Isosorbide dinitrate oral administration impulse pellet preparations

A technology of pulsed pellets and isosorbide, which is used in medical preparations with non-active ingredients, cardiovascular system diseases, non-active ingredients of oil/fat/wax, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

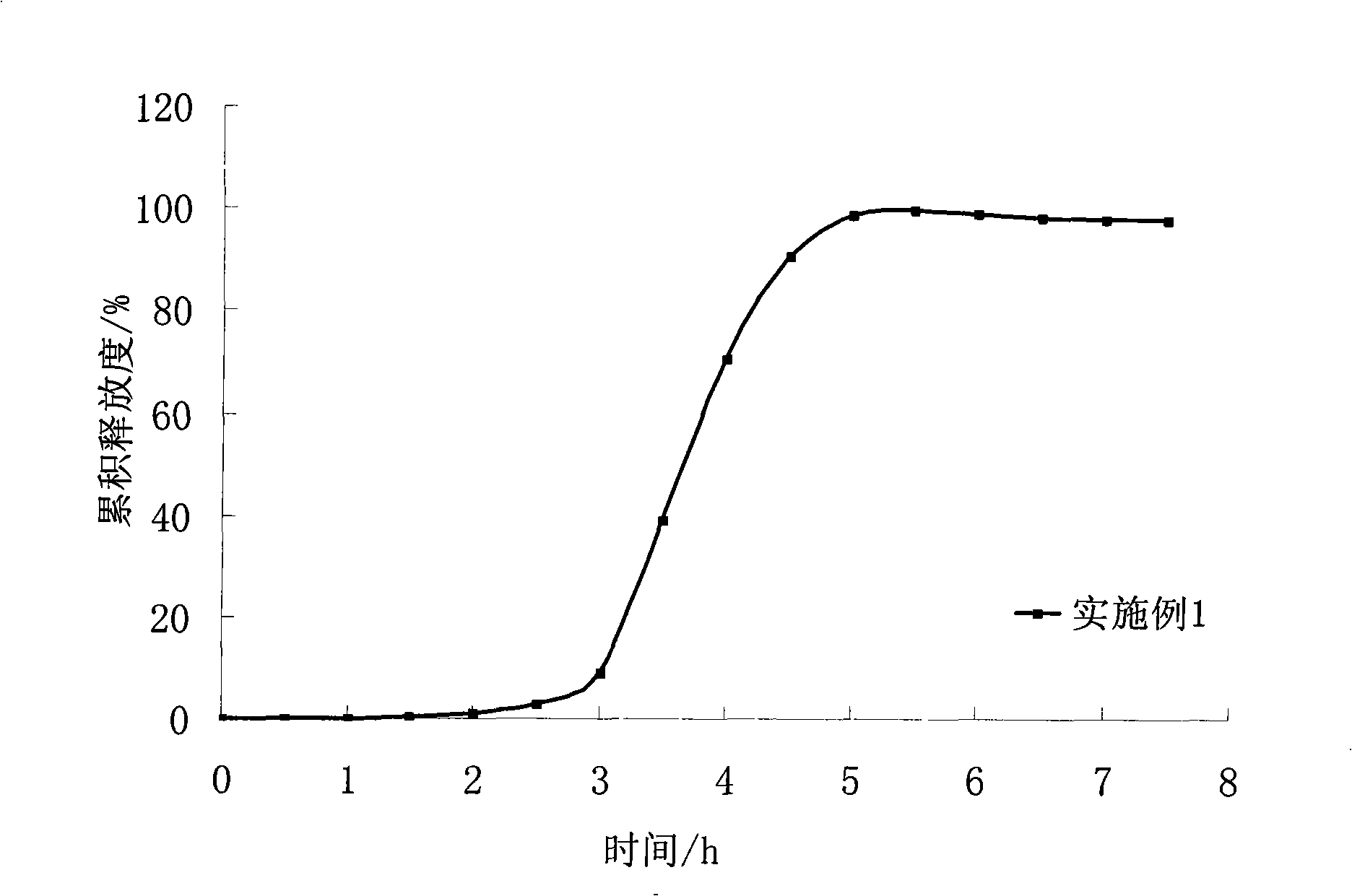

Embodiment 1

[0029] Drug-containing immediate-release pill core prescription:

[0030] Starch sucrose blank core 400g

[0031] Isosorbide Dinitrate 100g

[0032] 95% ethanol 1kg

[0033] Preparation process: Dissolve isosorbide dinitrate in 95% ethanol, apply fluidized bed coating, temperature 32±1°C, flow rate 8mL / min, wrap isosorbide dinitrate on the blank core to obtain Drug immediate release pill core. The average cumulative dissolution rate was 90% in 45 minutes.

[0034] Alkaline Layer Recipe: Sodium Bicarbonate 10% (w / v), add water to 100%

[0035] Preparation process: Dissolve sodium bicarbonate in water, apply fluidized bed coating, temperature 50±1°C, flow rate 3mL / min, wrap sodium bicarbonate on drug-containing immediate-release pellet core, coating weight gain 20%, A pellet core containing an alkaline layer is prepared.

[0036] Hysteresis layer prescription w / v(%)

[0037] Polyacrylic resin III (Eudragit S100) 6.5

[0039] Add 95% ethan...

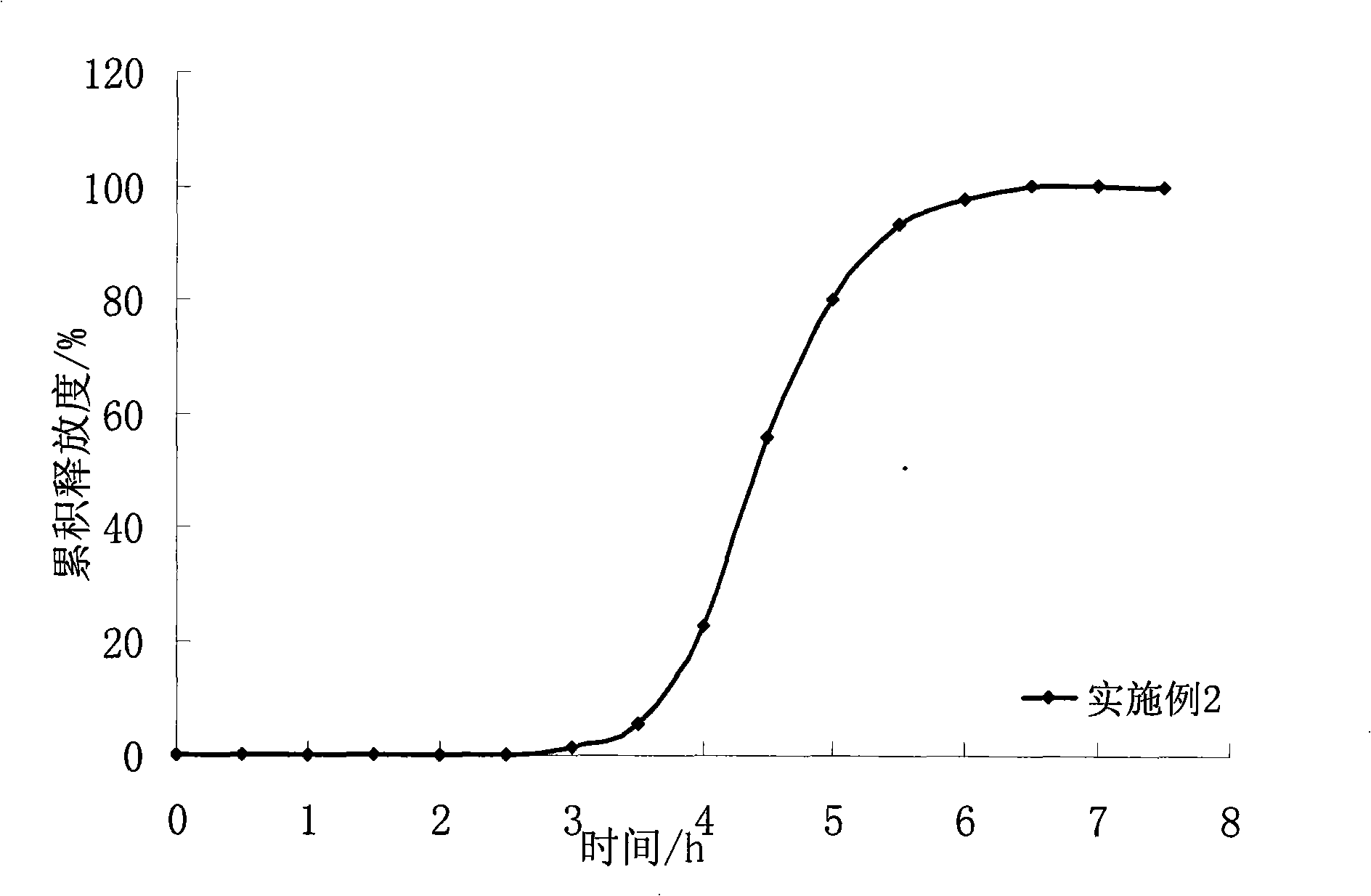

Embodiment 2

[0042] Drug-containing immediate-release pill core prescription:

[0043] Starch sucrose blank core 600g

[0044] Isosorbide Mononitrate 100g

[0045] 95% ethanol 1kg

[0046] The coating process is the same as in Example 1. Get the drug-containing immediate-release pellet core. The average cumulative dissolution rate was 90% in 45 minutes.

[0047] Basic layer: Potassium dihydrogen phosphate 10% (w / v), add water to 100%, the coating process is the same as in Example 1. The weight of the coating increased by 12%, and the ball core containing the basic layer was obtained.

[0048] Hysteresis layer prescription w / v(%)

[0049] Polyacrylic resin III (Eudragit S100) 6

[0050] Micronized silica gel 1.4

[0051] Add 95% ethanol to 100%,

[0052] The coating process is the same as in Example 1. Coating weight gain of 120%. The obtained pulse pellet release curve is shown in the appendix figure 2 : Lags for about 3.5 hours, then releases completely within 2 hours.

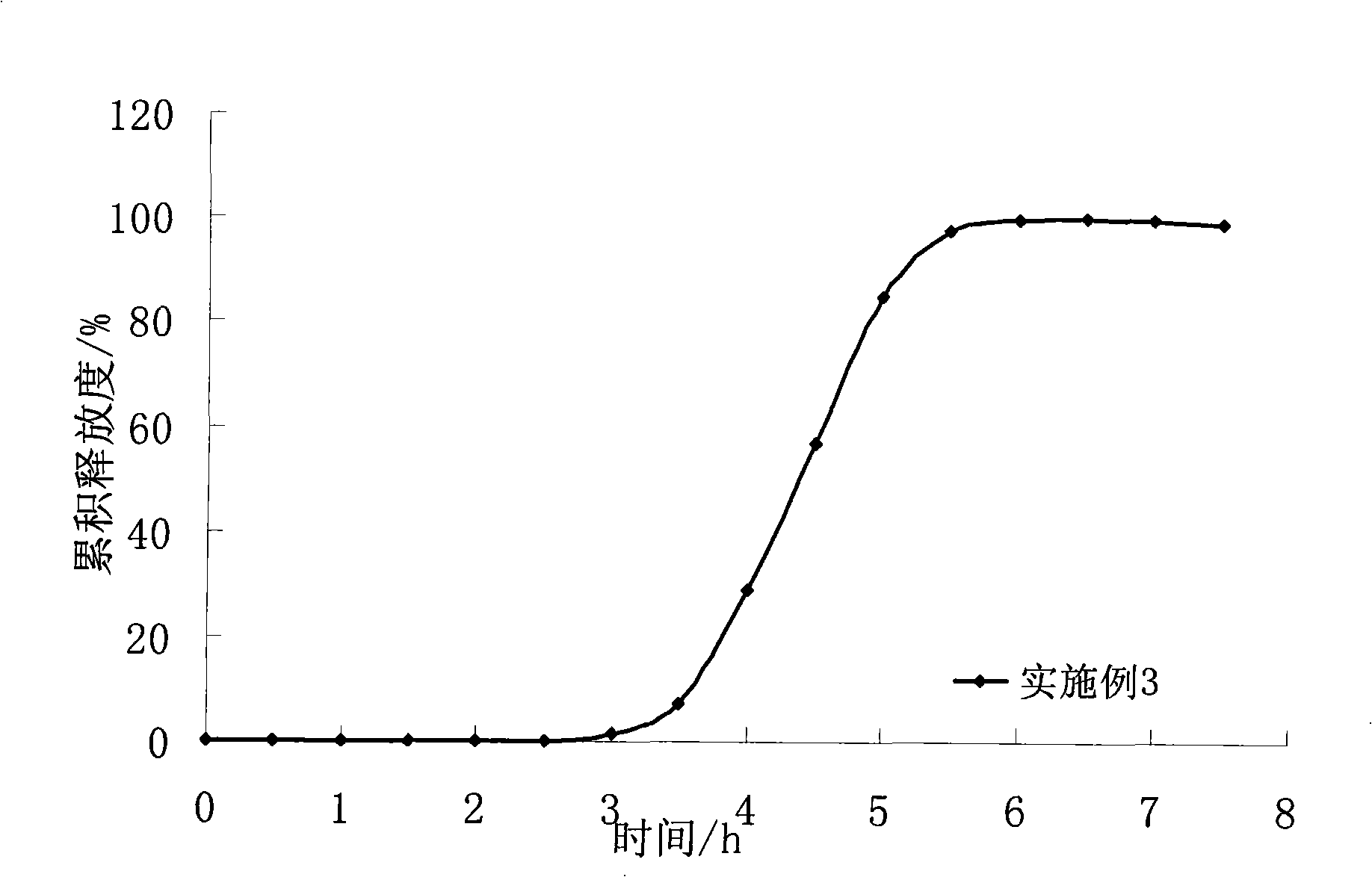

Embodiment 3

[0054] Whole medicated immediate-release pellet core formulation w / w(%)

[0055] Isosorbide dinitrate 30

[0056] Low-substituted hydroxypropyl cellulose 40

[0057] Microcrystalline Cellulose 30

[0058] Preparation process: add 5% HPMC in 70% ethanol solution to make soft material, extrude the soft material through the sieve plate of the extruder (aperture 0.8mm), put the strip-shaped particles in the spheronizer and spheronize, and dry the pellet core at 50°C After 5 hours, sieve the 18-24 mesh drug core to obtain the drug-containing immediate-release pellet core. The average cumulative dissolution rate was 5% in 45 minutes.

[0059] Basic layer: sodium carbonate 10% (w / v), add water to 100%, the coating process is the same as in Example 1. Coating weight gain 25%;

[0060] Hysteresis layer prescription w / v(%)

[0061] Polyacrylic resin III (Eudragit S100) 8

[0062] Dibutyl sebacate 1

[0063] Glycerin 0.2

[0064] Talc 1.5

[0065] Add 95% ethanol to 100%, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com