Solid base catalyst and applications of biological diesel oil synthesizing

A solid base catalyst, biodiesel technology, applied in physical/chemical process catalysts, biofuels, biological raw materials, etc., can solve the problems of waste of raw materials, time-consuming and energy consumption, and achieve high utilization rate of raw materials, no environmental pollution, and production. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Preparation of the 1st step solid base catalyst

[0017] Put 6g of magnesium acetate and 10g of potassium hydroxide in a mortar, grind at room temperature for about 1 hour, and then roast in a muffle furnace at 800°C for 5 hours to obtain the product.

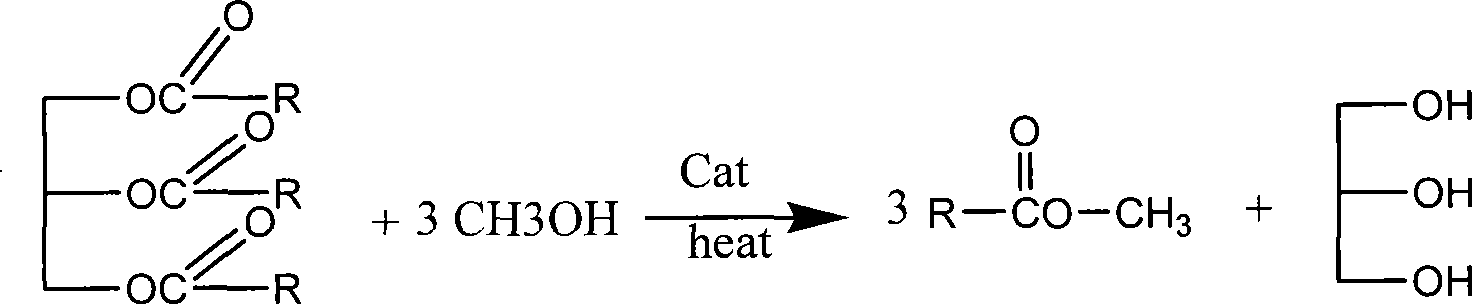

[0018] Step 2 transesterification reaction

[0019] Add 5g of rapeseed oil, 1.5g of methanol, and 0.1g of the above-mentioned solid base catalyst into a 100mL three-necked flask equipped with electromagnetic stirring, a thermometer, and a reflux condenser, heat under reflux and stir for 2 hours, and heat to 90°C.

[0020] Step 3 Separation of catalyst and purification of product

[0021] Filter the material in the three-necked bottle, the filtered catalyst can be directly used for the next reaction, the filtrate is separated to separate the lower glycerin, and the upper layer mixture is added with a mass fraction of 6% NaHCO 3 Solution 70ml washes to neutrality, to remove unreacted free fatty acid, separates the upper ...

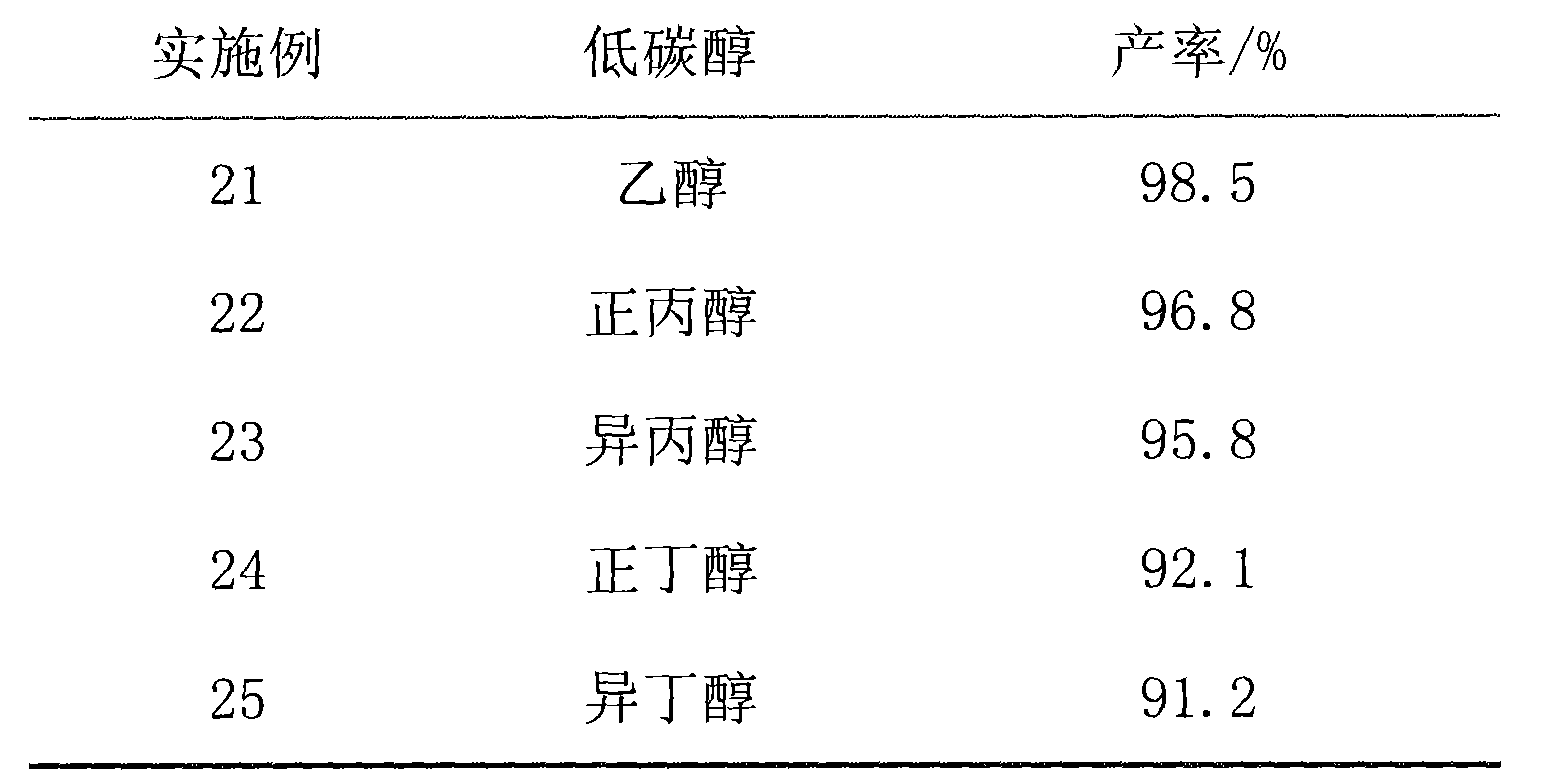

Embodiment 2-6

[0023] Except following difference, all the other are identical with embodiment 1, in the process of preparing catalyst, magnesium acetate is by the consumption of table 1.

[0024] Table 1

[0025]

Embodiment 7-11

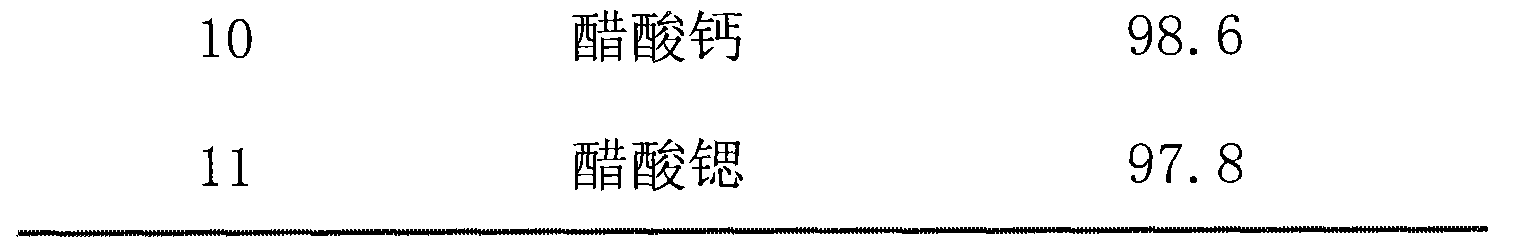

[0027] Except the following differences, all the other are the same as Example 1, adopting the acetates shown in Table 2 respectively.

[0028] Table 2

[0029]

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com