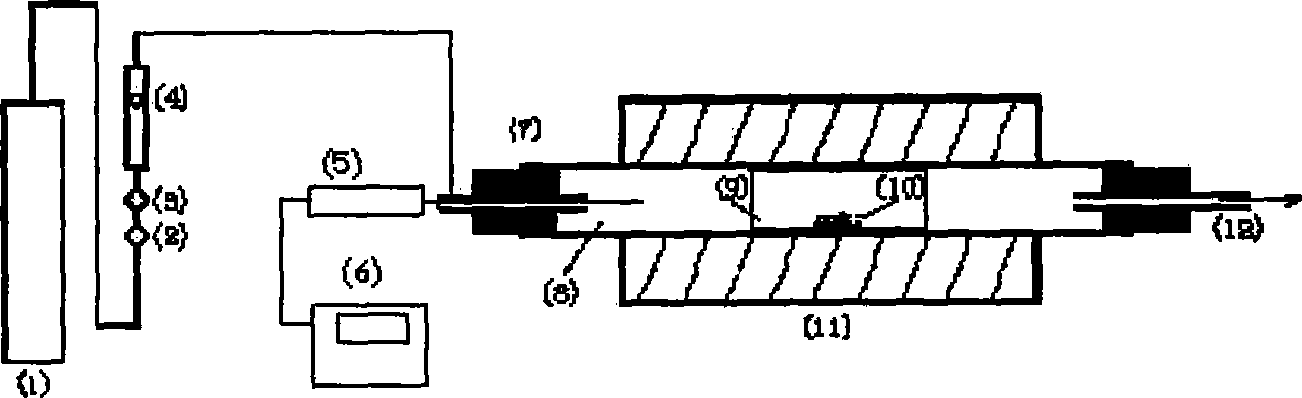

Method used

Image

Examples

Embodiment 1

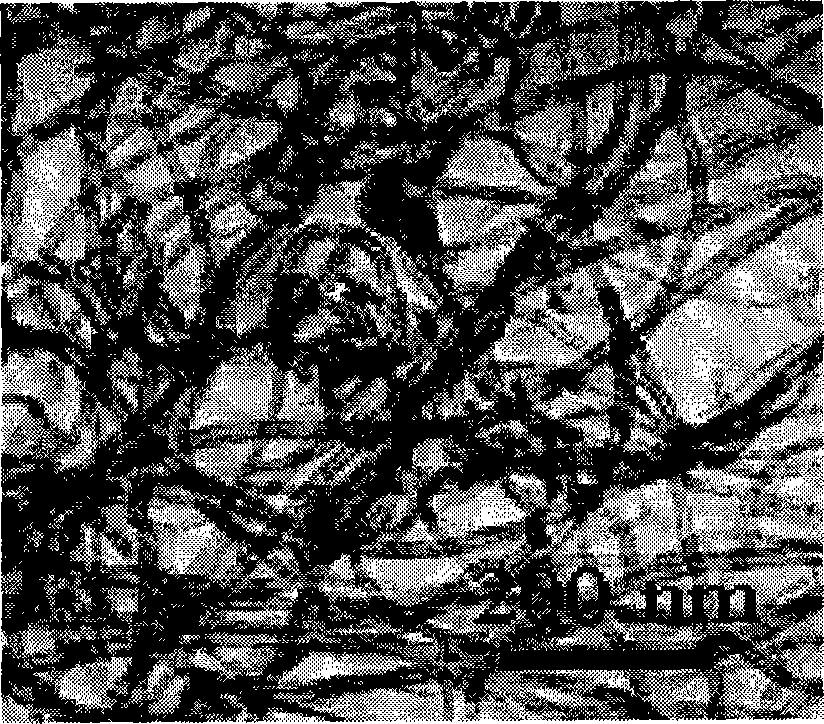

[0041] Example 1 Using benzene as a precursor, 1.0mmol / g Fe-2.0mmol / g Co / γ-Al 2 o 3 As a catalyst, carbon nanotubes are prepared.

[0042] Weigh about 0.4g of catalyst, spread it in the quartz reaction tube, then place the quartz reaction tube in the central temperature zone of the tube furnace, and raise the temperature at a rate of 10°C per minute under an argon or nitrogen atmosphere with a flow rate of 100 sccm to 650°C, and then turn on the syringe pump to inject the benzene precursor into the furnace tube. The distribution coefficient of the syringe pump is 0.75ml / 3hour. g, the utilization of carbon atoms in the benzene precursor is greater than 65%. Transmission electron microscopy (TEM) characterization as figure 2 As shown, the diameter of the nanotube is about 20-30nm, and the length can reach the micron level.

Embodiment 2

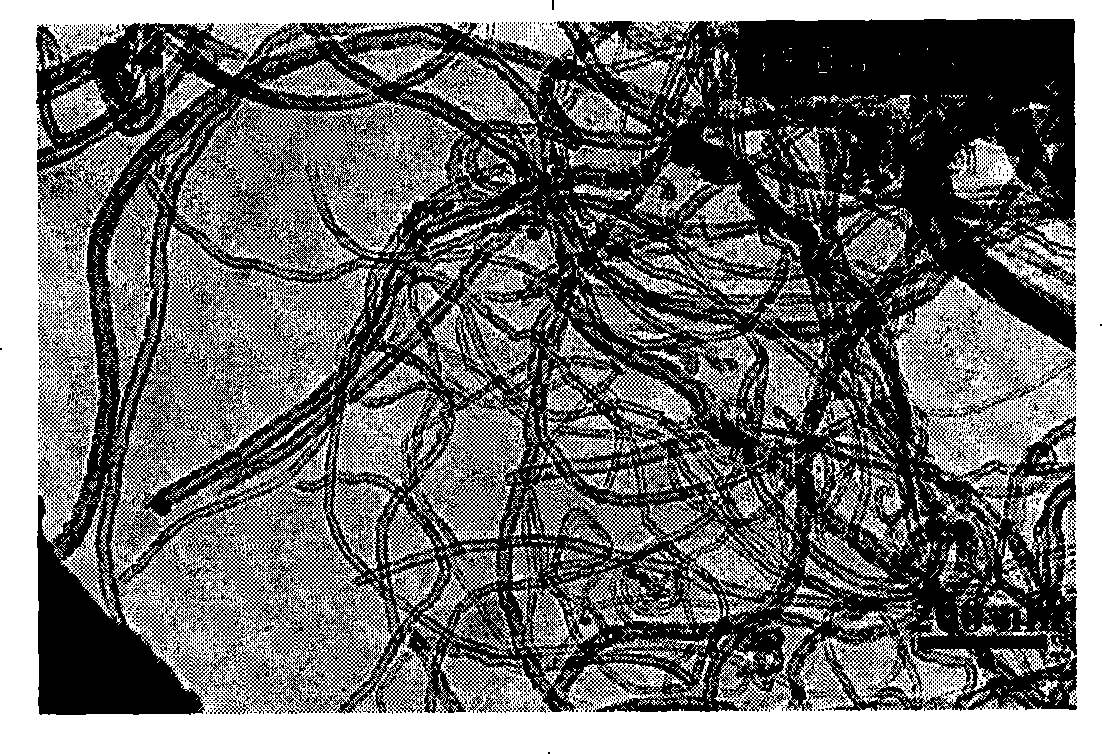

[0043] Example 2 Using pyridine as a precursor, 1.0mmol / g Fe-2.0mmol / g Co / γ-Al 2 o 3 As a catalyst, nitrogen-doped carbon nanotubes were prepared.

[0044] Weigh about 0.4g of catalyst, spread it in the quartz reaction tube, then place the quartz reaction tube in the central temperature zone of the tube furnace, and raise the temperature to 650°C at a rate of 10°C per minute under argon or nitrogen atmosphere (100sccm). ℃, and then turn on the syringe pump (0.75ml / 3hour) to inject the pyridine precursor into the furnace tube. After the reaction, the furnace tube is protected by argon or nitrogen (100 sccm) and lowered to room temperature, and about 0.4 g of the carbon nanotube pyridine precursor is collected. The utilization rate of carbon atoms is greater than 70%. Transmission electron microscopy (TEM) characterization as image 3 As shown, the diameter of the nanotube is about 20-30 nm, and the length can reach the order of microns.

Embodiment 3

[0045] Example 3 Using benzylamine as a precursor, 1.0mmol / g Fe-2.0mmol / g Co / γ-Al 2 o 3 As a catalyst, nitrogen-doped carbon nanotubes were prepared.

[0046] Weigh about 0.4g of catalyst, spread it in the quartz reaction tube, then place the quartz reaction tube in the central temperature zone of the tube furnace, and raise the temperature to 650°C at a rate of 10°C per minute under argon or nitrogen atmosphere (100sccm). ℃, and then turn on the syringe pump (0.75ml / 3hour) to inject the benzylamine precursor into the furnace tube. After the reaction, the furnace tube is lowered to room temperature under the protection of argon or nitrogen (100sccm), and collect about 0.45g of benzylamine for carbon nanotubes The utilization rate of carbon atoms in the precursor is greater than 70%. Transmission electron microscopy (TEM) and photoelectron spectroscopy (XPS) characterizations are shown in Figure 4a) and Figure 4b), and the TEM images show that the diameter of the generated ni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com